Method and device for controlling the speed of a motor

A technology of motor speed and control method, applied in the direction of motor control, motor generator control, control of electromechanical transmission devices, etc., can solve problems affecting motor performance, motor speed fluctuation, etc., and achieve the effect of stable motor operation and meeting noise requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

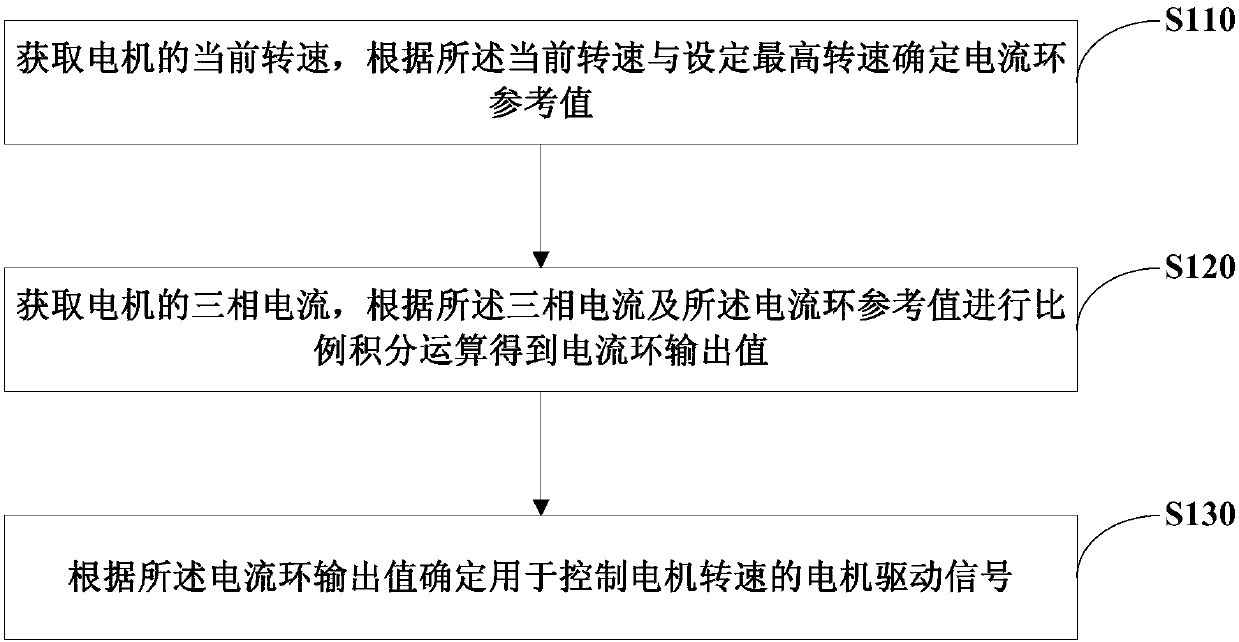

[0022] figure 1 It is a flowchart of a motor speed control method provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation where the motor automatically adjusts the speed when the external wind pressure changes. This method can be executed by the motor speed control device. Specifically include the following steps:

[0023] Step 110, obtaining the current rotation speed of the motor, and determining a current loop reference value according to the current rotation speed and the set maximum rotation speed.

[0024] Among them, the motor speed is the angular velocity of the motor rotor. The current rotational speed is the angular velocity of the motor rotor at the sampling moment. Preferably, acquiring the current rotational speed of the motor includes acquiring a current angle of the motor rotor, and determining the current rotational speed according to the current angle. The interval of the rotor and the corresponding angle during the...

