CKDY electro-hydraulic execution advanced motor control algorithm

A motor control, electro-hydraulic execution technology, applied in motor generator control, electronic commutation motor control, control system, etc., to achieve the effect of reducing current consumption, stable operation, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

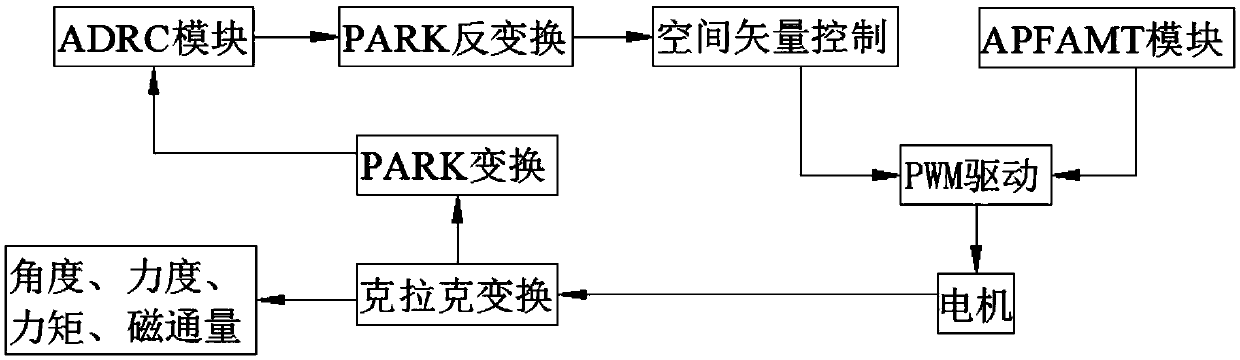

[0019] Such as figure 1 As shown, a CKDY electro-hydraulic implementation of an advanced motor control algorithm is characterized in that it includes the following steps:

[0020] Step 1: After the AC rectification, the voltage is matched with the power of the APFAMT module to obtain a stable voltage as the bus voltage of the motor;

[0021] Step 2: Generate a 20KHz interrupt, and sample the bus voltage Vbus, bus current Ibus, phase voltage Vu, Vv, Vw, phase current Iu, Iv, Iw in the interrupt;

[0022] Step 3: Perform Clarke transformation on the phase voltages Vu, Vv, and Vw in step 2 to obtain...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap