Automatic memory bar assembling machine for computer mainboard assembling

A memory stick, memory technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of wasting manpower, low yield, low efficiency, etc., to improve yield, high controllability, and improve labor productivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

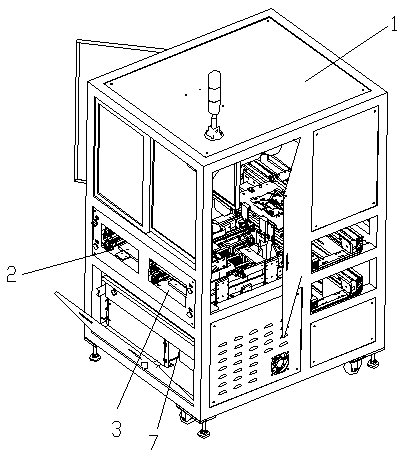

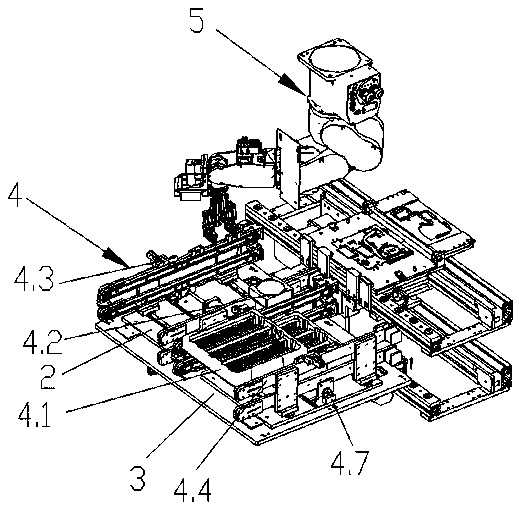

[0028] Such as figure 1 , figure 2 As shown, the present invention includes a case 1, the side of the case 1 is provided with a memory stick entrance, and also includes a material loading input system 4, a robot grabbing system 5, a motherboard carrier transmission system 6 and a control system 7 arranged in the case 1.

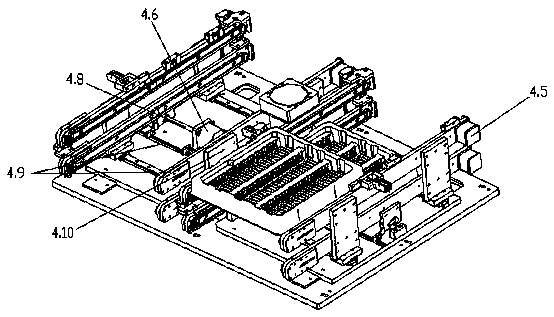

[0029] Such as figure 2 , image 3 As shown, the material carrying input system 4 includes two double-layer belt tracks 4.4 arranged side by side, a material tray 4.1 arranged above the belt track 4.4, a CCD1 vision system 4.2 arranged between the two double-layer belt tracks 4.4, and a CCD1 vision system 4.2. The system 4.2 includes a camera and a light source, and the input end of the belt track 4.4 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com