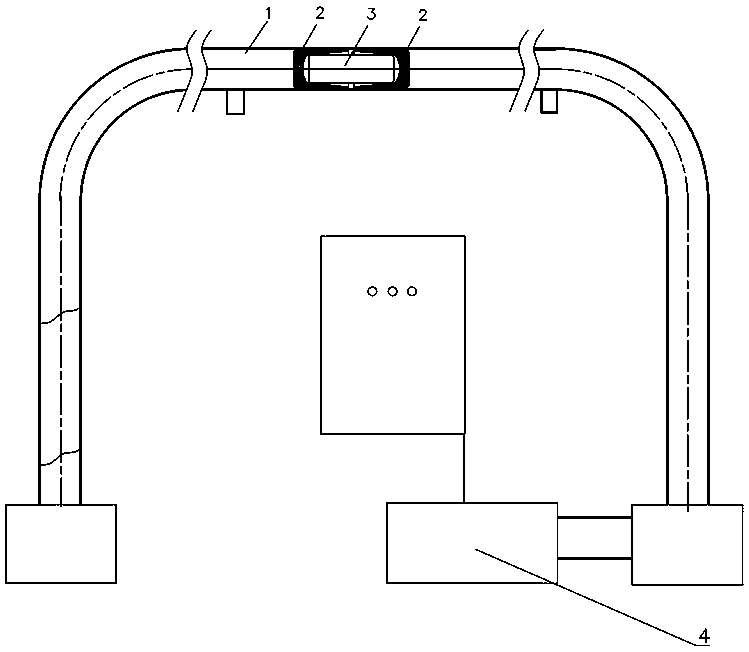

A piston sheath device for pneumatic conveying of materials

A pneumatic conveying and pneumatic conveying technology, applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of high cost of use, sample bottle damage, high maintenance cost, etc., and achieve low cost, simple production process, and guaranteed physical characteristics and precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0039] Specific embodiment 1: as Figure 4 and Figure 5 As shown, in this embodiment, the other end of the piston sheath body 2 is provided with a foreign matter removal part 24. The foreign matter 5 in the transmission pipe 1 is pushed and removed out of the pipe under the action of thrust. In this embodiment, the foreign matter removal part 24 includes a shovel-shaped edge provided on one end of the piston sheath body 2 , and the shovel-shaped edge is arranged along the circumference of the piston sheath body 2 .

[0040] When there is a foreign object 5 in the pipeline (the foreign object 5 may be sample residue, sample leakage, or ice cubes, because when the temperature is very low, the inner wall of the pneumatic transmission pipeline 1 is prone to condensation of gas into ice), the high-speed The foreign matter removal part 24 of the conveying piston sheath body 2 can scoop up the foreign matter 5 in the pipeline and push it forward until it is cleared out of the pipe...

specific Embodiment 2

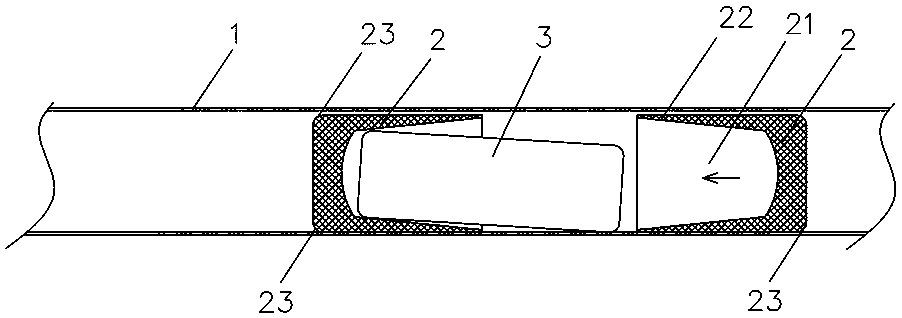

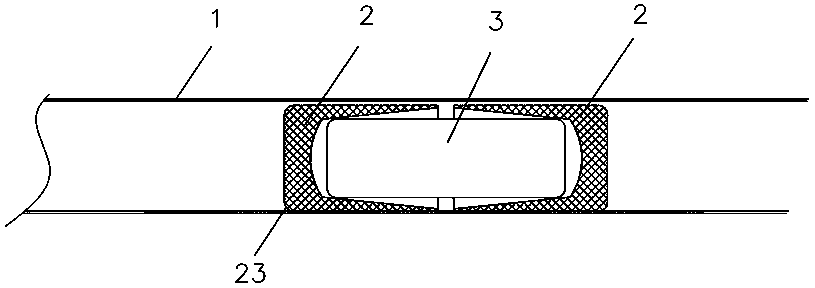

[0041] Specific embodiment 2: as Image 6 As shown, in this embodiment, the piston sheath body 2 is a two-way driving piston sheath, and both ends of the piston sheath body 2 are provided with matching protective chambers 21 and guide parts 22, that is, the piston sheath body 2 Both ends can carry and protect an object 3 to be conveyed. The operator can set a piston sheath body 2 in the pneumatic transmission pipeline 1 to push or pull the object 3 to be conveyed to complete the pneumatic transmission; it is also possible to set more than two piston sheath bodies 2 in the pneumatic transmission pipeline 1 to sandwich the material to be transported. Conveyor 3 is conveyed pneumatically. At the same time, it is also possible to realize synchronous transmission of multiple objects to be conveyed 3 at the same time. It is only necessary to connect multiple piston sheath bodies 2 and multiple objects to be conveyed 3 in series, that is, to set each object to be conveyed 3 in two a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com