Vacuum insulation induction heating furnace for forging

An induction heating furnace and vacuum heat preservation technology, applied in forging furnaces, furnaces, furnace types, etc., can solve the problems of high heat utilization rate and high uniformity of induction heating, and achieve the effects of high heating efficiency, labor saving and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

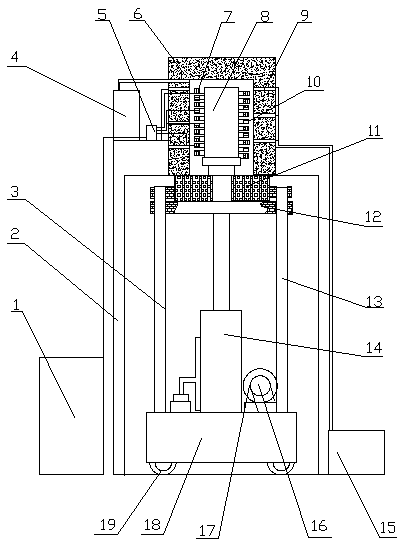

[0022] As shown in the drawings: a vacuum insulation induction heating furnace for forging, including a heating part and a workpiece entry and exit part, the heating part includes an induction heating device 7, a vacuum system 4, and the induction heating device 7 includes a bracket 2 and a vacuum insulation cover 6 , the induction coil 10 and the thermometer 9, the vacuum insulation cover 6 is located at the upper end of the support 2, the vacuum insulation cover 6 is open at the lower end, the induction coil 10 is in the vacuum insulation cover 6, and the thermometer 9 is evenly distributed on the vacuum insulation cover 6, The vacuum system 4 communicates with the vacuum insulation cover 6, and the vacuum system 4 is a vacuum pump; the workpiece entry and exit part includes a lifting mechanism 3, an entry and exit drive mechanism 16, and an operating trolley 18, and the lifting mechanism 3 is fixed above the operating trolley 18, and the lifting mechanism 3 A workpiece place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com