Multi-station assembly equipment for assembling vehicle components

A technology for assembling equipment and vehicle parts, which is applied in the direction of metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of increasing equipment complexity, increasing machine costs, increasing labor costs, etc., to improve implementability and reduce movement The effect of less time, manufacturing and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

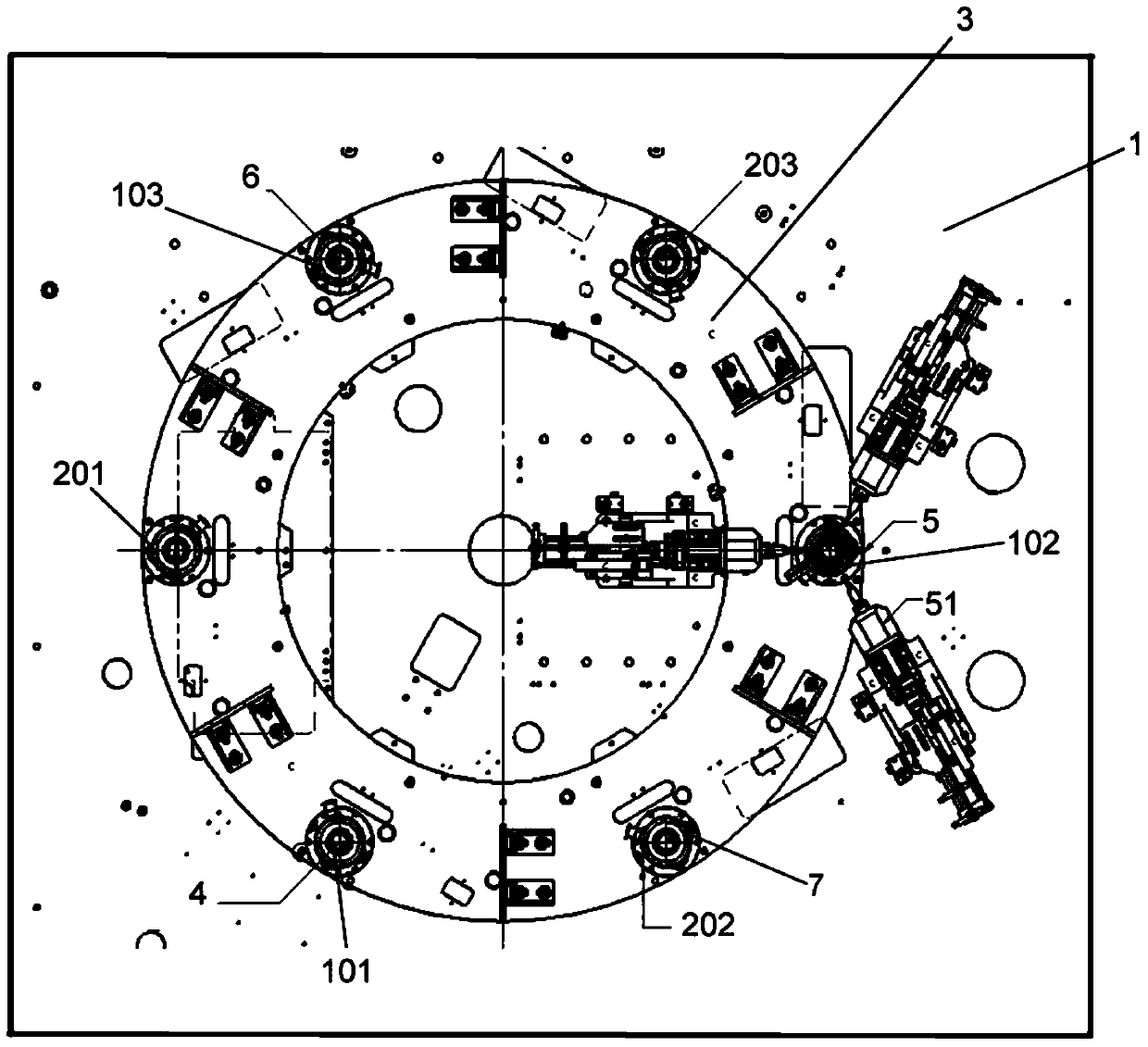

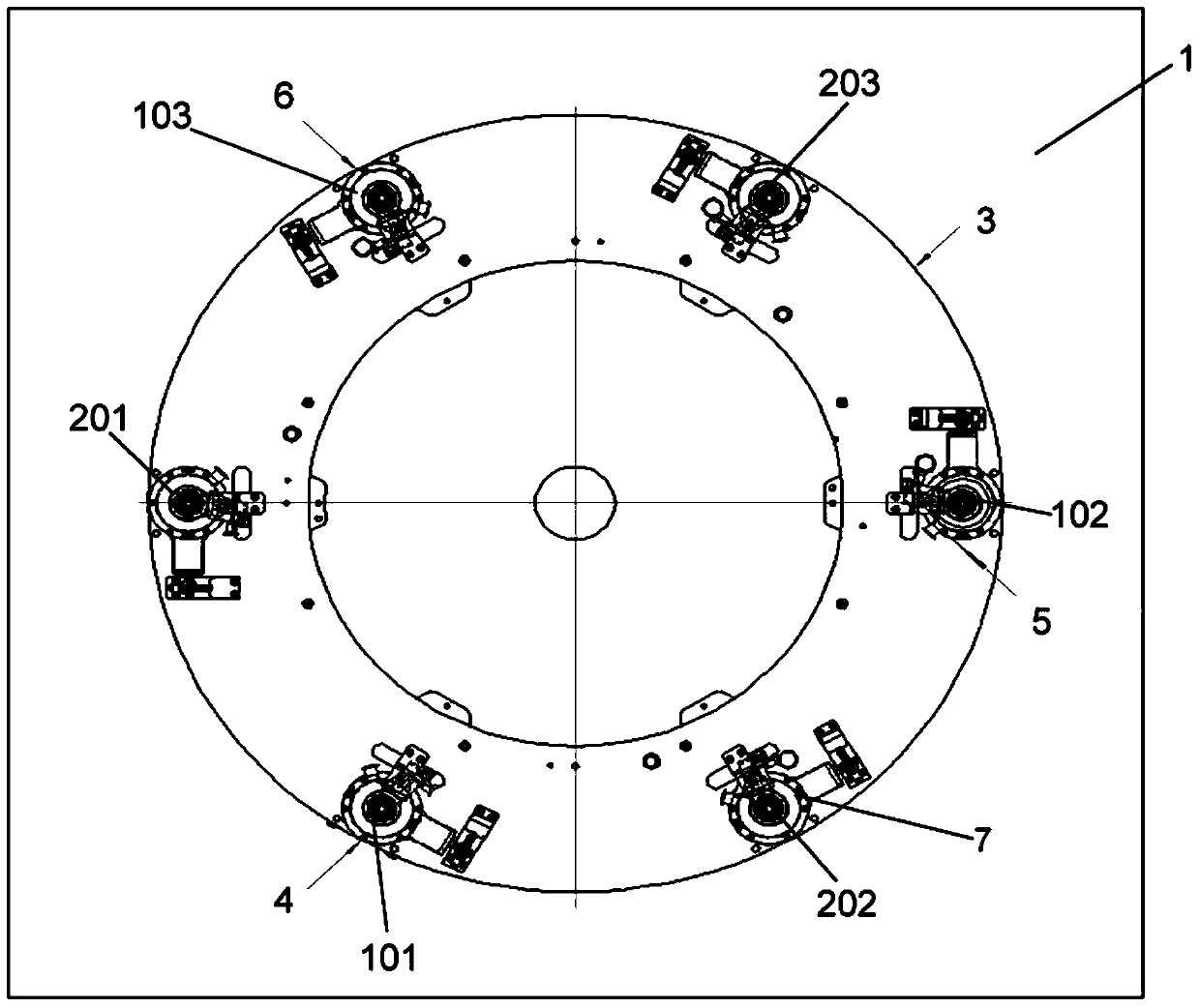

[0029] Hereinafter, embodiments of multi-station assembly equipment according to the present invention will be described with reference to the accompanying drawings. The same or similar features in the drawings will be denoted by the same reference numerals, and repeated explanations thereof will be omitted.