Embodiment 2

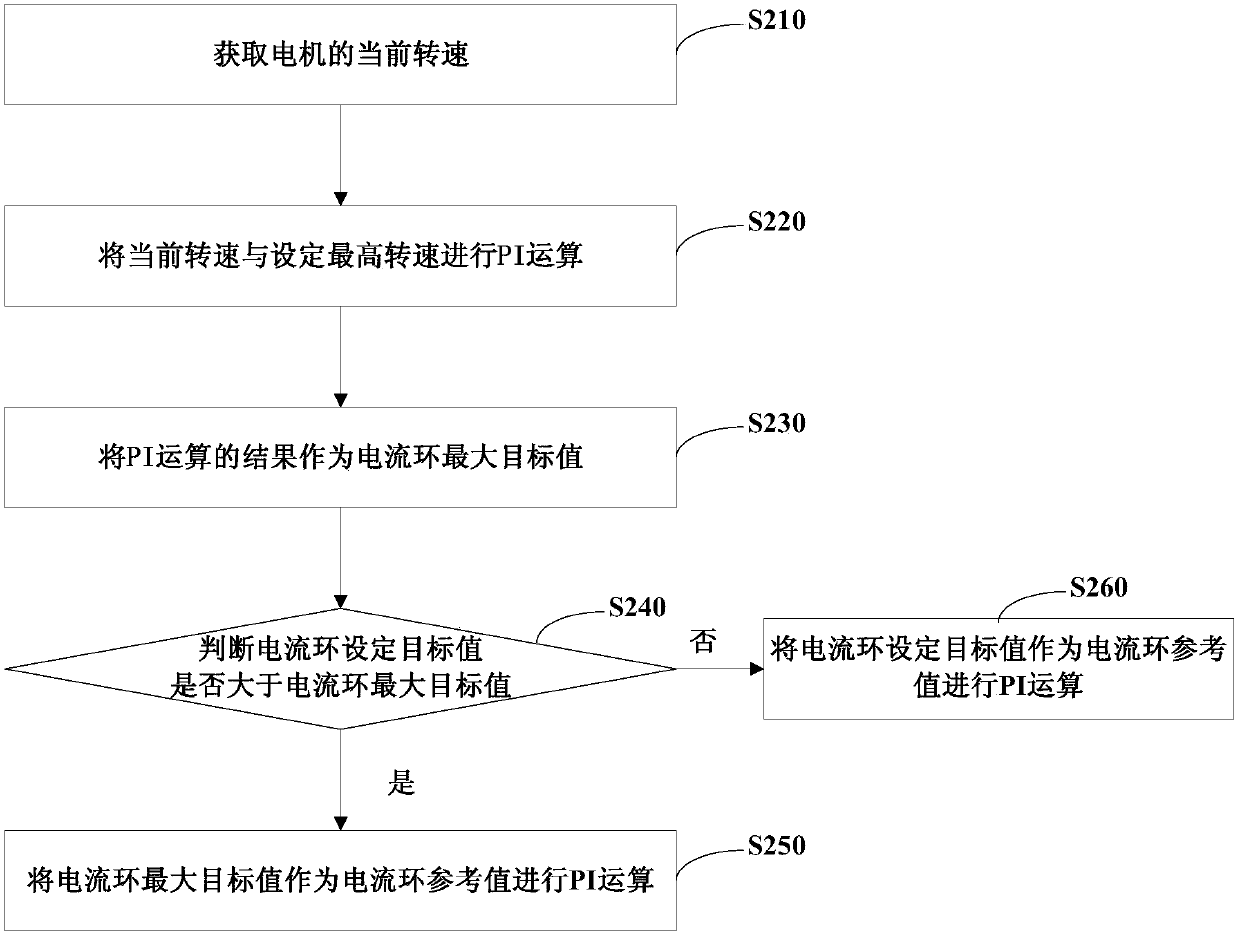

[0032] Figure 2a It is a flow chart of the rotation speed protection step in the motor rotation speed control method in the second embodiment of the present invention. On the basis of the above-mentioned embodiments, the technical solution of this embodiment further defines the method of determining the reference value of the current loop according to the current speed and the set maximum speed, which specifically includes the following steps:

[0033] Step 210, acquiring the current rotational speed of the motor.

