Multifunctional main frame assembly tire

A technology for main frame and tire assembly, which is applied in the field of assembly equipment for large steel structures, to achieve the effects of expanding the scope of application, easy promotion, and novel ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

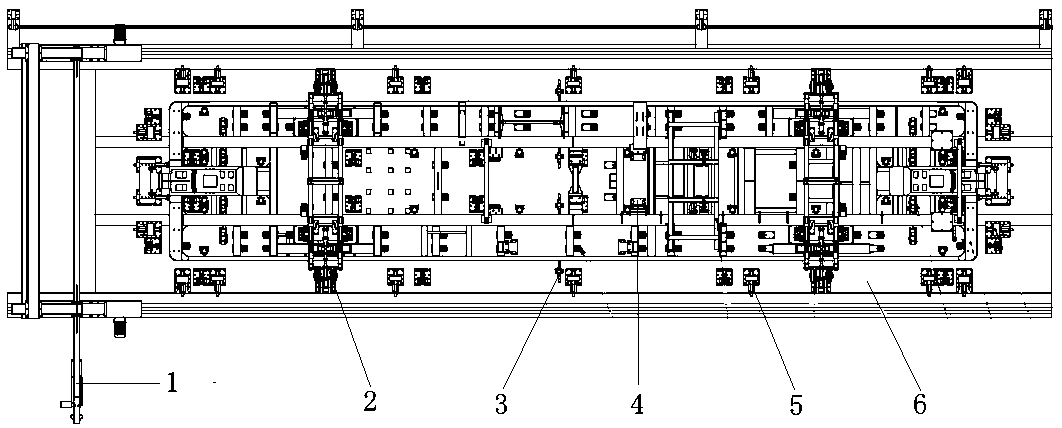

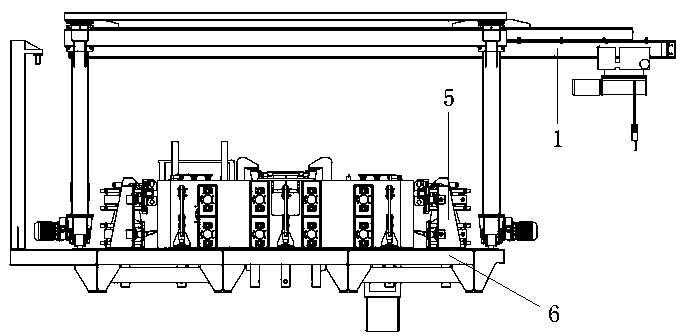

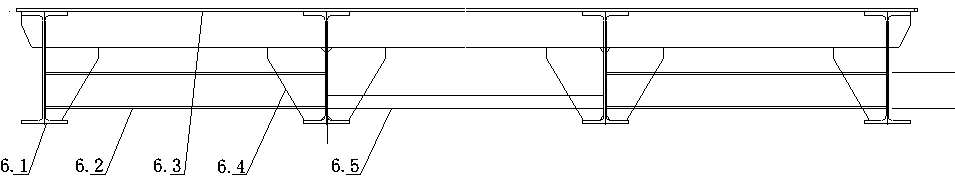

[0031] A multi-functional main frame assembly tire, comprising a base base 6, a positioning unit 4, a component position limiting and pressing mechanism 5, a centering marking device 3, an accessory accompanying fixture 2 and a gantry type accessory hanger 1, and the base base 6 is provided with There is a gantry-type accessory crane 1 that can walk along the foundation base. The workpiece to be assembled is arranged on the foundation base 6. A centering marking device 3 is fixed on the base base 6 in the middle of the outer side of the workpiece to be assembled. The inner side of the workpiece to be assembled A positioning unit 4 is fixed, a number of component position-limiting and pressing mechanisms 5 are evenly arranged on the sides of the base base 6 , and accessory accompanying fixtures 2 are provided on relevant positions of the workpiece to be assembled.

[0032] Assembling each group of related parts on the tire, its positioning and clamping mechanism is made as a mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com