Electronic device and radiating casing thereof

A casing and electronic component technology, applied in the field of electronic devices and their heat dissipation casings, can solve the problems of large volume and thickness, which cannot meet the needs of ultra-thin electronic products, so as to save space, meet the needs of ultra-thin, high The effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

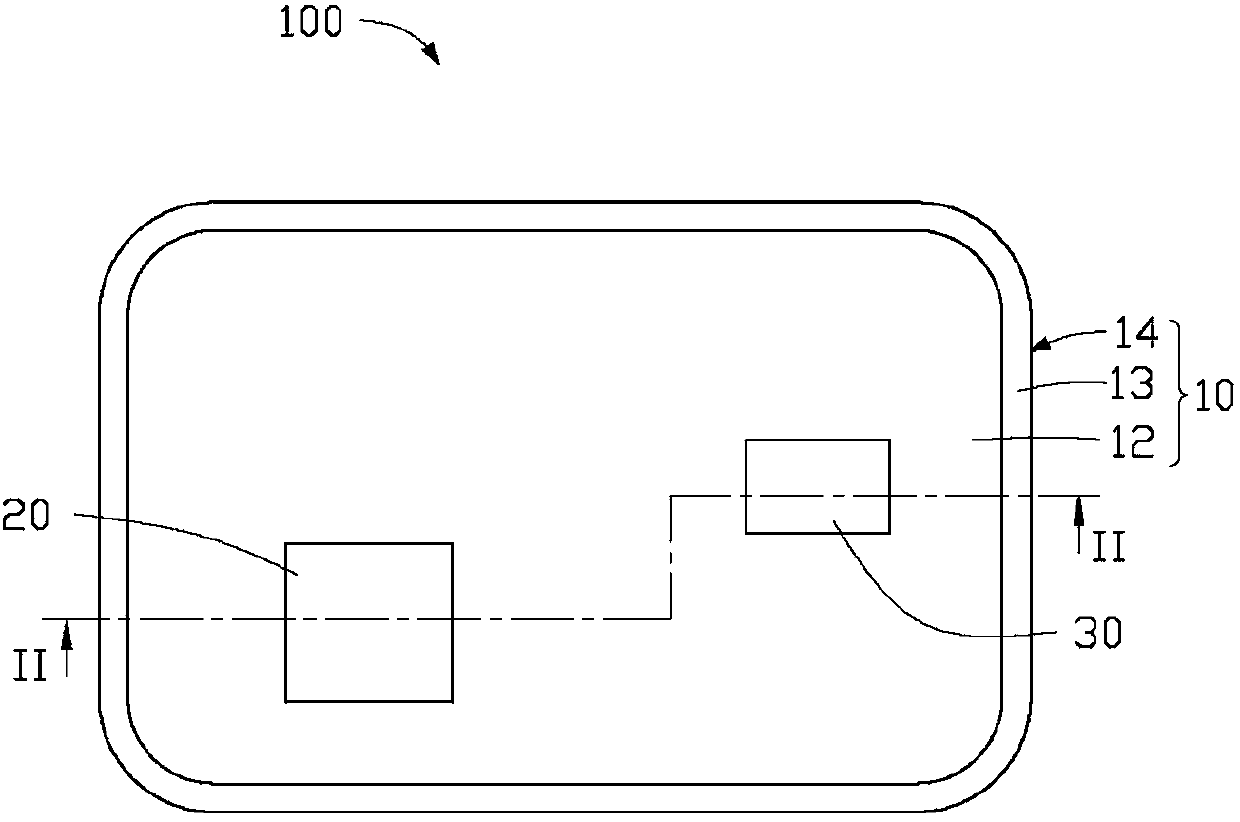

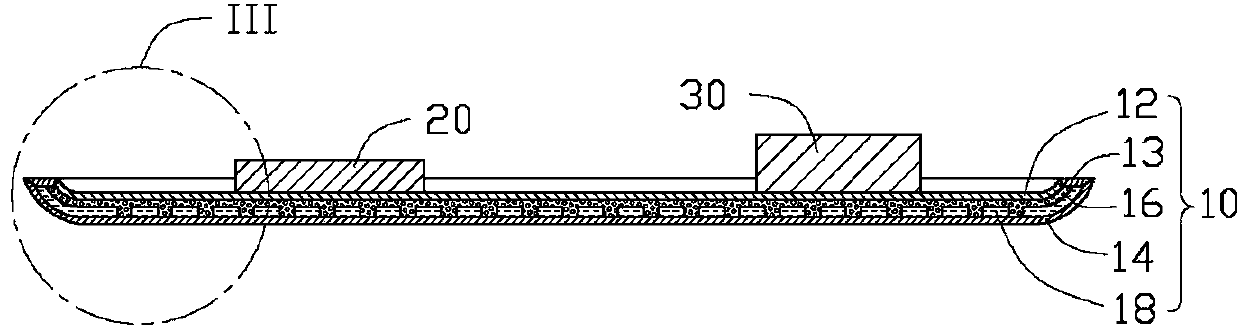

[0016] Please refer to Figure 1 to Figure 3 The electronic device 100 according to the first embodiment of the present invention includes a heat dissipation case 10 and two heat generating electronic components 20 , 30 combined with the heat dissipation case 10 through heat conduction.

