Piston bracket retractable single-section rubber membrane sealed dry gas holder

A rubber membrane, single-stage technology, used in the field of gas cabinets, can solve the problems of affecting the rise of the piston, failure of the rubber membrane, and many consumables, etc., and achieve the effect of saving steel and reducing the height of the cabinet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

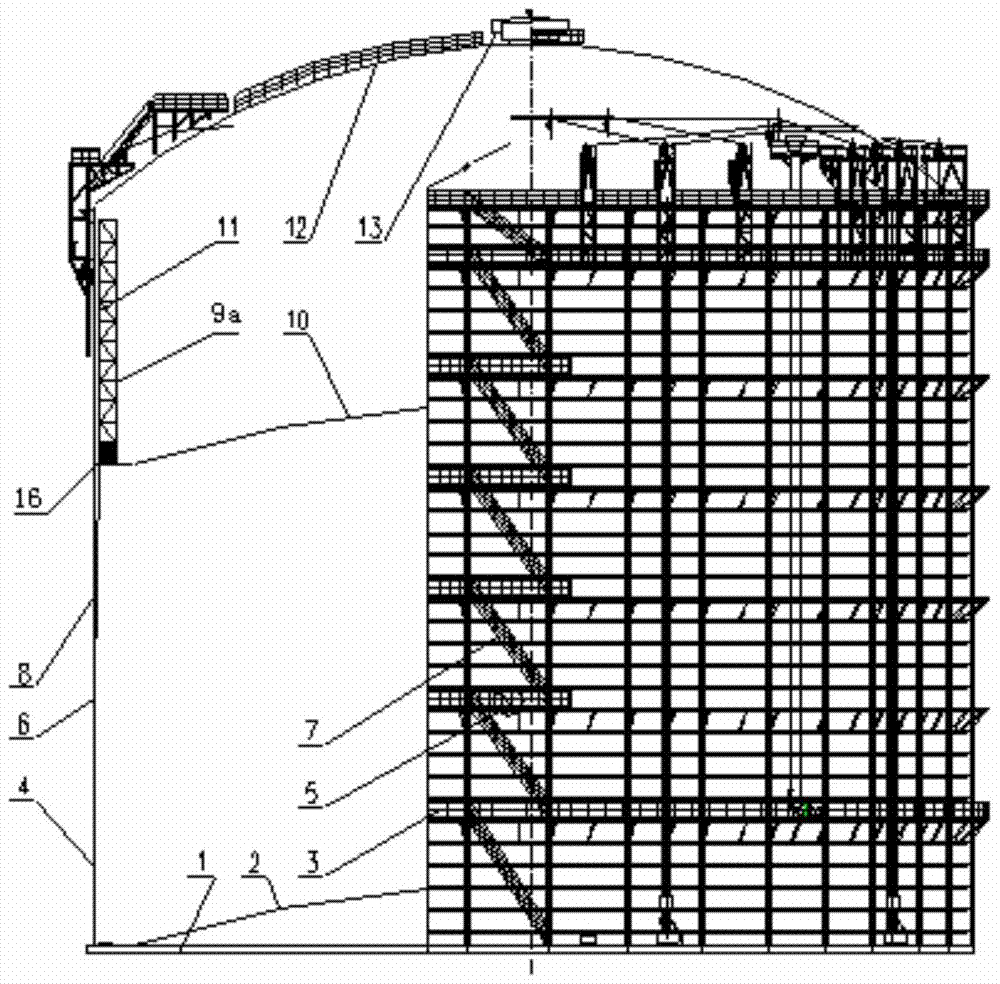

[0030] figure 1 It is a schematic diagram of an existing single-section rubber membrane-sealed dry-type gas cabinet. This type of gas cabinet consists of a cabinet body (including a cabinet bottom plate 2, a side plate 4, and a cabinet top plate 12) and a piston 16. The piston 16 is supported by a piston bracket. 9a drives up and down movement, and the bottom of piston 16 is fixed with piston plate 10, and in the operation process of gas holder, realizes the entry and exit of gas by moving up and down of piston 16.

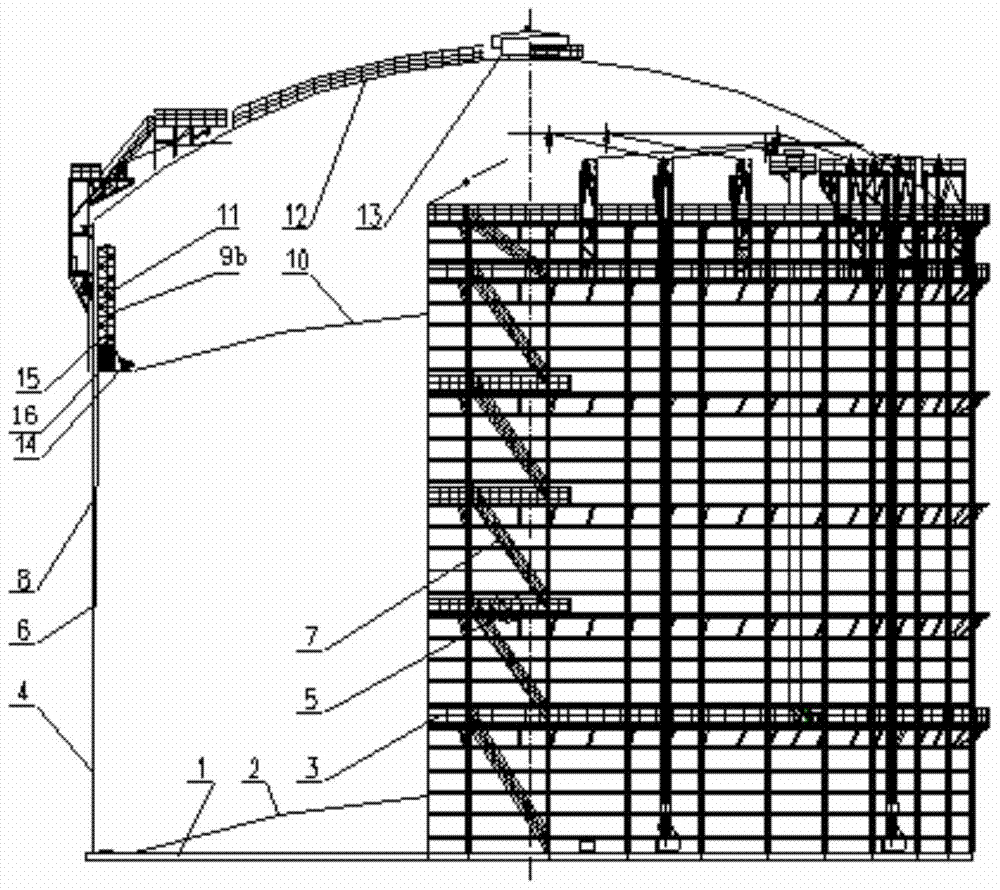

[0031] Such as figure 2 As shown, a single-stage rubber-membrane-sealed dry-type gas cabinet with a retractable piston bracket includes a cabinet body (including a cabinet bottom plate 2, a side plate 4, and a cabinet top plate 12), a piston 16, and a piston bracket that drives the piston 16 to move up and down. 9b, the piston plate 10 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com