Quartz bonding method based on gold-tin co-crystal

A quartz and bonding technology, applied in the field of bonding between quartz structures, can solve the problems of affecting the bonding effect, difficult to control the amount of glue, unable to ensure the uniformity of colloid coverage, etc., and achieve the effect of precise alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, the present invention will be further described with reference to the drawings and specific embodiments.

[0036] The present invention provides a method for bonding between quartz based on gold-tin eutectic, which can meet the problems of the prior art.

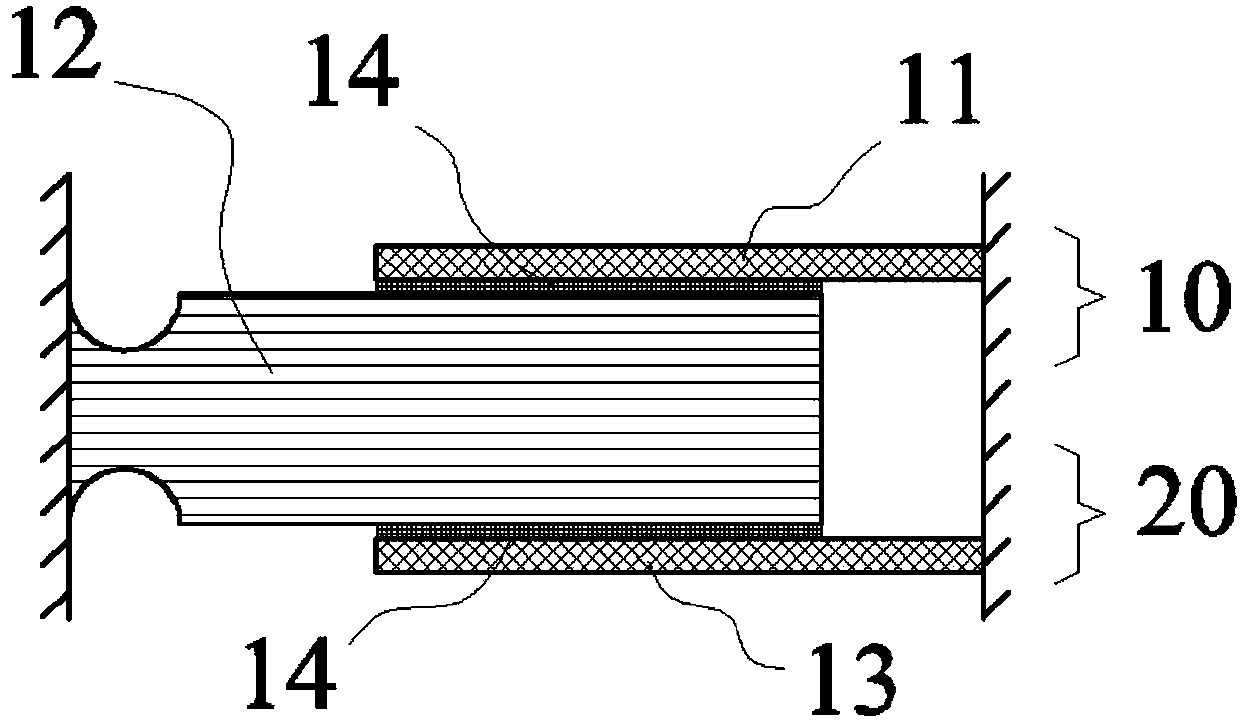

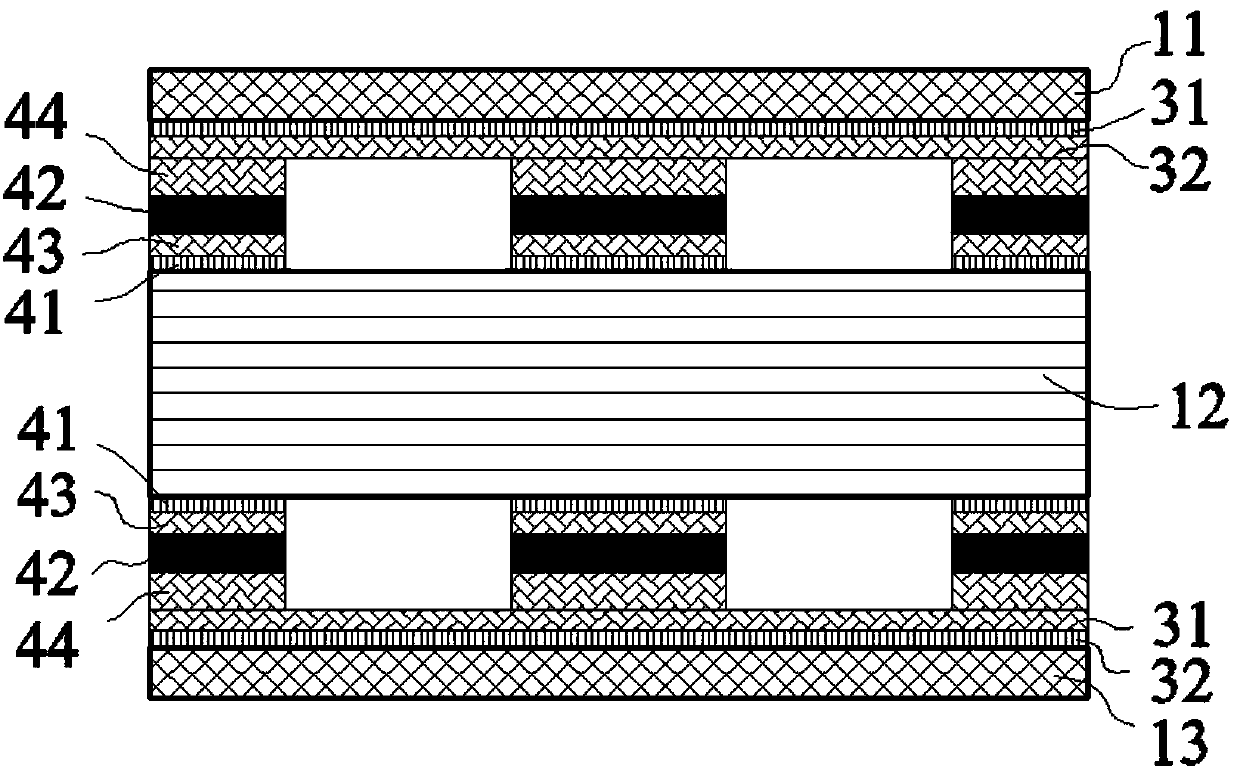

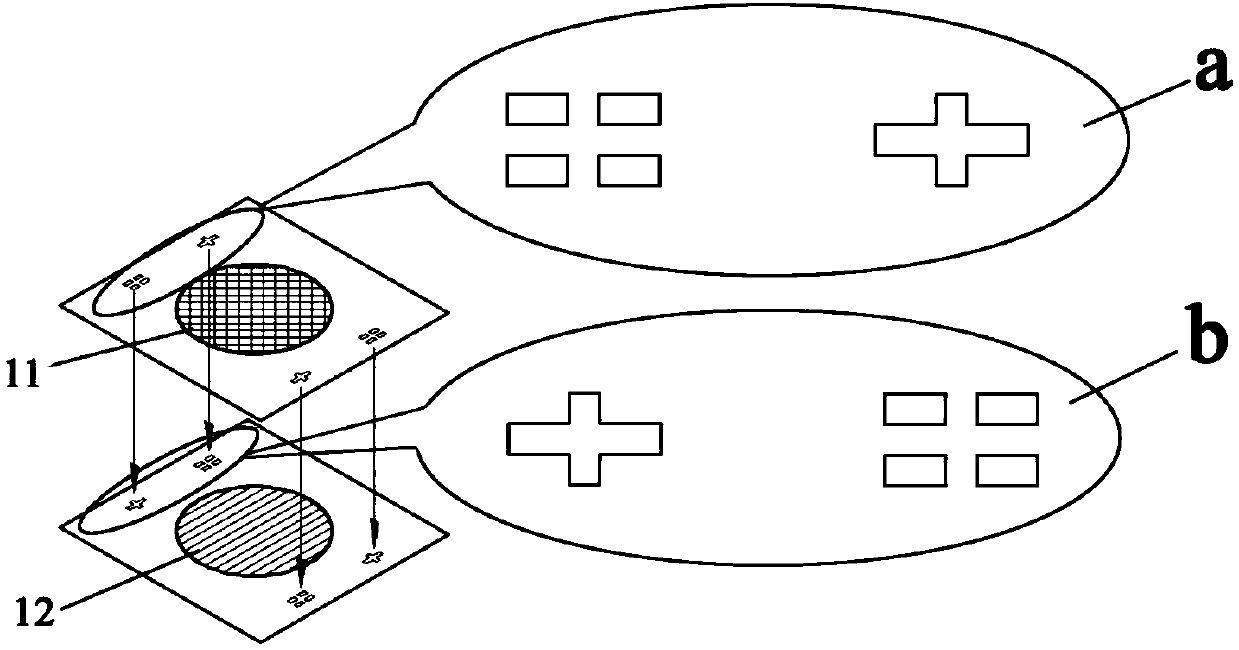

[0037] Taking the three-layer quartz sensitive structure as an example, the bonding method of the multi-layer quartz sensitive structure can be analogized. The three-layer quartz sensitive structure adopts two-by-two bonding, that is, one of the parts 11 on both sides and the middle part 12 are bonded into a pair, and then the two parts 13 on both sides are bonded on it; the bonding agent adopts The layered gold-tin eutectic solder 14, according to the principle of TLP, adopts a method of alternately depositing multiple layers of gold-tin thin films to prepare the eutectic solder layer 14.

[0038] The present invention is mainly aimed at Au-Sn-Au three-layer eutectic solder, the overall thickness of the solder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com