Heat pipe flue gas waste heat recycling device and working medium

A flue gas waste heat recovery device technology, which is applied to indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of poor heat transfer effect, and achieve the effects of easy replacement, quick disassembly, and superior heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

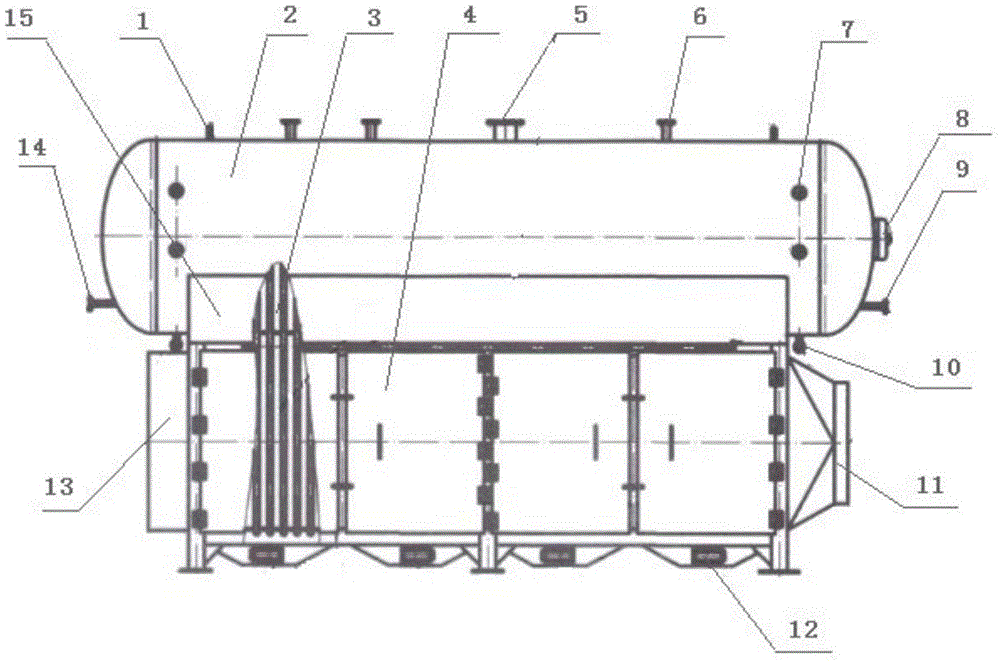

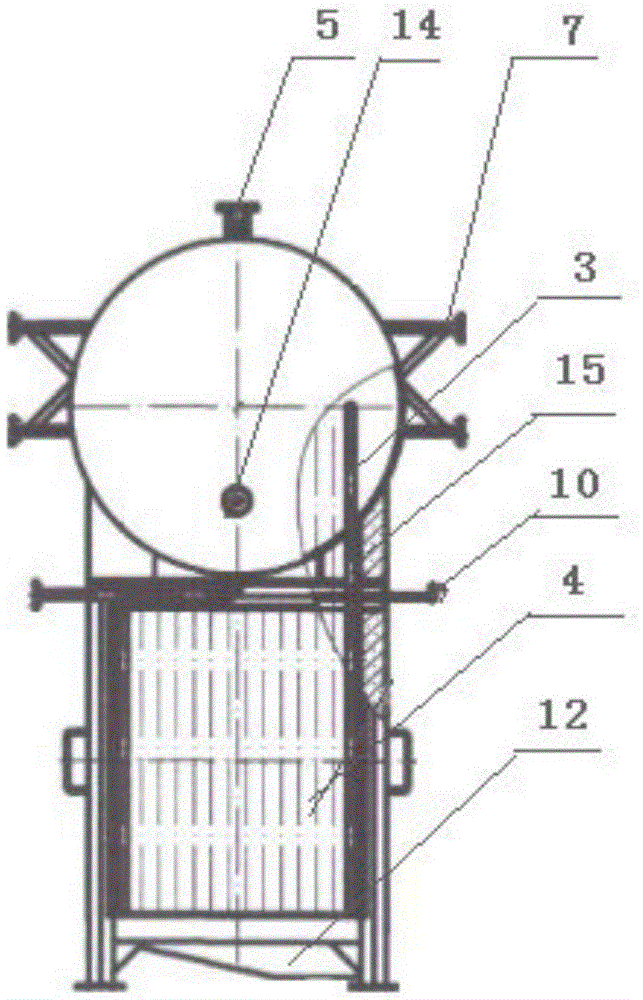

[0024] A heat pipe flue gas waste heat recovery device, comprising a steam generating tank 2, a heat pipe assembly 3, and a flue gas channel 4, the flue gas channel is a direction frame, one side is an air inlet 13, and the other side is an air outlet 11, and the The lower part of the flue gas channel is equipped with a plurality of ash removal ports 12 at intervals. A steam generating tank is installed on the upper part of the flue gas channel. The two sides of the steam generating tank are fixed on the upper part of the flue gas channel through connecting plates 15. The two ends of the heat pipe assembly are installed through the seal, the heat pipe evaporation section is in the flue gas channel, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com