Graphene capacitive touch screen with pressure induction function

A capacitive touch screen and graphene technology, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve problems such as difficult to support touch parameter perception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

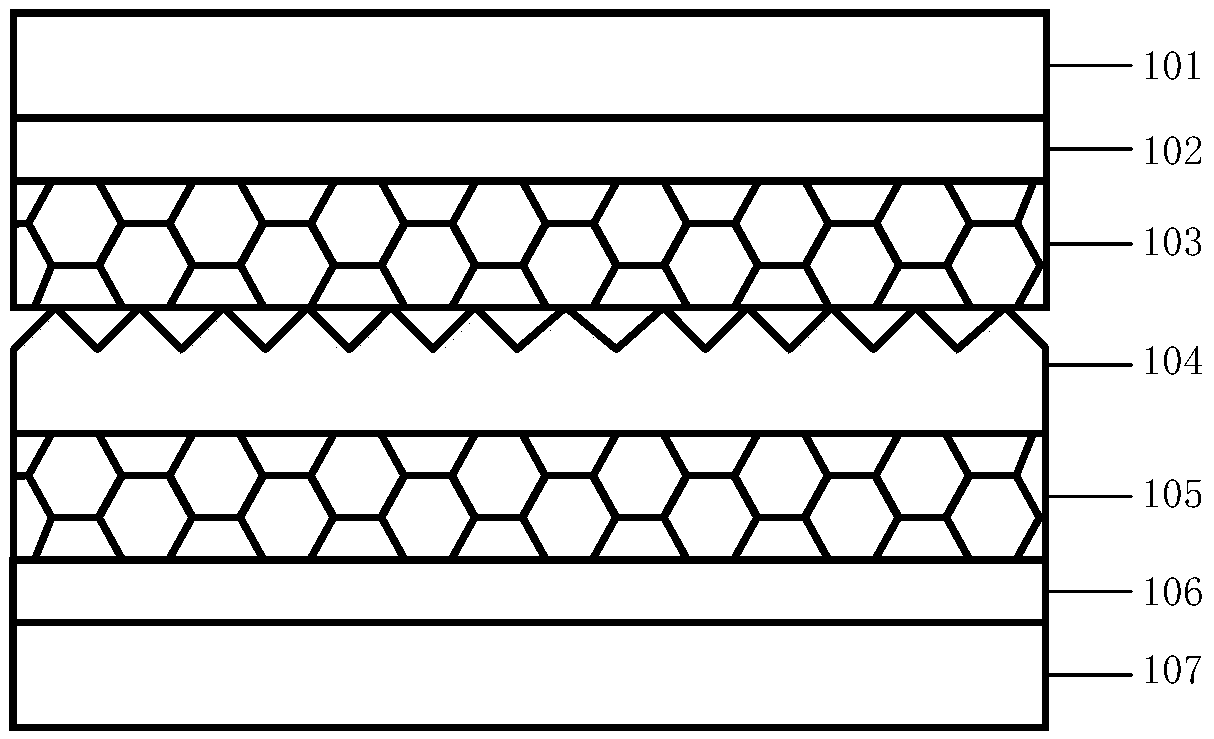

[0017] The device structure of the pressure-sensitive graphene capacitive touch screen of the present embodiment is as follows figure 1 As shown, the upper graphene transparent conductive film layer 103 and the lower graphene transparent conductive film layer 104 are all made of CVD growth graphene, and are transferred to the flexible PET substrate by a large area transfer method, and the number of layers of the graphene is 1 layer, the square resistance is 200Ω / sq, and the light transmittance range is 91%.

[0018] In this embodiment, the patterning of the graphene transparent conductive film is realized by photolithography and etching.

[0019] In this embodiment, the graphene capacitive touch screen also includes a pressure-sensitive polymer elastomer 104, and the upper graphene transparent conductive film layer 103 and the lower graphene transparent conductive film layer 105 are respectively positioned on the pressure-sensitive polymer elastomer. 104 upper and lower surfa...

