Passive temperature test system for key point of primary equipment in substation

A technology of primary equipment and testing system, which is applied in the field of power system, can solve problems such as being easily affected by sunlight, easy to miss details, expensive equipment, etc., and achieve the effects of saving manpower, improving maintenance quality, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

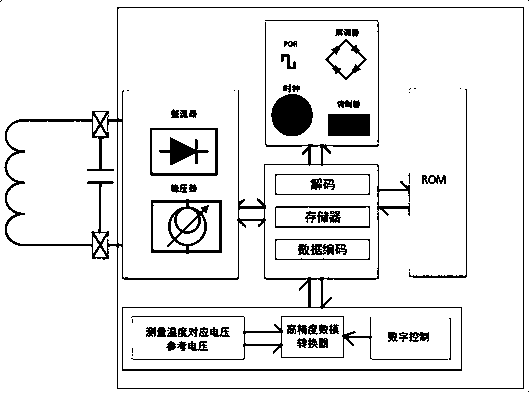

[0023] (1) Development of passive wireless temperature sensor

[0024] The temperature sensor uses the characteristics of temperature-sensitive materials and physical parameters of electronic components that change with temperature to convert non-electrical temperature parameters into electrical quantities, so that precise temperature measurement and automatic control can be performed. The temperature sensor is integrated into the RFID tag chip, which can detect the temperature of the surrounding environment while realizing automatic identification, which greatly expands the application of RFID technology.

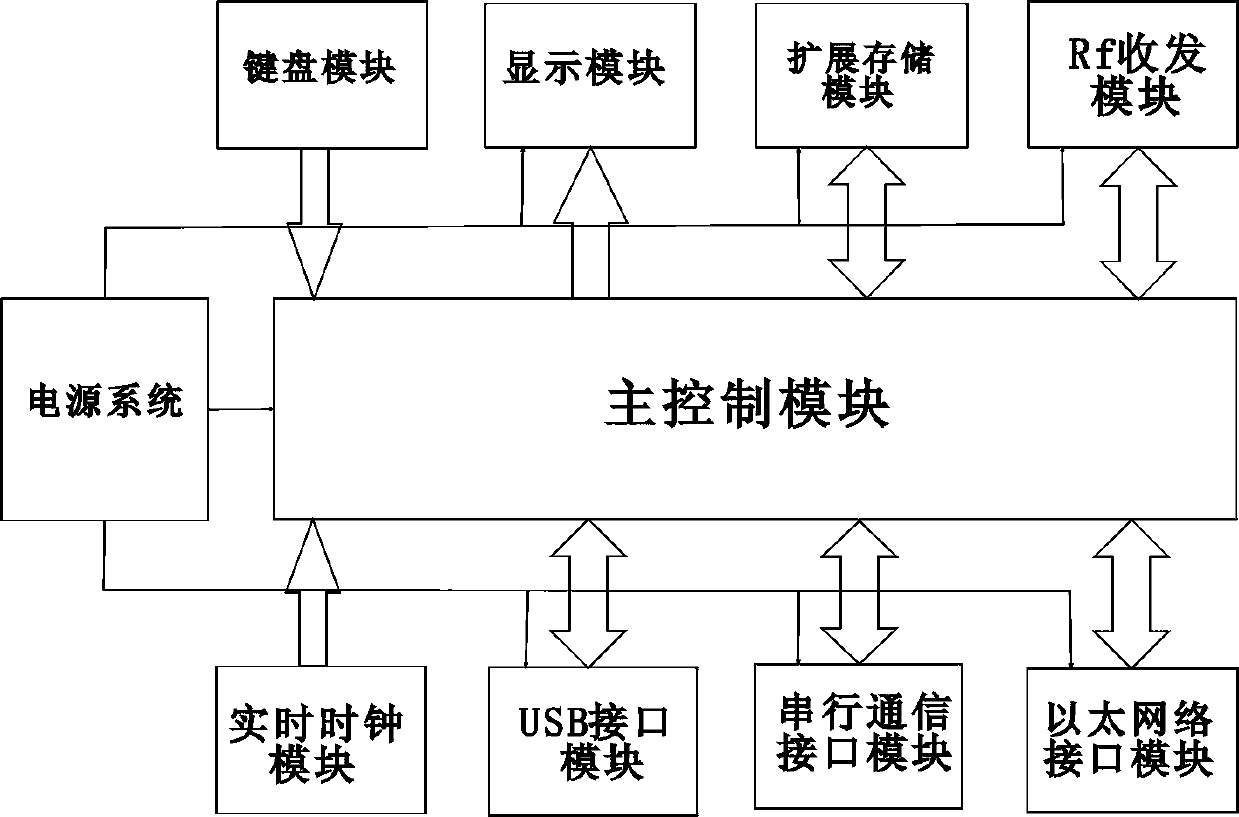

[0025] In the present invention, the traditional UHF-RFID electronic tag is added to the temperature sensing module, and at the same time an A / D converter is added to convert the signal value of the temperature sensing module into a digital signal, and it is in accordance with the standard ISO18000-6 and EPCClassGen2 communication protocol , transmitted to the online reade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com