[0034]Fix the Hall sensor on the silicon steel sheet of the stator core and electrically connect it with the motor controller. The motor controller can determine the interval of the rotor and the corresponding angle during the operation of the motor through the Hall sensor, so as to obtain an ideal electrical angle at the Hall position. For example, the motor controller determines through the Hall sensor that the rotor is currently in the range of 60°-120°, and ...

Embodiment 3

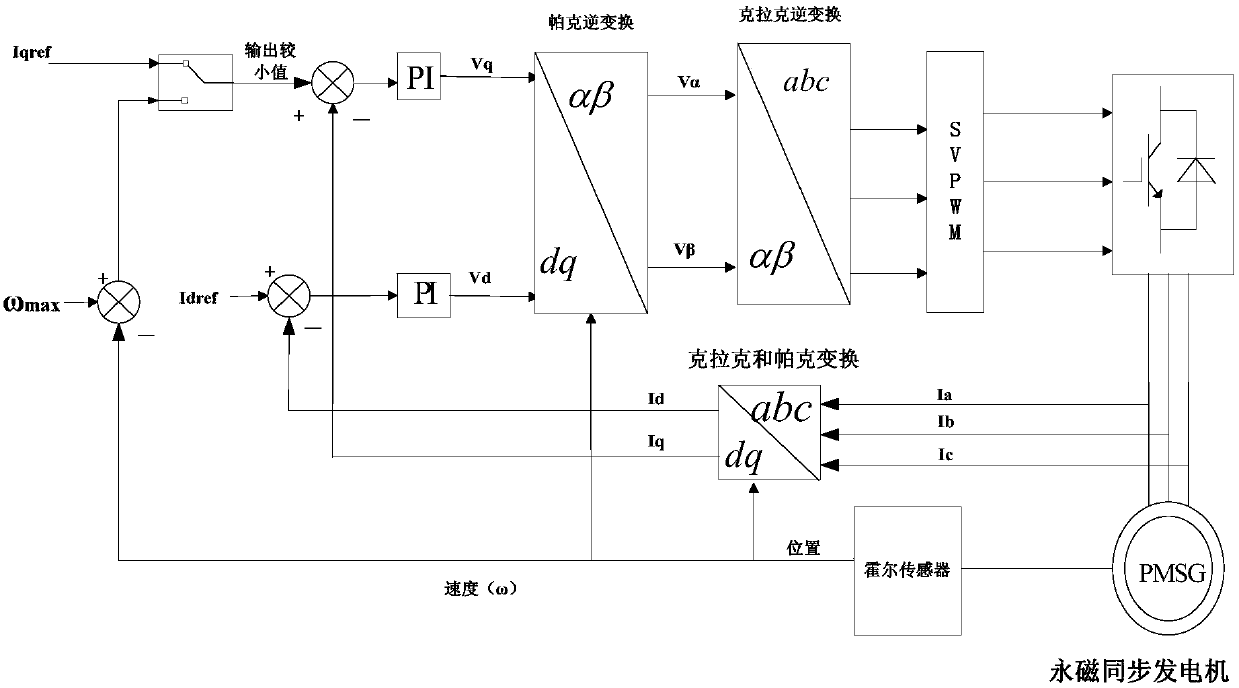

[0047] Figure 3a It is a flow chart of the rotation speed protection step in the motor rotation speed control method in the third embodiment of the present invention. On the basis of the above-mentioned embodiments, the technical solution of this embodiment further defines the determination of the current loop reference value according to the current speed and the set maximum speed, which specifically includes the following steps:

[0048] Step 310, acquiring the current rotational speed of the motor.

[0049] The interval of the rotor and the corresponding angle during the operation of the motor can be determined through the Hall sensor, so as to obtain an ideal electrical angle at the Hall position. The specific calculation process is the same as the above embodiment, and will not be repeated here.

[0050] Step 320 , judging whether the current rotation speed is greater than the set maximum rotation speed, if yes, execute step 330 , if not, execute step 310 .

[0051] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com