A combined installation method of steel structure roof purlins and support rods for industrial workshops

A technology for combined installation of industrial plants, which is applied in the direction of building construction, construction, and building material processing, can solve problems such as installation inconvenience, and achieve the effects of improving installation efficiency, improving labor efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The combined installation method of purlins and support rods for the steel structure roof of an industrial factory building is used for a 30m-span steel structure and a factory building with a conventional 12m column spacing. After the roof truss beam 3 is installed in place, it is characterized in that it includes the following steps:

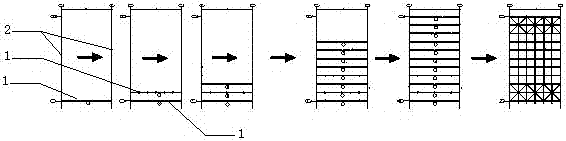

[0034] a. Connect the roof purlin 1 and the support rod 2 into an independent hoisting unit

[0035] According to the steel structure roof design of the factory building, it is divided into 5 independent hoisting units.

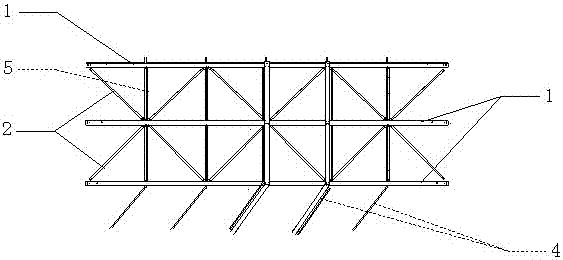

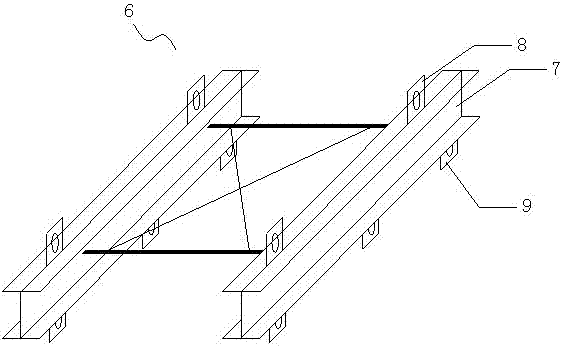

[0036] see now figure 2 , figure 2 It is a structural schematic diagram of an independent hoisting unit with three purlins 1 according to an embodiment of the present invention. As shown in the figure, each independent hoisting unit is made by connecting and fixing roof purlins 1 and support rods 2 horizontally. Each independent hoisting unit has 3 purlins arranged in parallel and 2 support rods 2. Between the pur...

Embodiment 2

[0043] This embodiment is used for a factory building with a steel structure spanning 30m and a column spacing of 18m. Except that the length of the H-shaped steel is 6m, the others are the same as in Embodiment 1.

[0044] The present invention has substantive features and significant technical progress. The combined installation method of steel structure roof purlins and support rods of industrial workshops of the present invention changes the traditional industrial workshop steel structure roof purlins and support rods from one-by-one hoisting to independent unit integral hoisting. , so that the installation and construction process is simple, and the installation efficiency is doubled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com