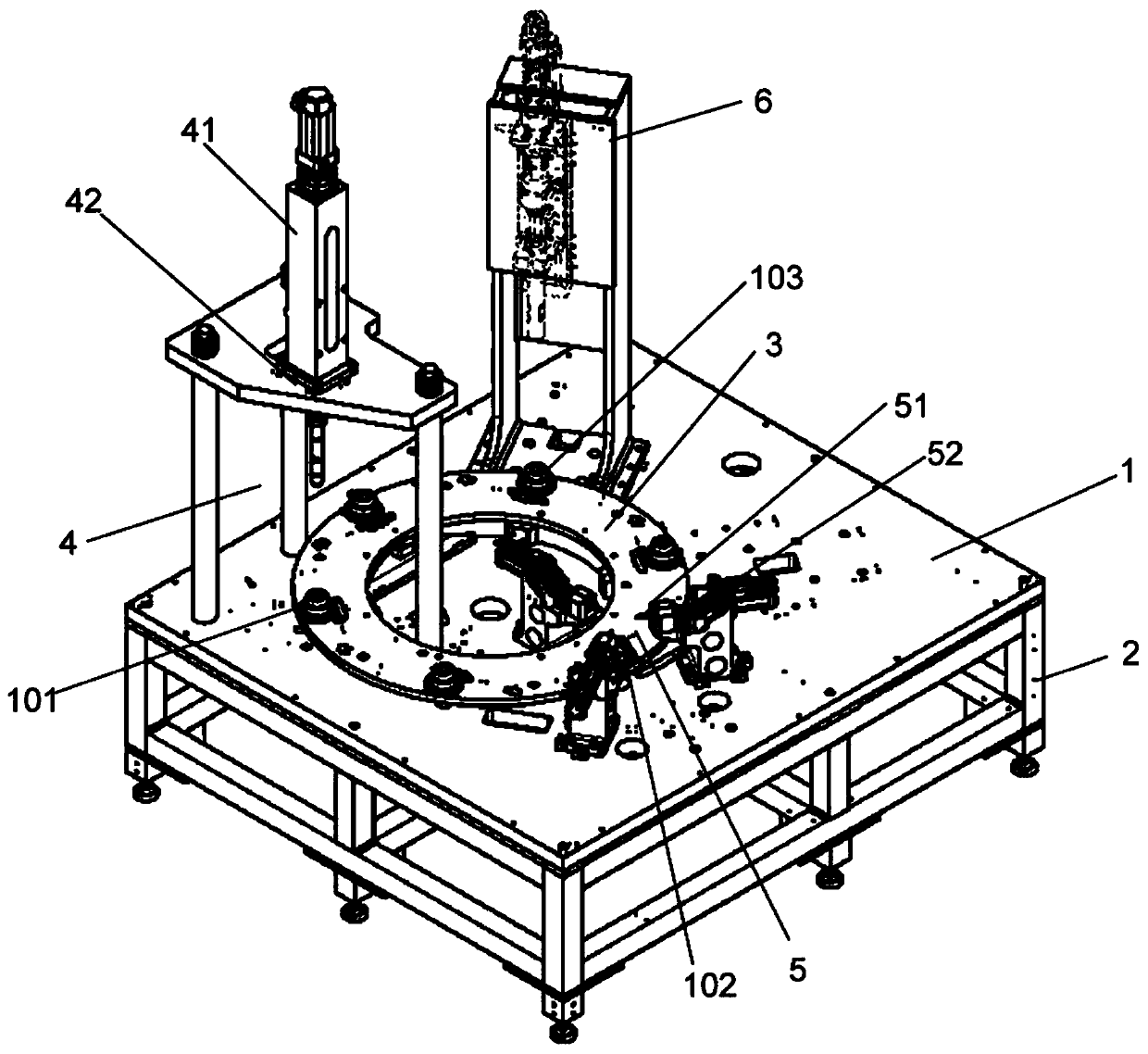

[0030] figure 1 It schematically shows a perspective view of a multi-station assembly device according to an embodiment of the present invention, the multi-station assembly device is used for assembling a sensor unit of a vehicle electric power steering system. like figure 1 As shown, the multi-station assembly equipment has a workbench 1 provided with a horizontal work surface, and the workbench 1 stands on the ground through a bracket 2 . The transfer table 3 is rotatably supported on the horizontal working surface of the workbench 1. In this embodiment, the transfer table is provided in the form of a turntable 3, and the turntable 3 rotates around its central axis, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com