Device and method for producing electricity by utilizing polyacrylamide solution specially used for oil field

The technology of polyacrylamide and electric method is applied in the fields of resource utilization and energy recovery of petroleum production wastewater, which can solve the problems of increasing treatment cost, high emulsification degree, and increasing difficulty in treatment of produced water, and saves energy. , the effect of rapid power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

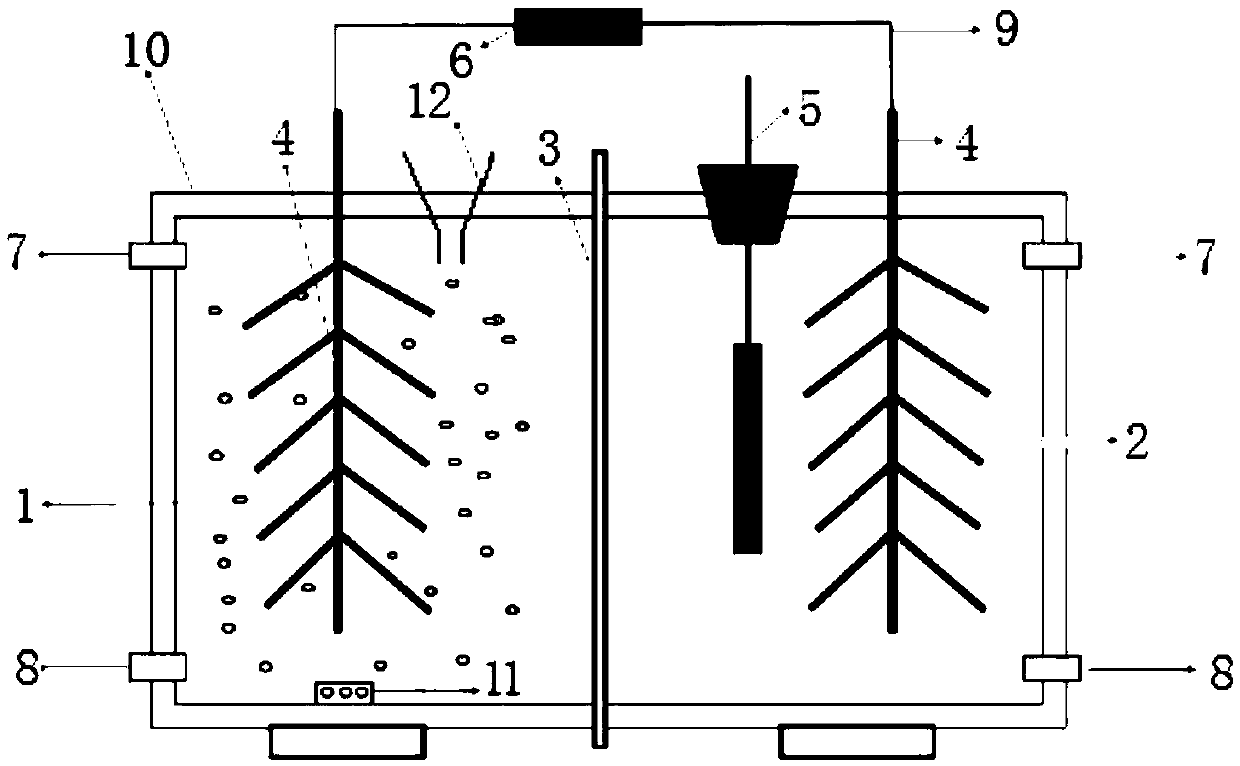

[0026] Specific implementation mode 1: Combination figure 1 To explain this embodiment, a device of this embodiment that uses polyacrylamide solution for oilfields to generate electricity is composed of cathode chamber 1, anode chamber 2, proton exchange membrane 3, titanium wire brush 4, reference electrode 5, and external It is composed of a resistor 6, two water outlets 7, two feed ports 8, a wire 9, a cavity 10 and an aeration head 11;

[0027] The inner cavity of the cavity 10 is divided into a cathode chamber 1 and an anode chamber 2 by a proton exchange membrane 3 arranged vertically in the middle position. The two ends of the proton exchange membrane 3 penetrate the upper top and the lower bottom of the cavity 10, and Located outside the cavity 10; in the cathode chamber 1 and the anode chamber 2 are respectively provided with titanium wire brushes 4, and one end of the two titanium wire brushes 4 respectively penetrate the top of the cavity 10 and located outside the cavi...

specific Embodiment approach 2

[0029] Specific implementation manner two: combination figure 1 To illustrate this embodiment, the difference between this embodiment and the first embodiment is that the wire connecting the reference electrode 5 penetrates the upper top of the anode chamber 2 and is sealed by a rubber plug. Other components and connection modes are the same as the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination figure 1 To describe this embodiment, the difference between this embodiment and the first embodiment is that the volume of the cathode chamber 1 and the anode chamber 2 are the same. Other components and connection modes are the same as the first embodiment.

[0031] Specific implementation manner 4: Combination figure 1 To explain this embodiment, a method for generating electricity by using a polyacrylamide solution for oilfields. The method is performed using the device described in the first embodiment. The specific operations are as follows:

[0032] 1. Inoculate the titanium wire brush 4 in the anode chamber 2 and the titanium wire brush 4 in the cathode chamber 1 with activated sludge capable of degrading refining wastewater, and then add acetonitrile to the anode chamber 2 and cathode chamber 1 respectively. For wastewater, the anode chamber 2 is sealed for 24 hours, and the cathode chamber 1 is continuously aerated fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com