Machine design comprising a pivotable tool spindle

A technology for processing machine tools and spindles, which is applied in the direction of metal processing machinery parts, machine tool parts, metal processing equipment, etc., can solve the problems of structure cost and cost, and achieve the effect of high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In the figures, elements that are identical or correspond to one another are marked with the same reference numerals and are therefore not described again as long as this does not serve the purpose. The disclosure content contained in the entire description can be transferred without meaning to the same parts with the same reference signs or the same component designations. Positional indications selected in the description, such as top, bottom, sideways, etc., refer to the immediate description and the illustrated figure and can be transferred to the new position in the event of a position change. Furthermore, individual features or combinations of features from the various exemplary embodiments shown and described constitute per se independent, inventive or inventive solutions.

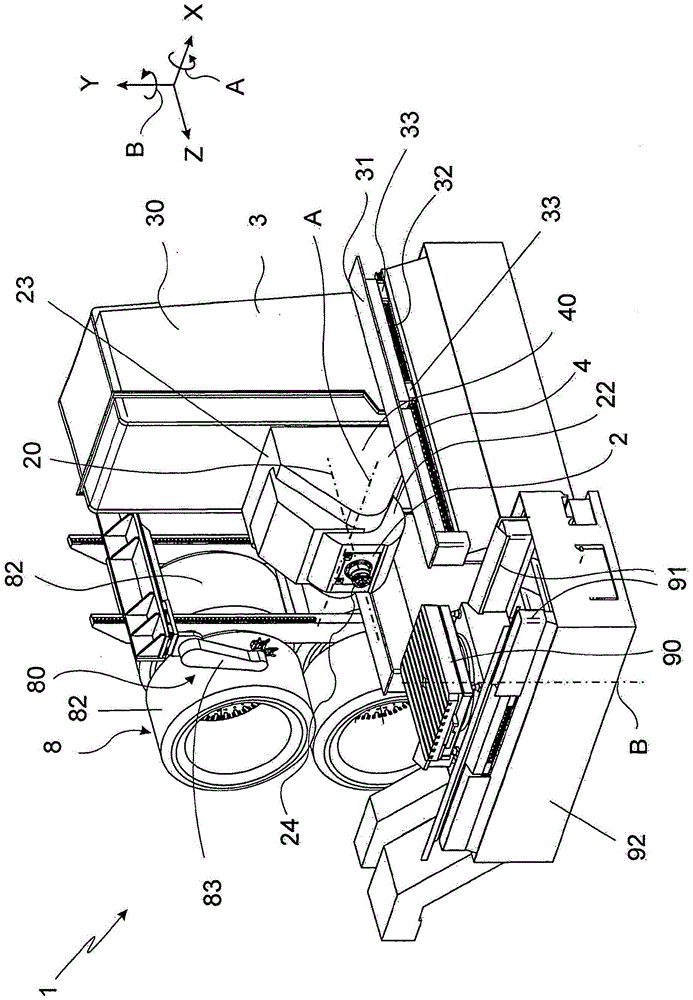

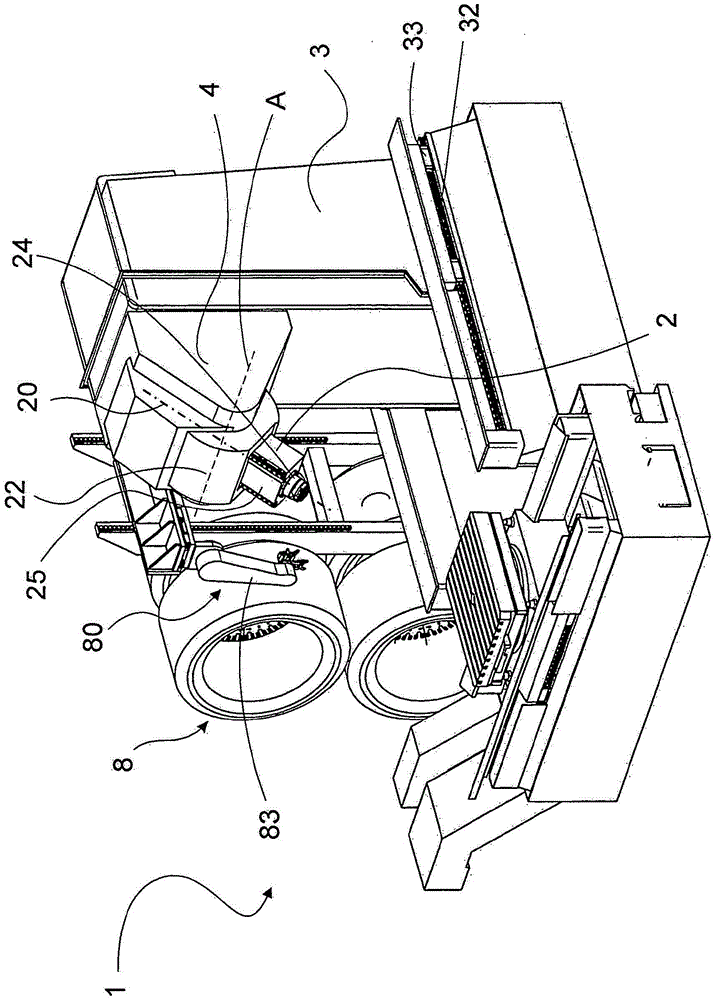

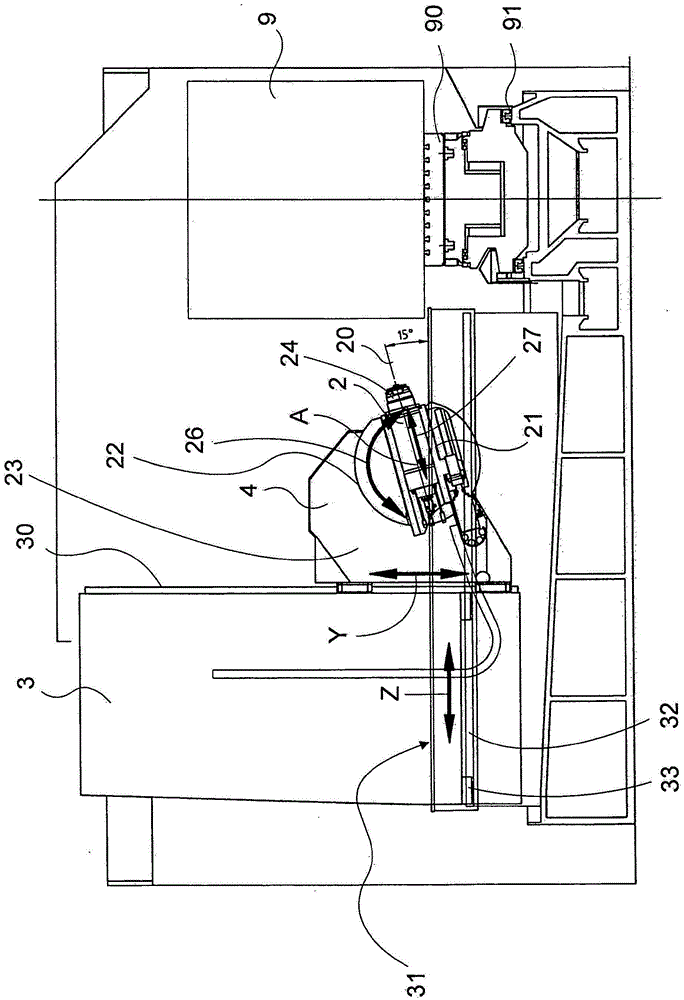

[0054] exist Figure 1a , b shows by way of example that the processing machine tool 1 is in two different processing positions. The processing machine tool 1 is used for machining a workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com