Large-scale wind power blade with multi-beam structure and manufacturing method thereof

A large-scale technology for wind power blades, applied in wind power generation, wind engines at right angles to the wind direction, wind engines in line with the wind direction, etc., can solve the problems of structural safety and high cost, achieve strength safety, reduce blade quality, Effect of increasing ply thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments of the specification.

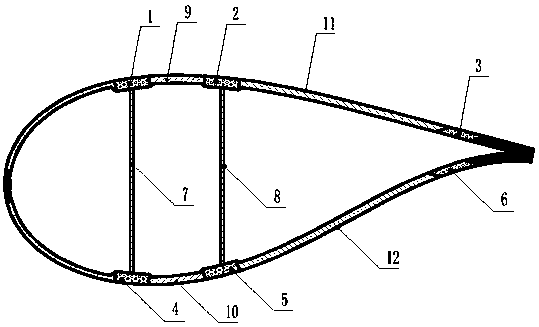

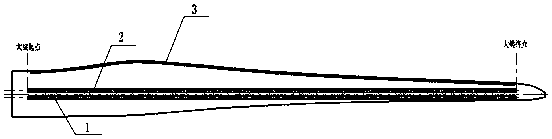

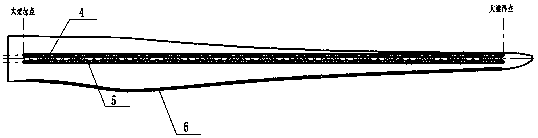

[0031] figure 1 It is a schematic cross-sectional view of the structure of the blade shell in this embodiment, figure 2 , image 3 It is a schematic diagram of the distribution of the blade shell structure along the span direction.

[0032] It can be seen from the accompanying drawings that the present invention provides a large-size wind power blade with multi-beam structure, which adopts a hollow layout structure, including blade skin suction side (11), blade skin pressure side (12), main load-bearing structure girder (1, 2, 4, 5), shear web (7, 8), trailing edge load-bearing structural trabecular (3, 6). The main load-bearing structure girders (1, 2, 4, 5) are divided into four blade structure girders. The width of the blade structure girders in this implementation is 0.31m, and the total length of the girders is 52.51m. °Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface density | aaaaa | aaaaa |

| surface density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com