Full-automatic oil sealing type toilet bowl

An oil-sealed, fully automatic technology, applied in the field of sanitary appliances, can solve the problems of flowing noise, interference between upper and lower floors, etc., to achieve the effects of convenient use, less water consumption, and avoiding the occurrence and spread of diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

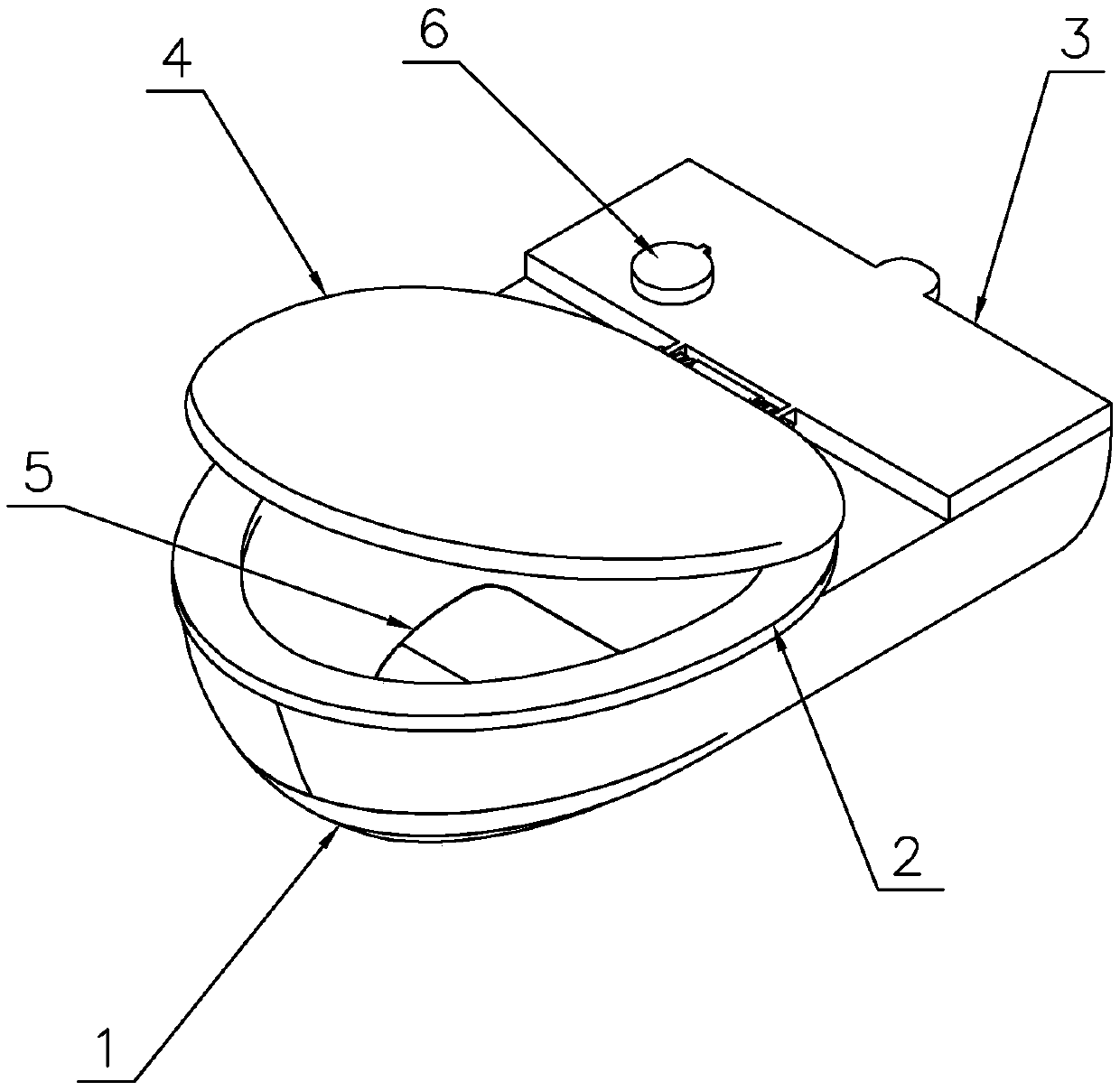

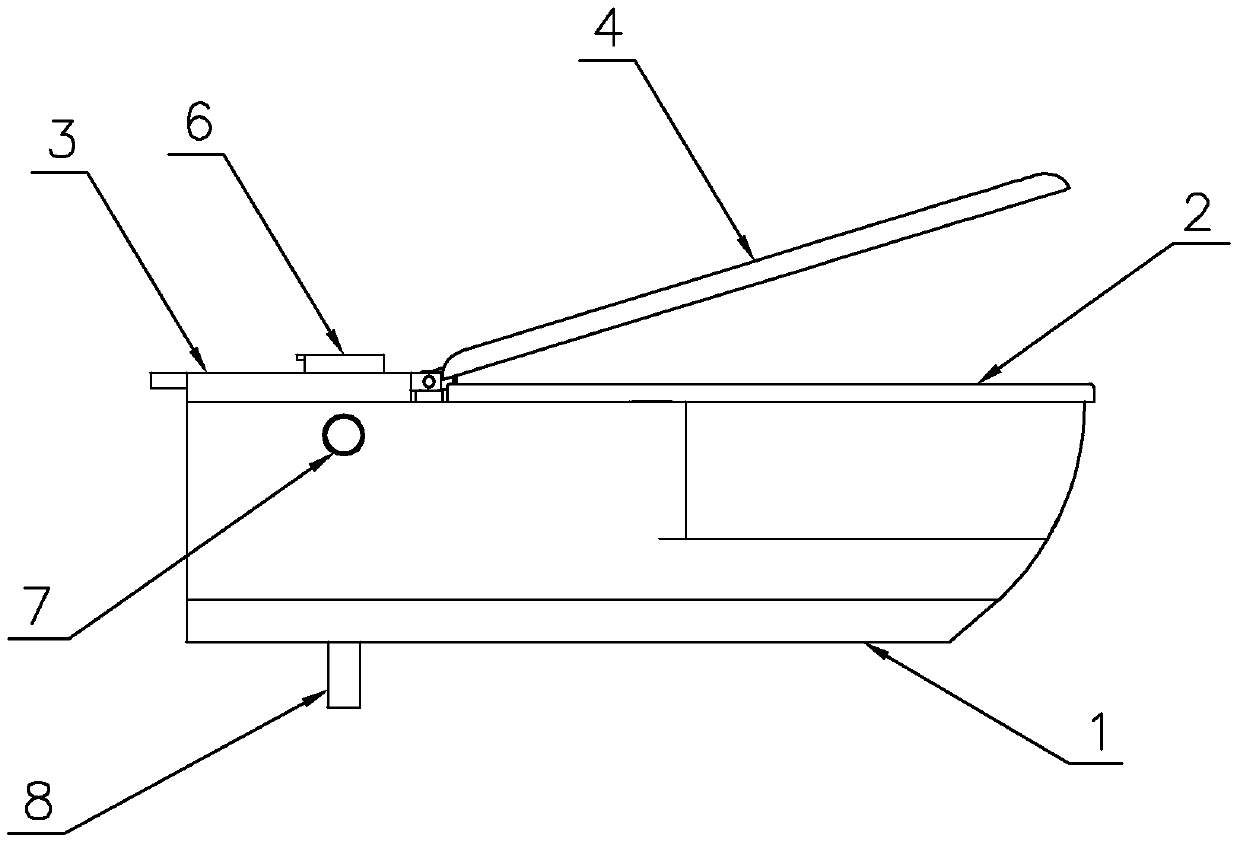

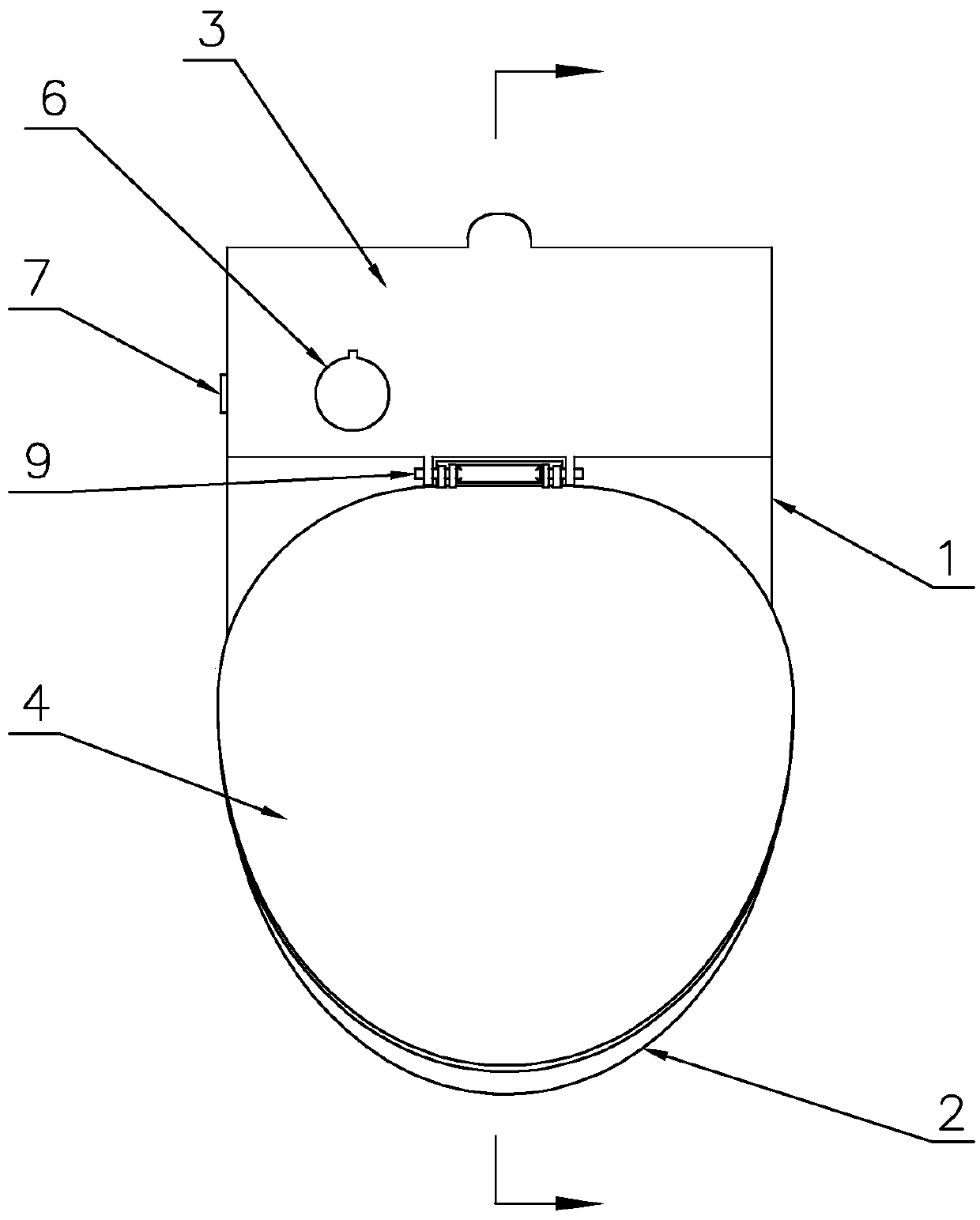

[0050] A fully automatic oil-sealed toilet, comprising a barrel body 1, a barrel cover 4, a toilet seat cushion 2, a waste discharge pipe 8, a box cover 3, a waste paper pipe 6, a first oil seal layer 13, and a waste layer 12. The