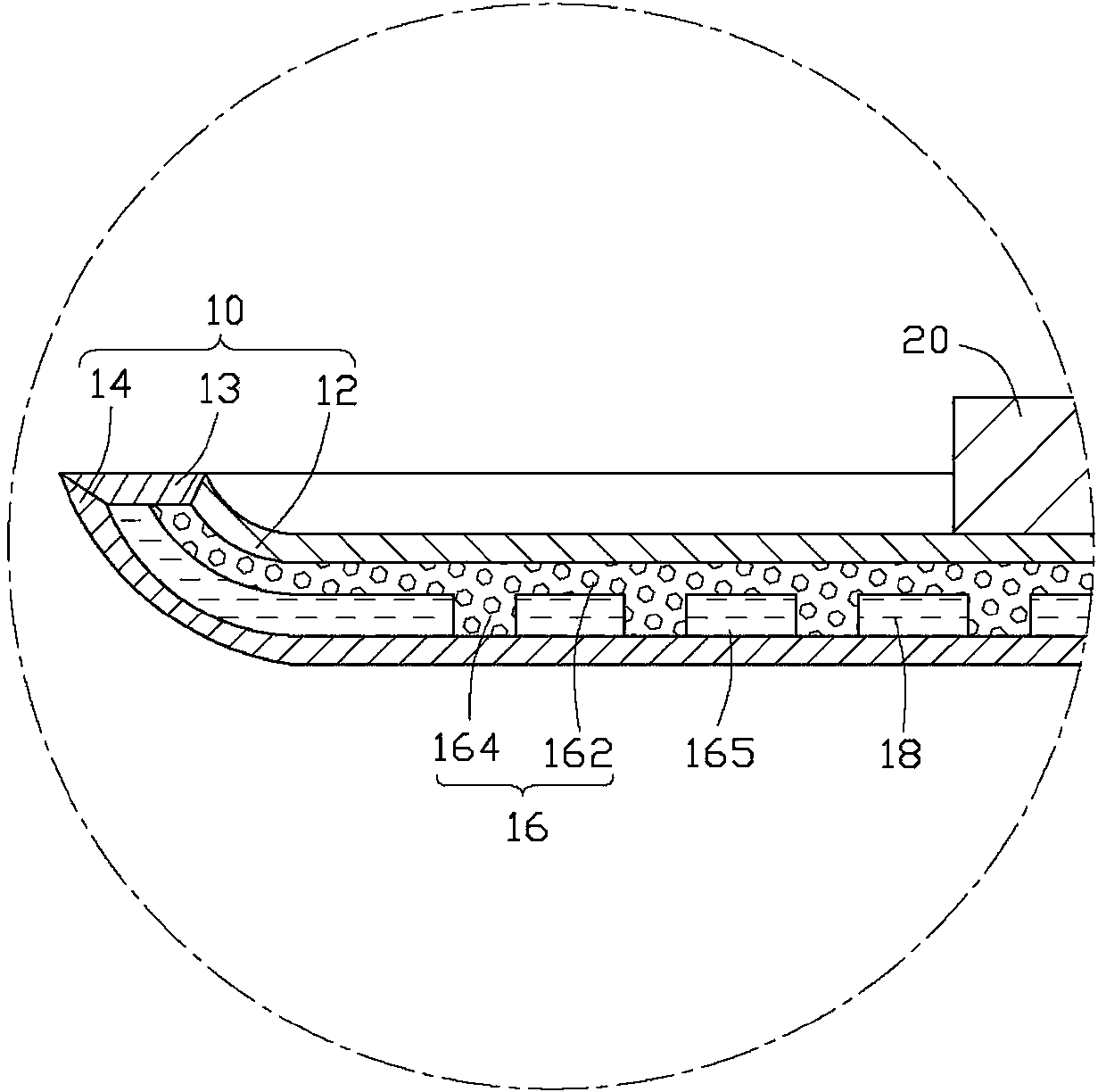

[0017] The cooling case 10 includes a top plate 12 , a bottom plate 14 , a pore structure 16 and a working medium 18 between the top plate 12 and the bottom plate 14 .

[0018] The materials of the top plate 12 and the bottom plate 14 can be copper, aluminum, titanium, nickel and other metal materials with good thermal conductivity. The top board 12 is located inside the electronic device 100 , and the bottom board 14 is located outside the electronic device 100 . The opposite ends of the top board 12 and the bottom board 14 are raised upwards, and the cross-sections of the raised two ends are arc-shaped. An outer edge of the top plate 12 is connected to an outer edge of the bottom plate 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com