Ultra wideband material microwave absorber loaded with chip resistor

A technology of ultra-broadband and absorber, which is applied in the field of ultra-broadband metamaterial microwave absorber, which can solve the problems of complex preparation process, unfavorable engineering application, and limited broadening range of strong absorption band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

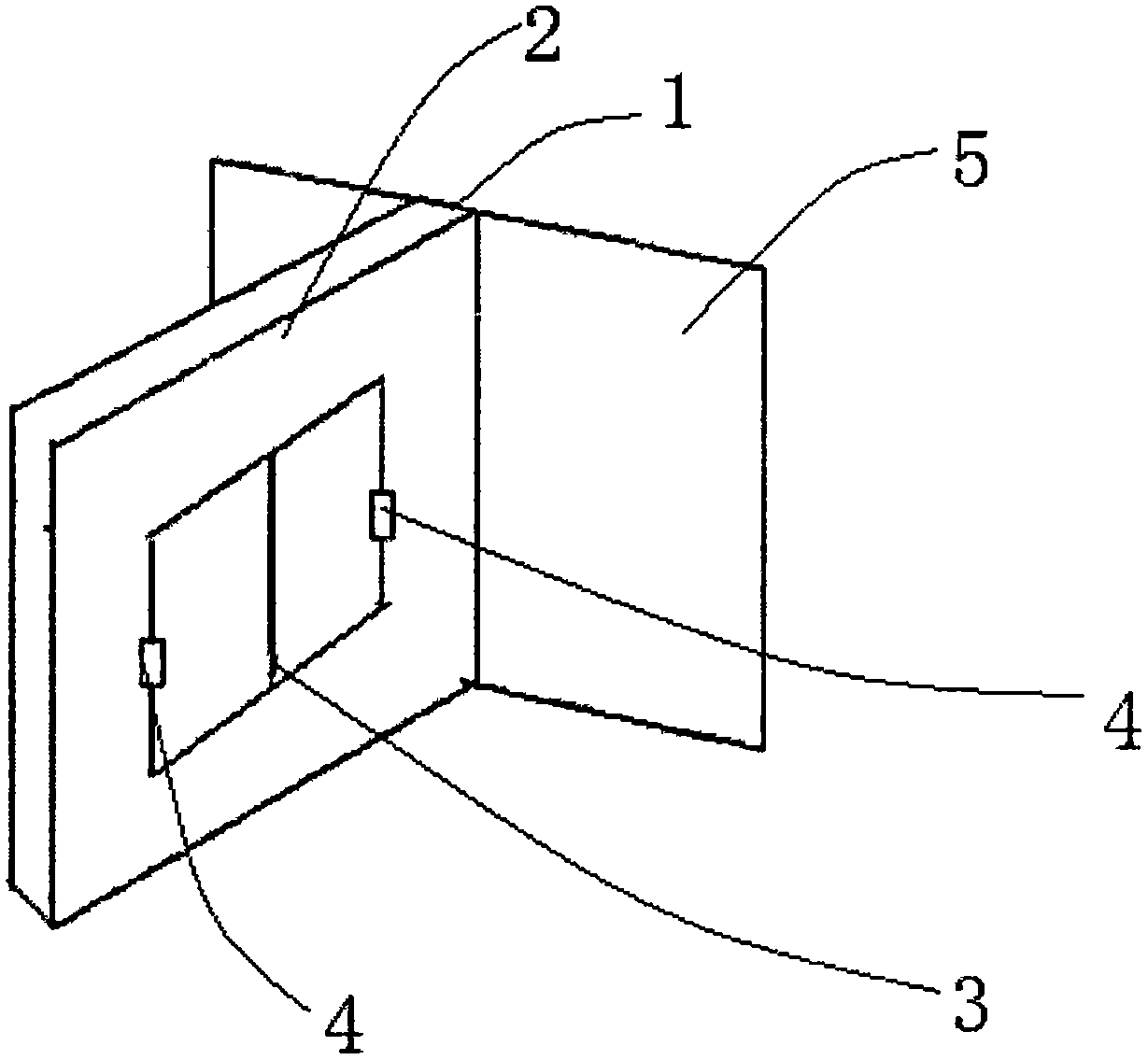

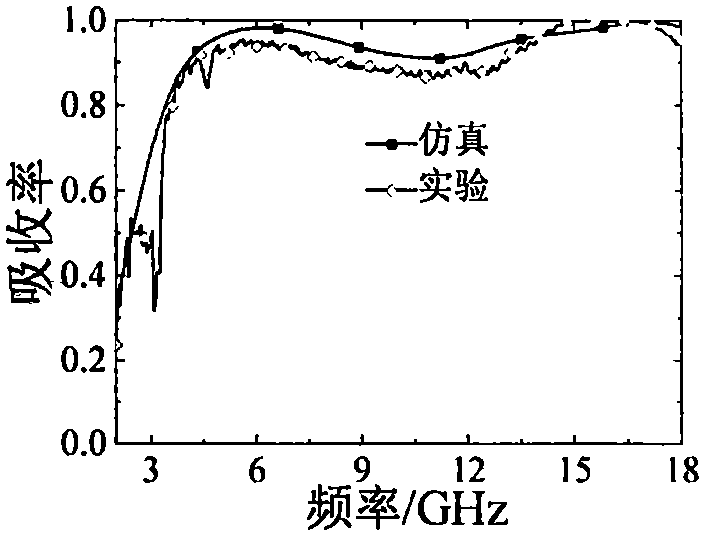

[0033] Example 1, such as figure 1 and Figure 2a and Figure 2b As shown, the absorber consists of a dielectric substrate 2, a metal slotted ring structure 3 (square metal slotted ring resonator structure) etched on the substrate, a chip resistor 4 embedded in the metal slotted ring structure 3, and a metal back Plate 5 is constructed from figure 1 The period length of the middle unit structure 1 is px and the width is py, the length of the dielectric substrate 2 is px, the width is h and the thickness is ts, the metal slotted ring structure 3 has a long side, a wide side b, a line width of w, and a slit width is g, and the resistance welded at the opening of the metal slit ring is R 1 and R 2. By changing the geometric parameters of the unit structure 1, it can work in different frequency ranges. Variation range of geometric parameters of unit structure 1:

[0034] Unit structure cycle length px width py: 5mm~50mm;

[0035] Dielectric substrate length px: 5mm~50mm; ...

Embodiment 2

[0049] Example 2, such as image 3 and Figure 4 As shown, the absorber consists of a dielectric substrate 2, a metal slotted ring structure 3 etched on the substrate (square metal double slotted ring resonator structure), a chip resistor 4 embedded in the metal slotted ring structure 3, and a