A kind of anti-shock buffer mechanism of angular stroke cylinder

A buffer mechanism and anti-shock technology, which is applied to mechanical equipment, engine components, valve details, etc., can solve the problems of affecting the valve action efficiency and high design and manufacturing costs, and achieve obvious anti-shock and buffer effects, low manufacturing costs, and improved action. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

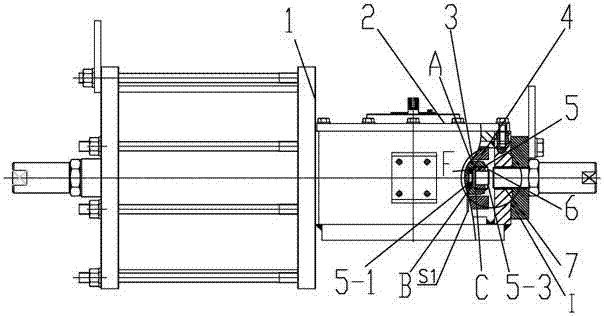

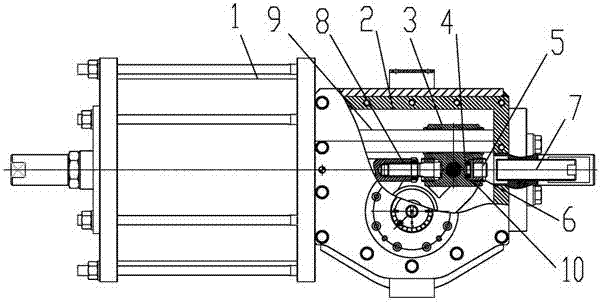

[0019] Such as Figure 1-5 Shown: a quarter-stroke cylinder anti-shock buffer mechanism, including a cylinder 1 and a casing 2, the casing 2 is provided with a piston rod 8 connected to the cylinder 1, and one end of the piston rod 8 is connected to the connecting block 3; The connecting block 3 slides on the guide rod 9; the end of the box body 2 is also provided with a limit bolt 7;

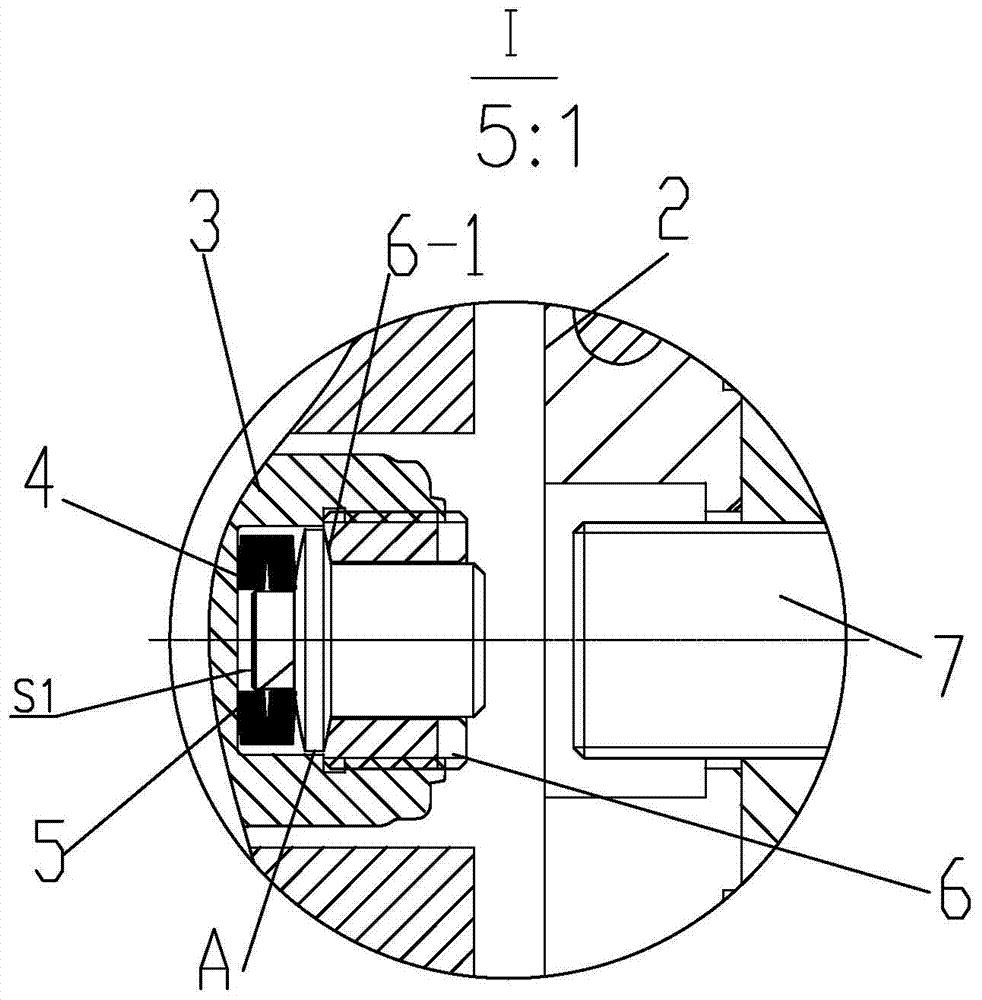

[0020] Described connection block 3 is provided with blind hole 10, is provided with several butterfly springs 4 in blind hole 10, is provided with buffer block 5 in the inner circle of butterfly spring 4, is also provided with round nut 6 in blind hole 10 , The buffer block 5 can move axially in the round nut 6 .

[0021] The bottom of the blind hole 10 is a flat end, and the butterfly springs 4 are divided into groups facing oppositely and placed at the flat ends of the bottom of the blind hole 10 according to the needs of different pre-tightening forces and strokes; the outer circle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com