An online cleaning device and a complete set of membrane silk gel shaping equipment including the device

A technology for cleaning devices and complete sets of equipment, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of many manpower interventions, obvious time costs, water consumption, etc., and achieve short processing cycles , Reduce the probability of damage to the membrane filament, and the effect is very easy to promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

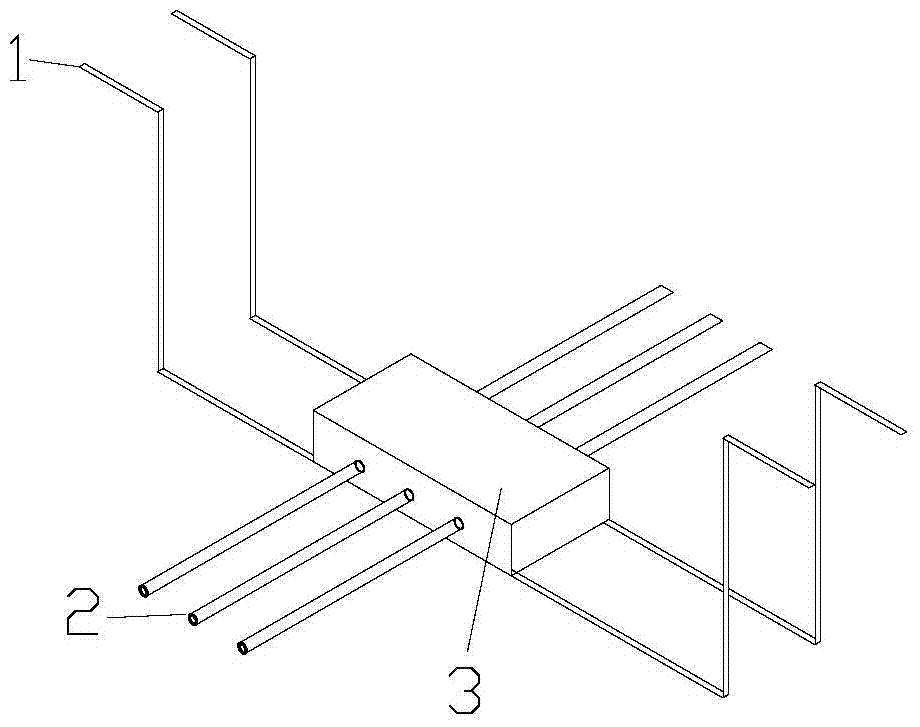

[0031] Such as figure 1 An online cleaning device shown mainly includes a fixing frame 1, a membrane filament cleaning tube 2 and a solution collection chamber 3. The online cleaning device is connected to the gel tank currently only used for preliminary shaping of the membrane filament through the fixing frame 1. The solution collection chamber 3 is placed on the fixed frame 1, and several groups of membrane filament cleaning tubes 2 are arranged in the solution collection chamber 3, and each group of membrane filament cleaning tubes 2 includes two membrane filament cleaning tubes installed on both sides of the solution collection chamber 3 along the same straight line. Tube 2; where:

[0032] The fixing frame 1 is not limited to the bracket-type fixing structure in this embodiment, it can also be made into a base-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com