Gas-steam combined system and operation control method thereof

A combined system and gas-steam technology, applied in the energy field, can solve problems such as long payback period, unfavorable promotion, and increased initial investment of power plants, and achieve the effects of improving thermal efficiency, reducing impact, and reducing drainage temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

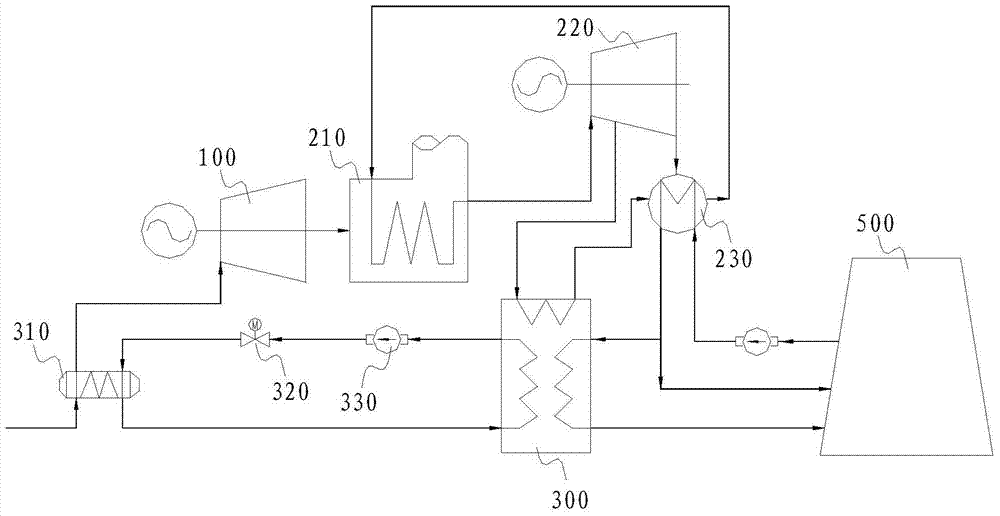

[0025] Such as figure 1 As shown, the combined gas-steam system includes: a gas turbine 100 , a steam cycle loop, an absorption heat pump 300 , and a preheating heat exchanger 310 . Among them, a waste heat boiler 210, a steam turbine 220, and a condenser 230 are arranged on the steam circulation circuit, and a steam extraction port is arranged on the steam turbine 220; the absorption heat pump 300 has a matching first heat exchange channel, a second heat exchange channel channels, and drive heat source channels; the preheating heat exchanger 310 has a third heat exchange channel and a fourth heat exchange channel; the inlet of the drive heat source channel is docked with the steam extraction port, and the outlet of the drive heat source channel is connected to the condenser The steam inlet of 230 is docked; the inlet of the first heat exchange channel is connected with the cooling water outlet of the condenser 230, and the outlet of the first heat exchange channel is connecte...

Embodiment 2

[0035] The difference between embodiment two and embodiment one is:

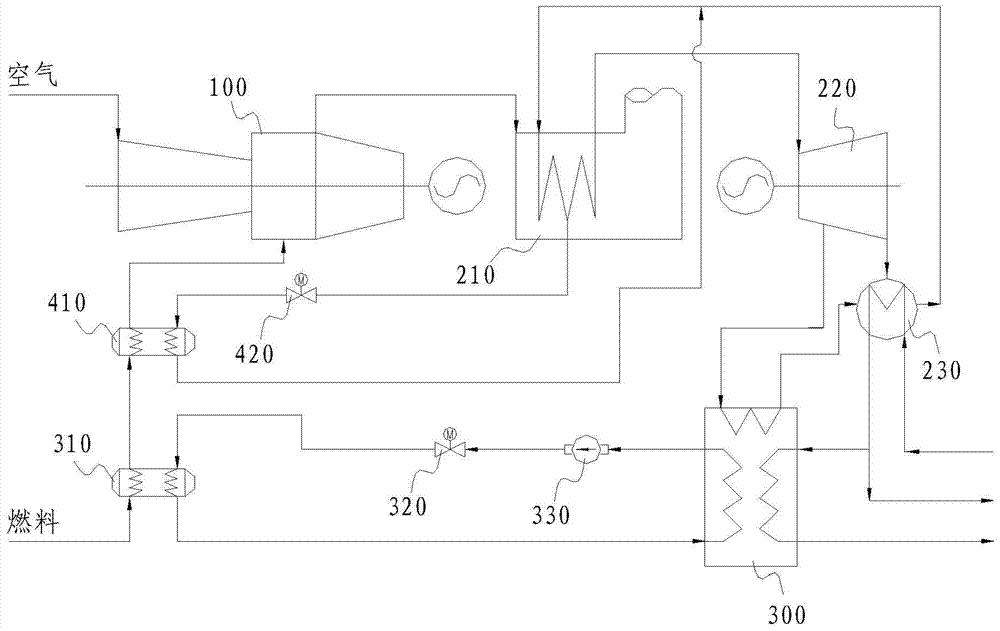

[0036] Such as figure 2 As shown, the absorption heat pump is not connected to the cooling tower, but directly connected to the ambient cold source such as the river. Due to the utilization of the low-grade energy of the cooling water of the condenser through the absorption heat pump, the temperature of the cooling water discharged to the outside is reduced to 25°C to 35°C, which has little impact on the environment and ecology and can be discharged directly.

[0037] The inlet of the fourth heat exchange channel is connected to the fuel source, and the preheating heat exchanger 310 heats the fuel entering the gas turbine 100 .

[0038] The combined gas-steam system also includes a fuel heater 410. The fuel heater 410 has a matching fifth heat exchange channel and a sixth heat exchange channel. The pumping port is connected, the outlet of the fifth heat exchange channel is connected to the feed water inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com