Nozzle system and method for removing residual stress in material through high-pressure water jet

An internal residual stress, high-pressure water jet technology, applied in heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve the problems of inability to eliminate residual stress, unfavorable to the processing process, and high manufacturing costs, achieving a wide range of applications and improving processing results. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

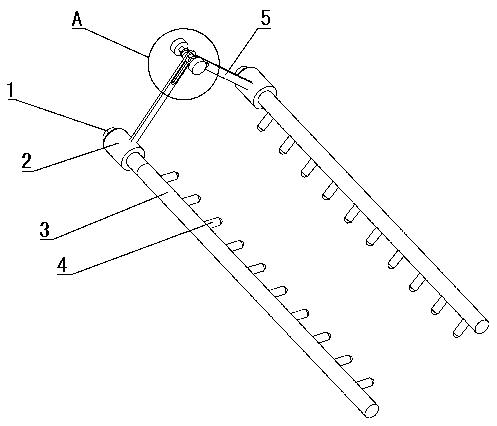

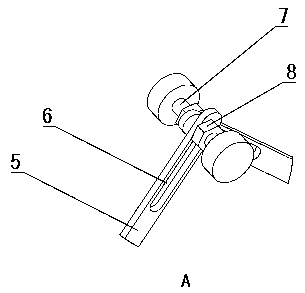

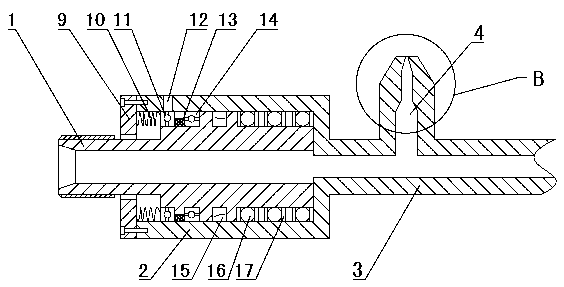

[0030] Figure 1~5 It is the best embodiment of the high-pressure water jet to eliminate the internal residual stress nozzle system of the material, and the following is combined with the attached Figure 1~5 The present invention will be further described.

[0031] refer to figure 1 , the high-pressure water jet eliminates the internal residual stress nozzle system of the material, including two spray arms 3 arranged in parallel, and a plurality of nozzles 4 are arranged at intervals on the lower side of each spray arm 3, and the nozzles 4 on the two spray arms 3 are arranged alternately The nozzle 4 on one spray arm 3 is inclined to the other spray arm 3 side, and one end of the spray arm 3 is also connected with the mandrel 1 for connecting the water supply pipeline, and the mandrel 1 is connected with the spray arm 3 in rotation. After the workpiece of the spray arm 3 walks, the water jets sprayed from the staggered nozzles 4 on the two spray arms 3 exert alternating ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com