Buried oil-water separator

A technology of oil-water separator and oil-water separation, which is applied in the field of sewage treatment and buried oil-water separator to achieve the effect of improving work efficiency, reducing manual inspection, and reducing occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

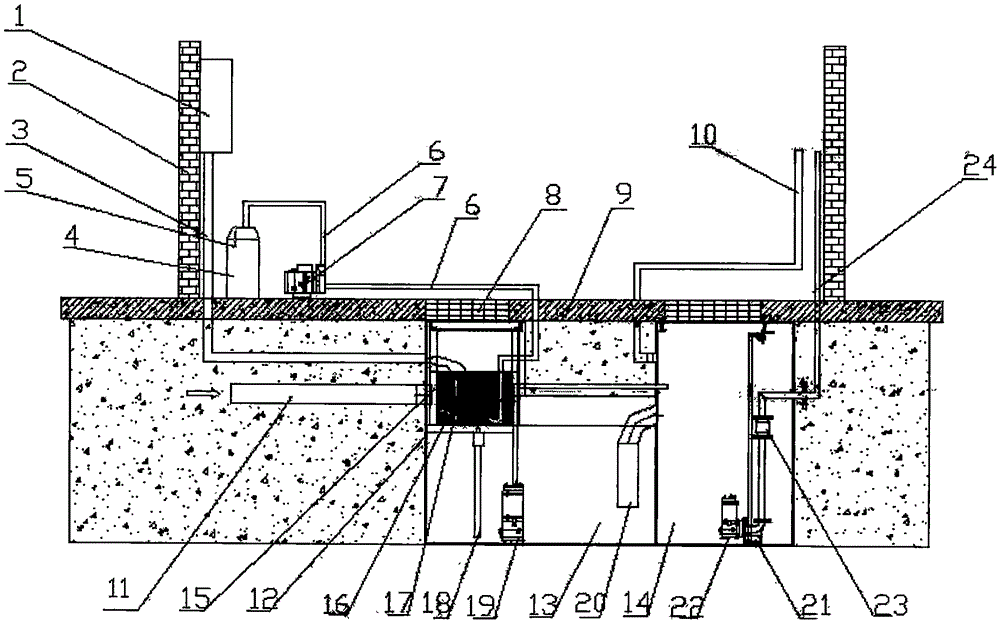

[0015] Embodiment 1, an underground oil-water separator, which is buried in a steel plate box (13) below the ground (9), and the steel plate box (12) is divided into an oil-water separation bin (13) and a sewage sedimentation bin (14) , the bottom of the oil-water separation bin (13) is connected with the sewage sedimentation bin (14) through the drain pipe (20), and the top ground of the oil-water separation bin (13) and the sewage sedimentation bin (14) is provided with an inspection port (8), and the inspection port (8 ) is provided with a cover plate to seal the steel plate box (12), oil and water enter the oil-water separation chamber (13) of the steel plate box (12), the filter blue (16) filters out the residue, and when the filter blue (16) is full of residue, pass through The inspection port (8) of the oil-water separation chamber (13) opens the cover plate, lifts the filter basket (16) and pours out the residue, then restricts the filter basket (16) to the filter baske...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com