Novel construction method of large-diameter composite structure pile consolidated foundation

A composite structure and construction method technology, which is applied in foundation structure engineering, soil protection, construction, etc., can solve the problems of limited bearing capacity of the foundation and ability to control settlement, inability to improve the soil between piles, and low requirements for bearing capacity, etc. Achieve the effects of short consolidation period, fast construction progress, and fewer piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

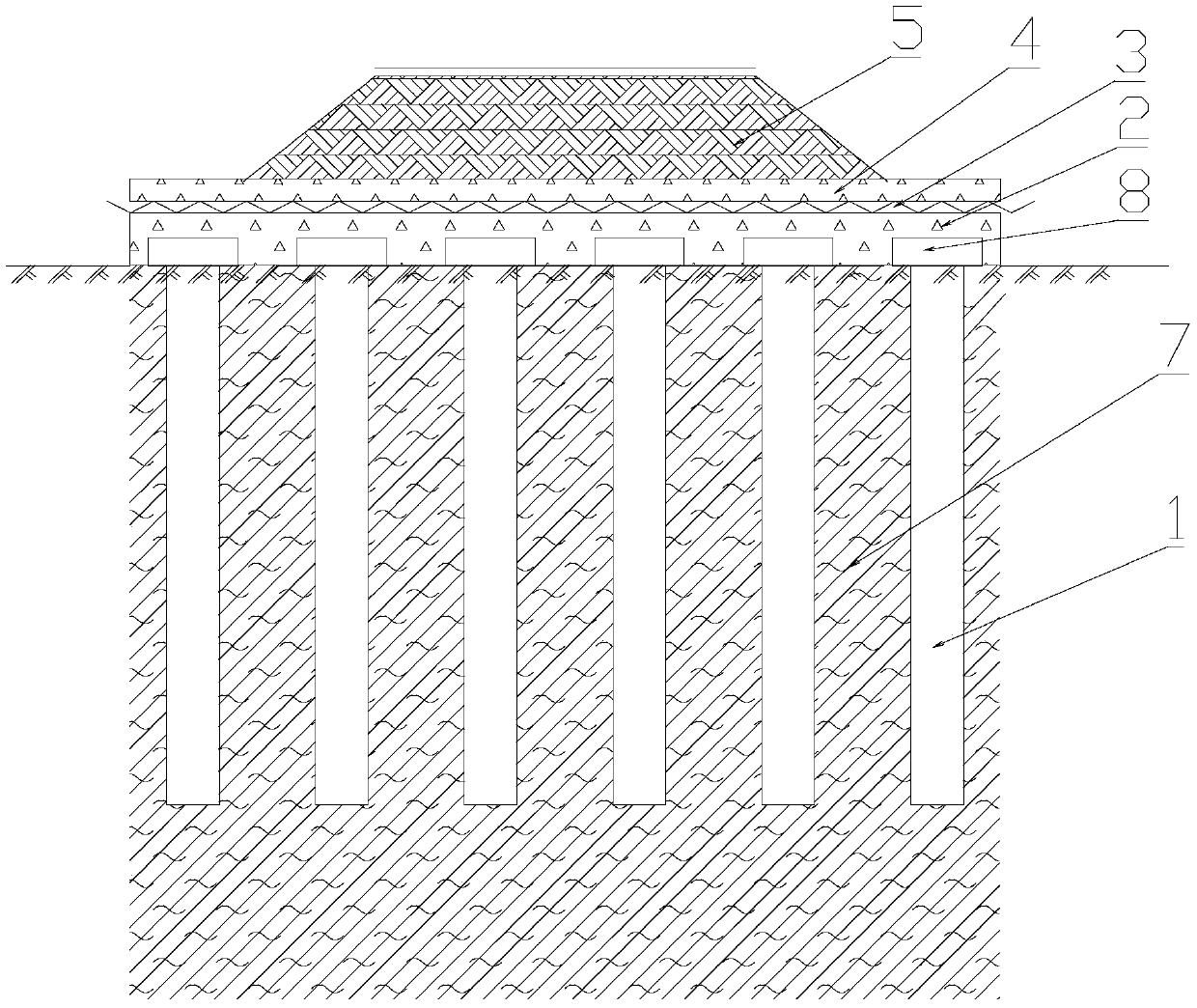

[0036] This patent is aimed at the reinforcement of deep and weak foundations under various complex conditions, especially in the absence of bearing layers or bearing interlayers, refer to figure 1 The new composite reinforced foundation formed by this construction method includes a plurality of reinforcement piles 1 vertically inserted into the weak soil layer 7, the tops of the reinforcement piles 1 protrude from the weak soil layer 7 to the outside of the ground, and the tops of the reinforcement piles 1 are provided with pile caps 8 A composite cushion is laid on the top of the pile cap 8 and its surroundings, and the subgrade 5 is filled on the top surface of the composite cushion.

[0037] The construction method of the new large-diameter composite structural pile for strengthening the foundation includes the following steps:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com