High voltage shunt circuit for ignition system

A technology of ignition system and shunt circuit, which is applied in the direction of control/regulation system, electrical components, and adjustment of electrical variables, to achieve the effects of reducing the probability of misfire, increasing ignition energy, and prolonging discharge time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

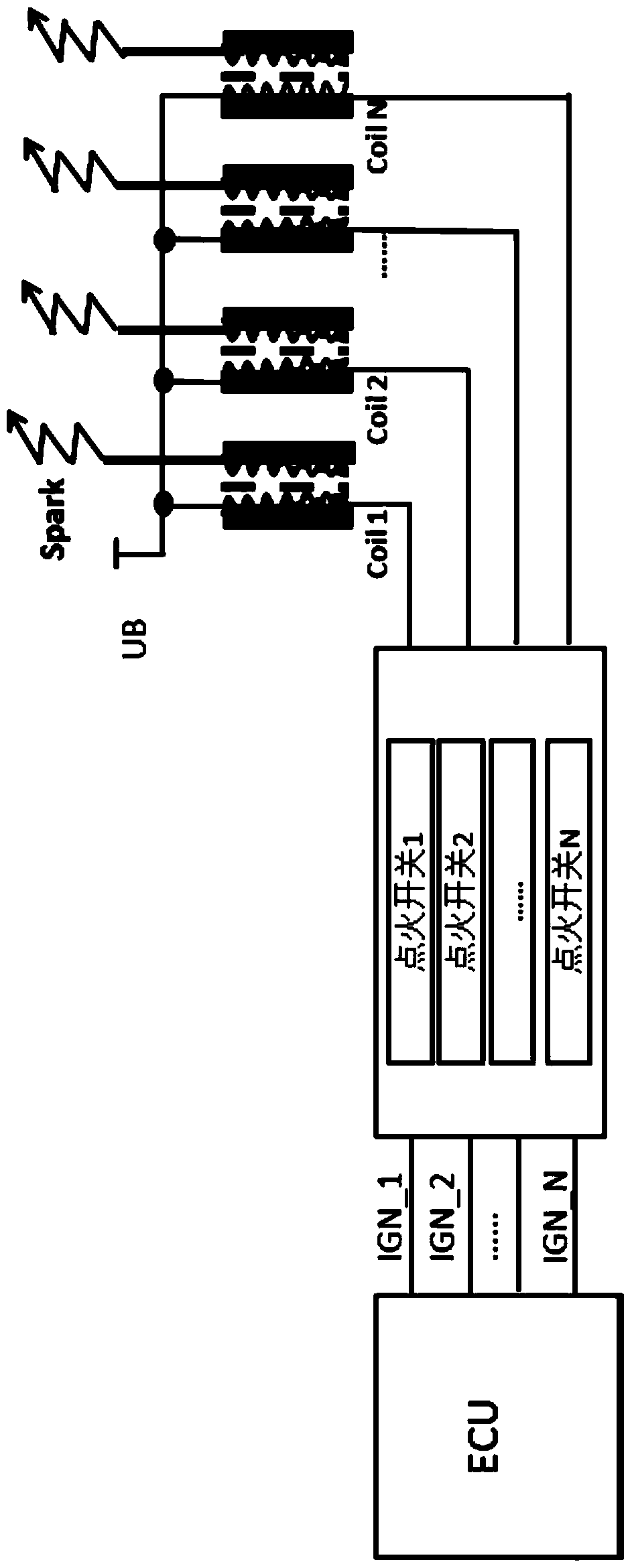

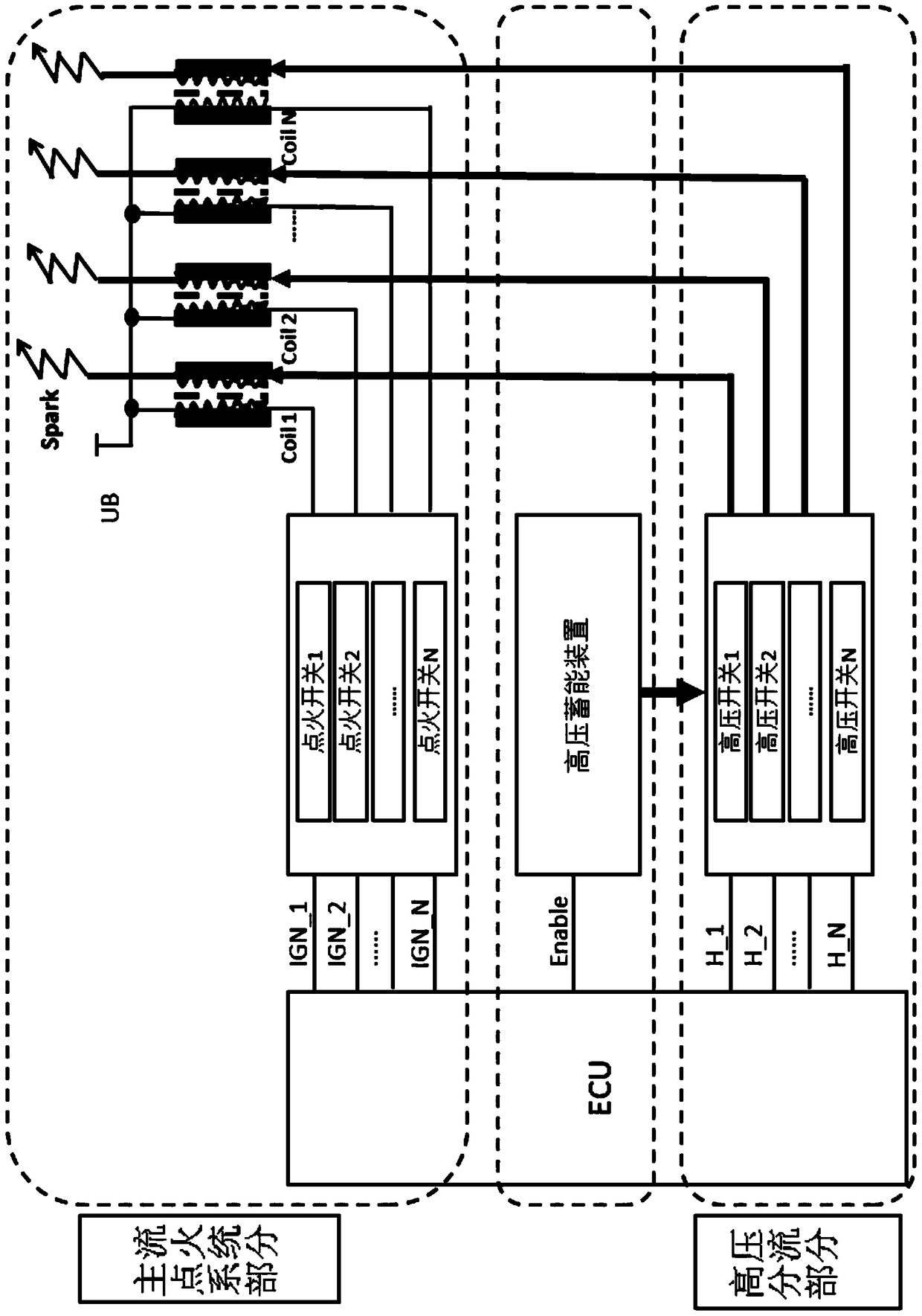