Embodiment 2

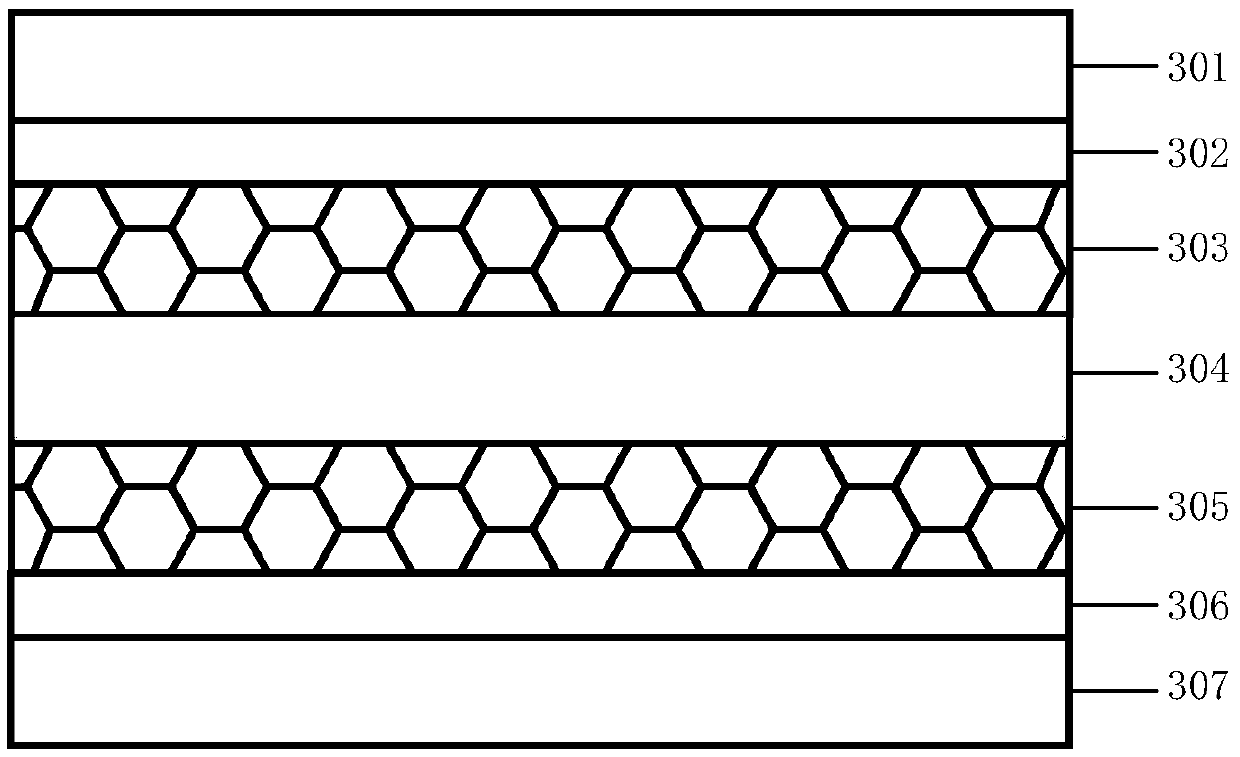

[0028] The device structure of the pressure-sensitive graphene capacitive touch screen of the present embodiment is as follows image 3 As shown, the upper graphene transparent conductive film layer 303 and the lower graphene transparent conductive film layer 304 are all made of CVD grown graphene, and transferred to the flexible PI substrate by a large area transfer method, the graphene layer The number is 3 layers, the square resistance is 100Ω / sq, and the light transmittance range is 85%.

[0029] In this embodiment, the graphene capacitive touch screen also includes a pressure-sensitive polymer elastomer 304, and the upper graphene transparent conductive film layer 303 and the lower graphene transparent conductive film layer 305 are located on the pressure-sensitive polymer elastomer respectively. 304 upper and lower surfaces.

[0030] In this embodiment, the pressure-sensitive polymer elastomer 304 is made of TPU material with a thickness of 200 um, and the surface is no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com