A high-efficiency air cooling device

An air-cooling device and air-cooling technology, used in workpiece cooling devices, workpiece surface treatment equipment, metal rolling, etc., can solve the problem of uniformity of the upper surface of the wire, which needs to be improved, the lower surface cannot be uniformly sprayed and cooled, and the upper and lower surfaces of the wire. Uneven cooling and other problems, to facilitate later equipment maintenance, improve production flexibility, and improve the competitiveness of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

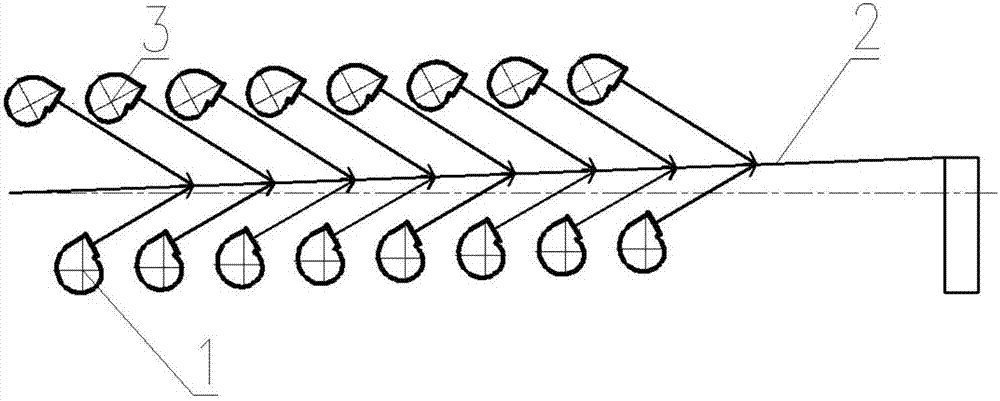

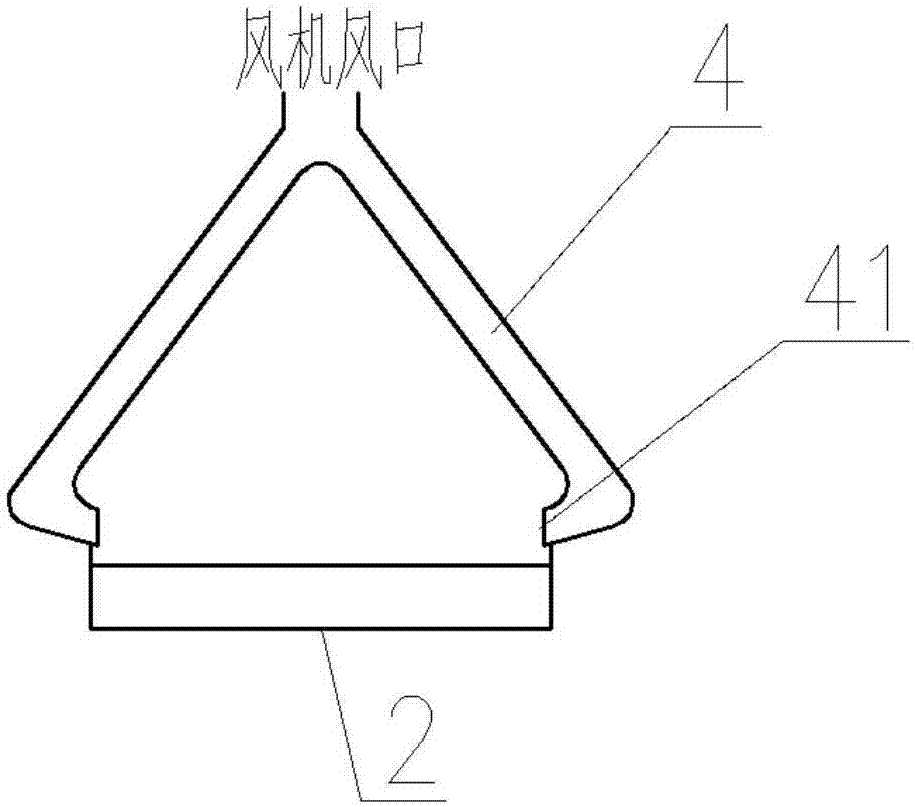

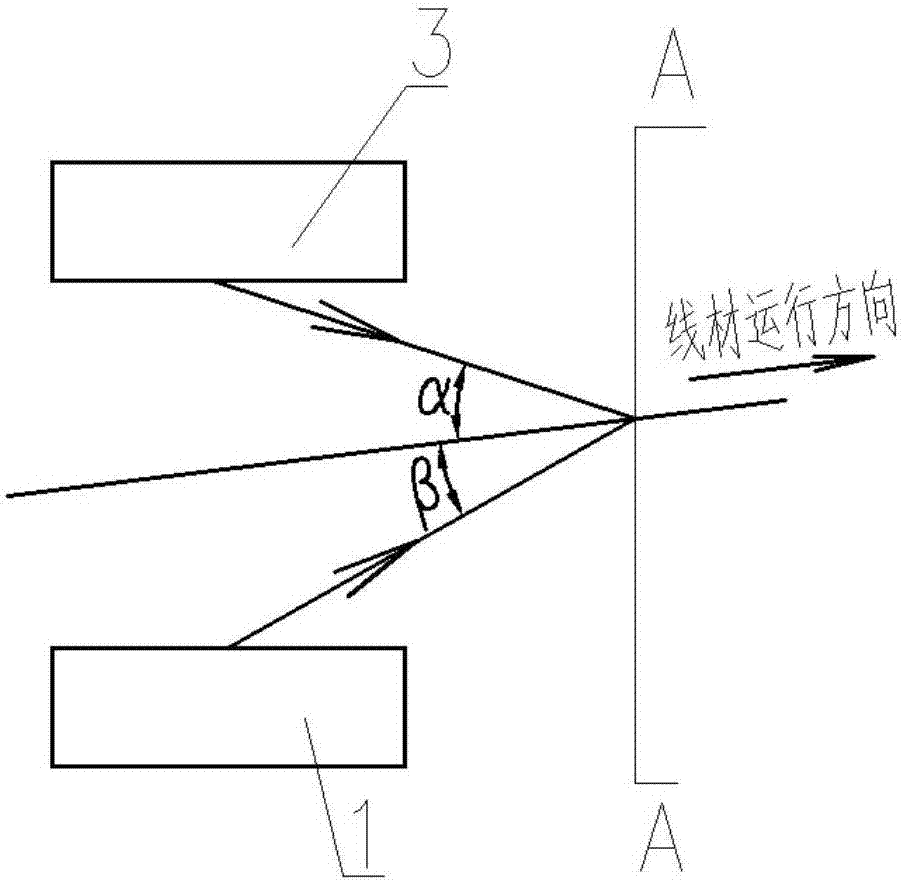

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, when the off-line fan 1 of the high-speed wire Stelmo air-cooled line is a 45° inclined fan, 6 to 16 sets of off-line fans 3 are arranged in sequence under the air-cooled roller table 2 of the Stelmo air-cooled line along the wire running direction At the same time, 6 to 16 fans 3 are correspondingly arranged on one side of the lower fan 1 or above the air-cooled roller table 2, and the fans 3 send air to the wire through the blowing duct 4 for cooling. The blowing pipe 4 has two air outlets 41 and the two air outlets are correspondingly located on both sides of the air-cooled roller table 2. The angle α between the blowing pipe 4 and the air-cooled roller table 2 in the wire running direction is 15° to 90°. The angle γ between the side blowing direction and the air-cooled roller table 2 is 0-90°. By controlling the layout position and air supply angle of the blowing duct 4, it ...

Embodiment 2