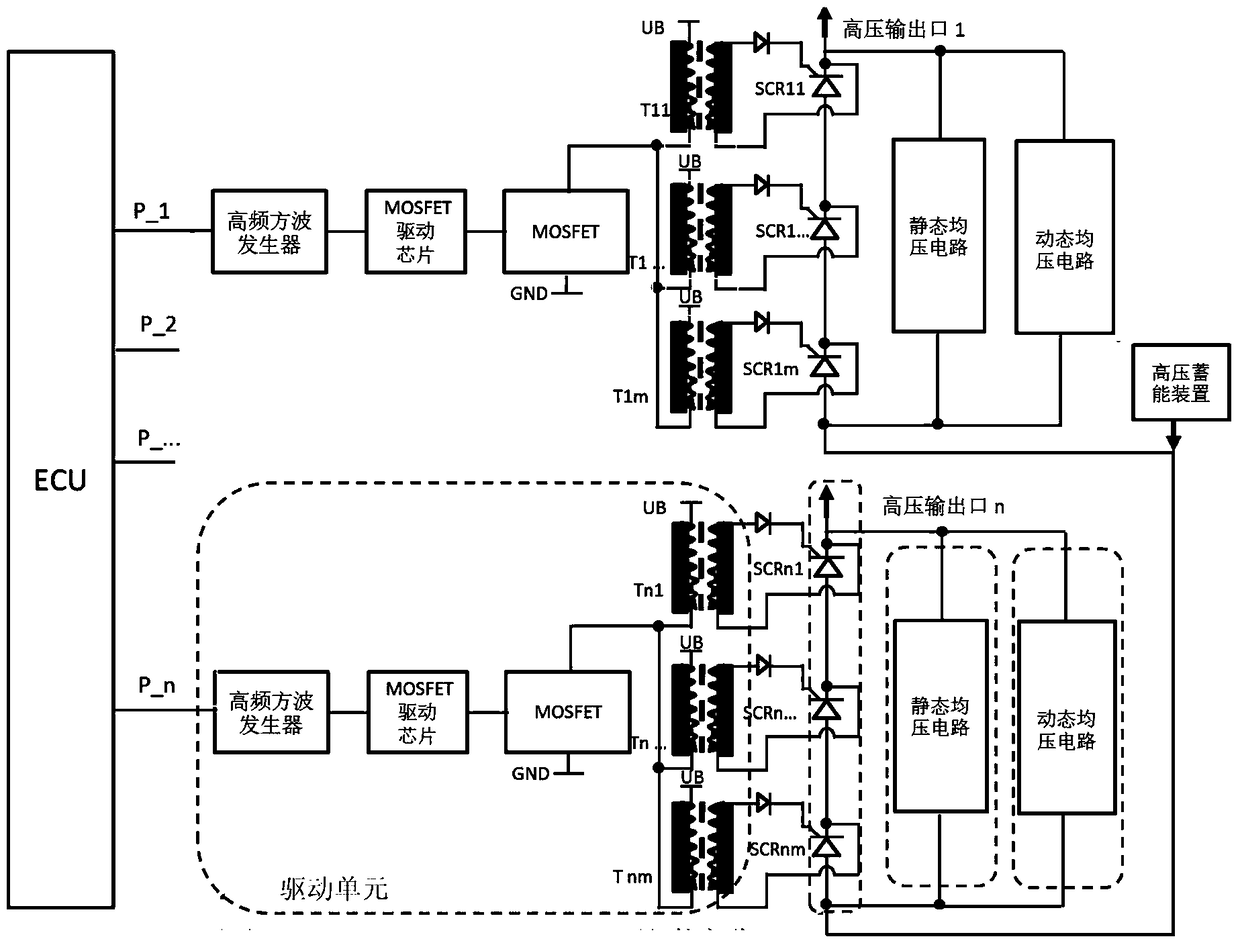

[0017] The high-voltage shunt circuit for ignition system of the present invention is suitable for ignition systems with high-voltage energy storage devices, such as figure 2 As shown, a high-voltage energy storage device is connected to the secondary coil of the corresponding ignition coil through several high-voltage switches, and the ECU controls the opening of the high-voltage switch of the corresponding ignition coil, so that the high-voltage energy storage device can continue to flow for the secondary coil in turn. Since all ignition coils share a high-voltage energy storage device, which can generate thousands of volts of high voltage, each ignition coil is equipped with a high-voltage shunt circuit, which is equivalent to a high-voltage switch, such as image 3 As mentioned above, it includes a drive unit and some thyristors,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com