A kind of asphalt wet forming device and forming process

A technology of wet forming and asphalt, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of complex process, high cost, and large dust in the production site, and achieve short process, uniform spherical particles, and equipment investment. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

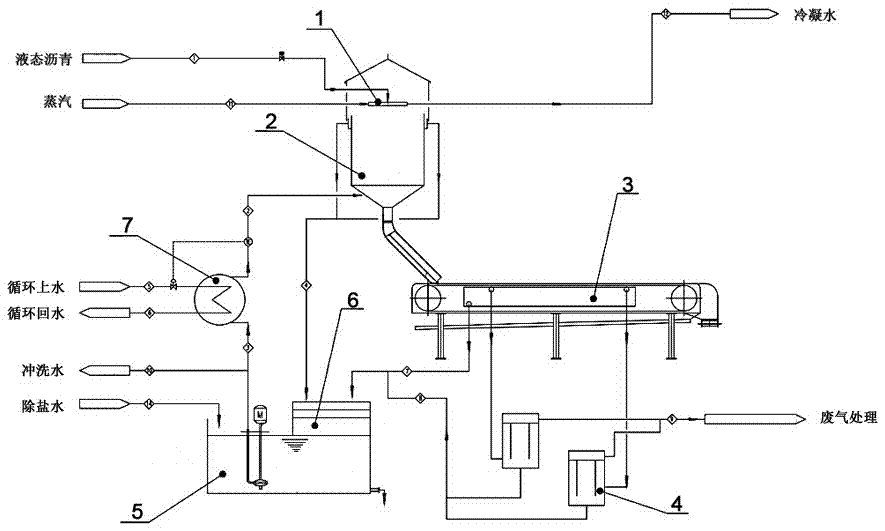

[0018] As shown in the figure: an asphalt wet forming device, including a forming plate 1, a forming tank 2, a dehydration conveyor 3, a gas-water separator 4 and a hot water tank 5, the forming tank 2 is a tank body with an open top, The lower side wall of the forming tank 2 is provided with a water inlet, the bottom of the forming tank 2 is provided with a forming asphalt outlet, the forming disc 1 is arranged above the forming tank 2, and the upper part of the forming tank 2 is provided with an overflow port, and the overflow port passes through the pipeline Connected to the hot water tank 5, the tank body of the forming tank 2 is provided with an observation window and a cleaning port. Forming tray 1 is an open container with pores (diameter of 2mm-5mm) at the bottom, and heating steam coils are installed on the outer wall and bottom of forming tray 1 (to keep the temperature of the liquid pitch in it at 260°C to 280°C). The asphalt outlet at the bottom of the forming tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com