[0040] Such as Figure 7 , Figure 8 and Figure 4 As shown, when the off-line fan 1 of the high-speed wire rod Stelmore air-cooling line is a vertical fan, 8 to 12 down-fan fans are arranged in turn along the running direction of the wire rod under the air-cooling roller table of the Stelmore air-cooling line, and at the same time 8 to 12 fans 3 are correspondingly arranged on one side of the fan or above the air-cooled roller table 2, and the fans send air to the wire through the blowing duct for cooling. The blowing pipe has two air outlets and the two air outlets are located on both sides of the air-cooled roller table. The angle α between the blowing pipe and the air-cooled roller table in the direction of wire rod running is 15°-90°. The angle γ between the air-cooled roller tables is 0-90°. By controlling the layout position of the blowing duct and the air supply angle, it can ensure that the cooling air blown by the fan can completely cover the wire coil, which can ...

Embodiment 3

[0043] When the off-line fan of the high-speed wire rod Stelmore air-cooled line is a vertical fan, 10 to 14 down-fans are arranged in turn along the running direction of the wire below the air-cooled roller table of the Stelmo air-cooled line, and at the same time, on the side of the down-fan Or 10 to 14 fans are correspondingly arranged above the air-cooled roller table, and the fans send air to the wire through the blowing duct for cooling. The blowing duct has two air outlets and the two outlets are located on both sides of the air-cooled roller table. The angle α between the blowing pipe and the air-cooled roller table in the direction of wire rod running is 30°-60°. The angle γ between the air-cooled roller tables is 15-70°. By controlling the layout position of the blowing duct and the air supply angle, it can ensure that the cooling air blown by the fan can completely cover the wire coil, which can effectively improve the cooling strength of the air-cooled line and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com