Profile shaping method for machining cutter tooth main cutting edge according to cycloid bevel gear

A technology of main cutting edge, bevel gear, applied in the direction of gear tooth manufacturing tool, gear tooth manufacturing device, element with teeth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

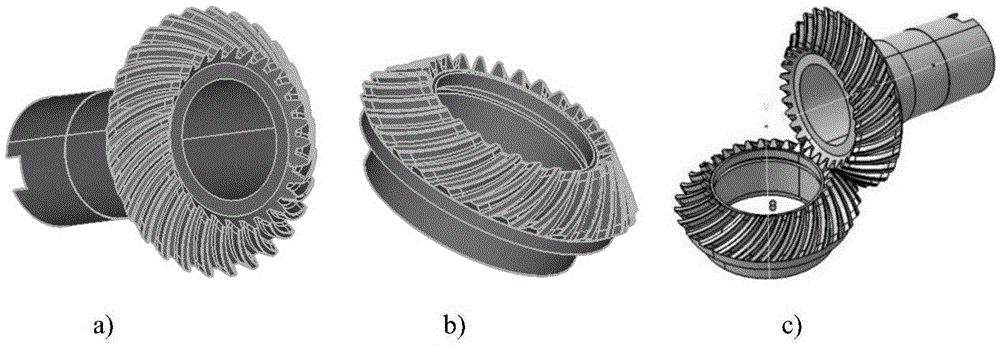

[0018] Through the following description in conjunction with the accompanying drawings, the present invention will be clearer, and the accompanying drawings are used to explain the methods and embodiments of the present invention.

[0019] The invention provides a contour modification method for the main cutting edge of a cutter tooth of a cycloid bevel gear. The specific implementation steps are as follows:

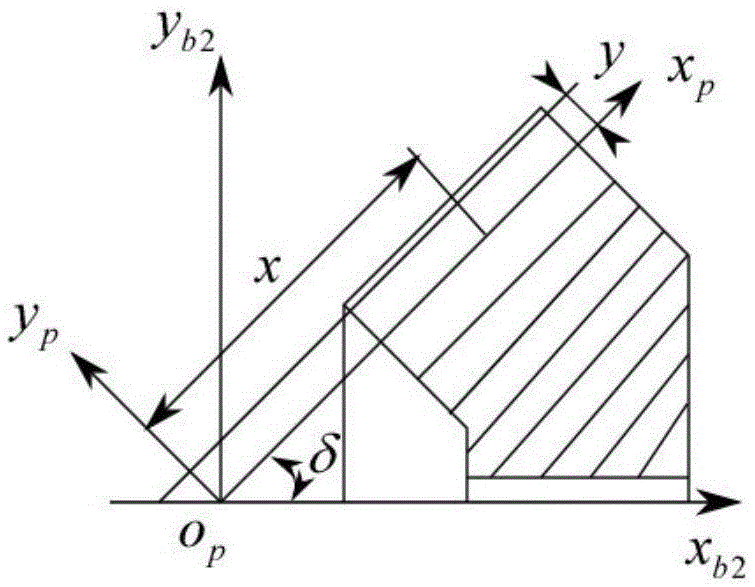

[0020] 1Traditional linear cutter tooth cutting edge model

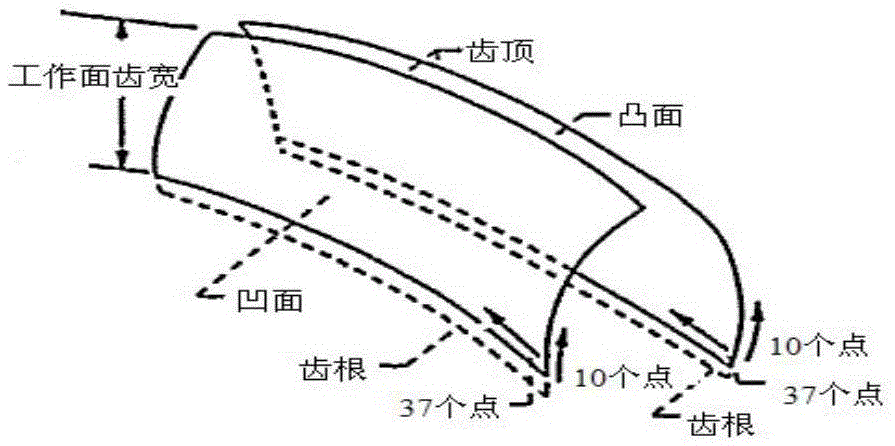

[0021] Traditional machining of cycloid bevel gears often uses linear cutting edges, and then modifies the gear teeth by adjusting the size parameters of the machine tool. This not only makes the machining parameters too complicated but also affects the tooth surface profile. The surface profile of the cutting edge of the linear cutter tooth, the convex and concave surfaces of the cutter tooth respectively cut the concave and convex surfaces of the gear, α g Tooth profile angle, arc radius ρ w The rounded corners of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com