barrel body 1 There is an oil seal cavity 10 and a waste storage cavity 11 inside, the oil seal cavity 10 communicates with the waste storage cavity 11 through a communication port 5, and the communication port 5 is located at the bottom of the oil seal cavity 10 for connecting the oil seal cavity 10 and the waste storage cavity 11 ; The waste storage chamber 11 is provided with a waste discharge pipe 8, one end port of the waste discharge pipe 8 is located in the waste storage chamber 11, and the other end is located outside the barrel body 1, and is connected to the sewer installed in the toilet; the oil seal chamber 10 and the waste storage chamber 11 are provided with a waste layer 12, and a first oil seal layer 13 is provided above the waste laye...

Embodiment 2

[0052] The difference of the toilet as in embodiment 1 is:

[0053] The first oil sealing layer contains a grease composition, and the grease composition is composed of rapeseed oil. The thickness of the first oil sealing layer is 10cm.

Embodiment 3

[0055] The difference of the toilet as in embodiment 1 is:

[0056] Described first oil sealing layer contains fat composition and stearic acid, and by weight percentage, described fat composition is made up of 50% palm oil, 20% soybean oil and 30% rapeseed oil; The consumption of described stearic acid 15% of the weight of the oil composition. The thickness of the first oil sealing layer is 6cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com