metal back Plate 5 is formed, wherein, the period length of the unit structure is px and the width is py, the length of the dielectric base substrate is px, the width is h and the thickness is ts, the length of the slit ring structure is a, the broad side is b, the line width is w, and the slit width is g, the resistance welded at the opening of the slit ring is R 1 and R 2 . By changing the geometric parameters of the unit structure, it can work in different frequency ranges. The variation range of the geometric parameters of the unit structure:

[0050] Unit structure cycle length px width py: 5mm~50mm;

[0051] Dielectric substrate length px: 5mm~50mm;

[0052] Dielectric subst...

Embodiment 3

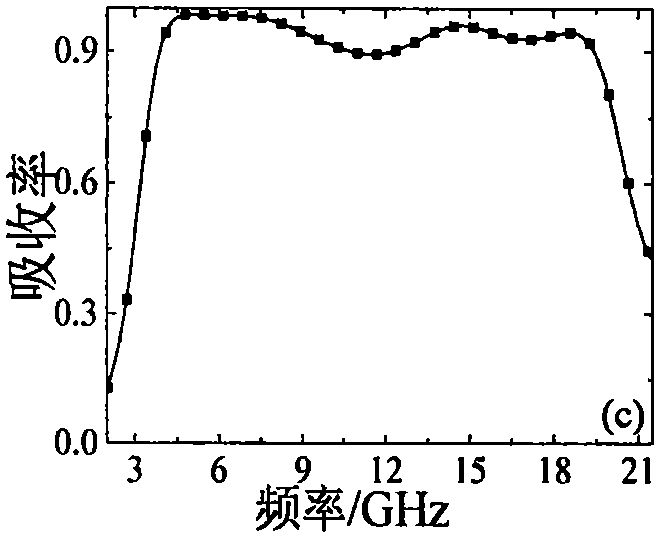

[0065] Example 3, such as Figure 5 and Figure 6 As shown, the absorber consists of a dielectric substrate 2, a metal slotted ring structure 3 etched on the substrate (circular single slotted ring resonator structure), a chip resistor 4 embedded in the metal slotted ring structure 3, and a metal The backplane is composed of 5, wherein the unit structure period length is px and the width is py, the length of the dielectric base substrate is px, the width is h and the thickness is ts, the outer ring radius of the circular slotted ring structure is r, the line width is w, and the slit width is g, the resistance welded at the opening of the slit ring is R. By changing the geometric parameters of the unit structure, it can work in different frequency ranges. The variation range of the geometric parameters of the unit structure:

[0066] Unit structure cycle length px width py: 5mm~50mm;

[0067] Dielectric substrate length px: 5mm~50mm;

[0068] Dielectric substrate width h: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com