Optimization method for heat-engine plant thermal on-line process identification and control algorithm based on dual-objective parallel ISLAND-HFC mixed model genetic programming algorithm

A hybrid model and genetic programming technology, applied in the field of thermal automation intelligent control and evolutionary computing, can solve the problems of increased algorithm operation cost and reduced efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

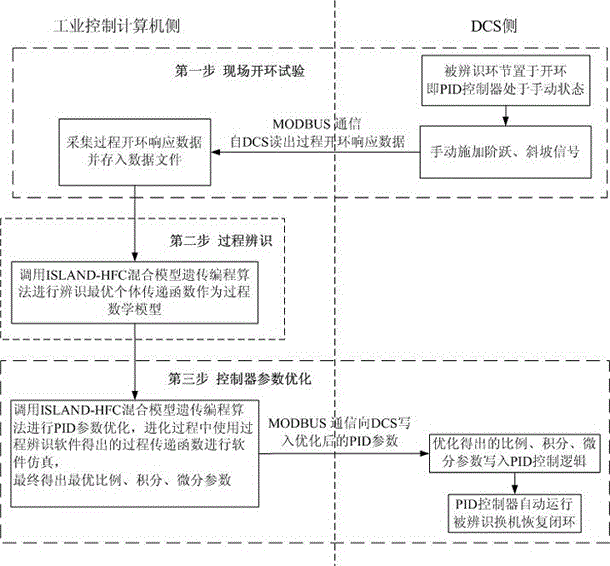

[0198] Attached below figure 1 - attached Figure 15 And embodiment further illustrate the present invention.

[0199] The concrete steps of embodiment are as follows:

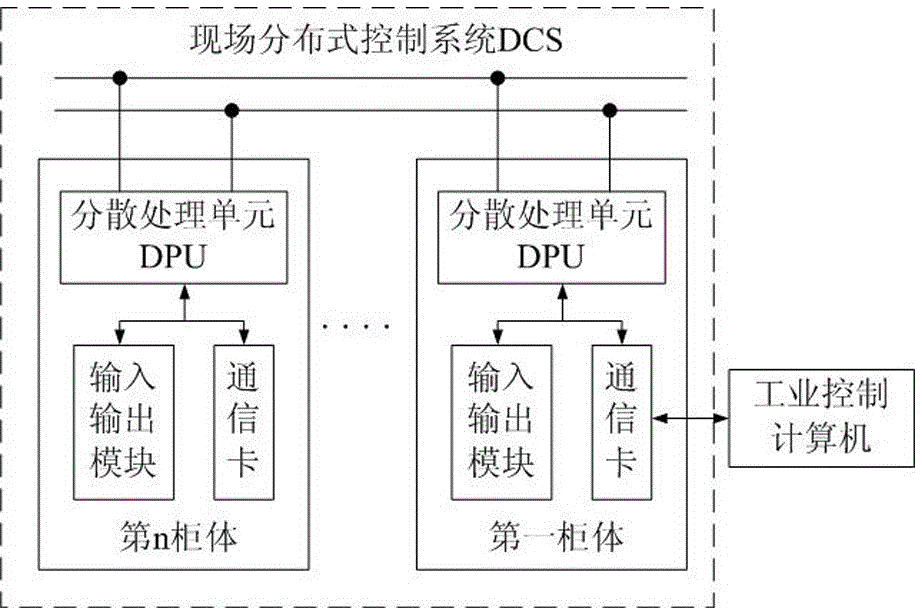

[0200] 1. Build a hardware platform (see figure 1 )

[0201] The hardware platform includes a field distributed control system DCS and an industrial control computer; the distributed processing unit DPU in each cabinet of the field distributed control system DCS is connected by a DCS field bus double-redundant communication network; the field distributed The distributed processing unit DPU, input and output modules or communication cards in each cabinet of the control system DCS are connected through the communication bus in the DCS cabinet; the communication card in the first cabinet is connected to the RS485 serial communication port of the industrial control computer; The industrial control computer has a dual-core or above CPU; the communication card adopts a MODBUS communication card;

[0202] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com