Pressure maintaining apparatus, machine tool, and method of running pressure maintaining apparatus in machine tool

A technology of pressure maintaining device and hydraulic device, which is applied in the direction of fluid pressure actuating device, mechanical equipment, metal processing mechanical parts, etc., can solve the problems of power consumption reduction, oil leakage, etc., and achieve the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

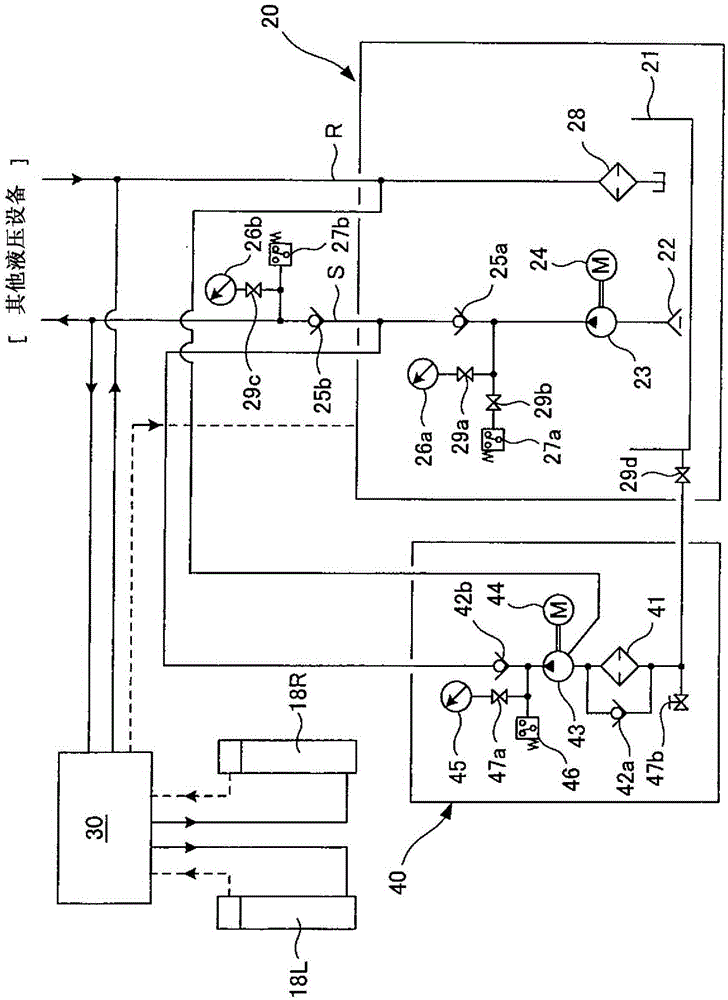

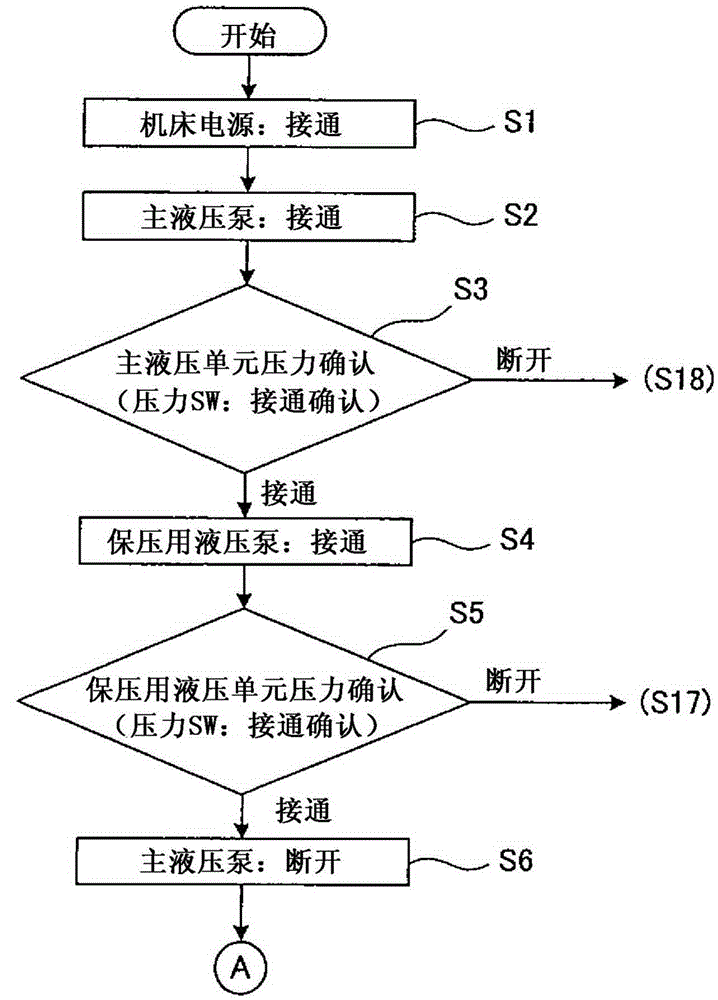

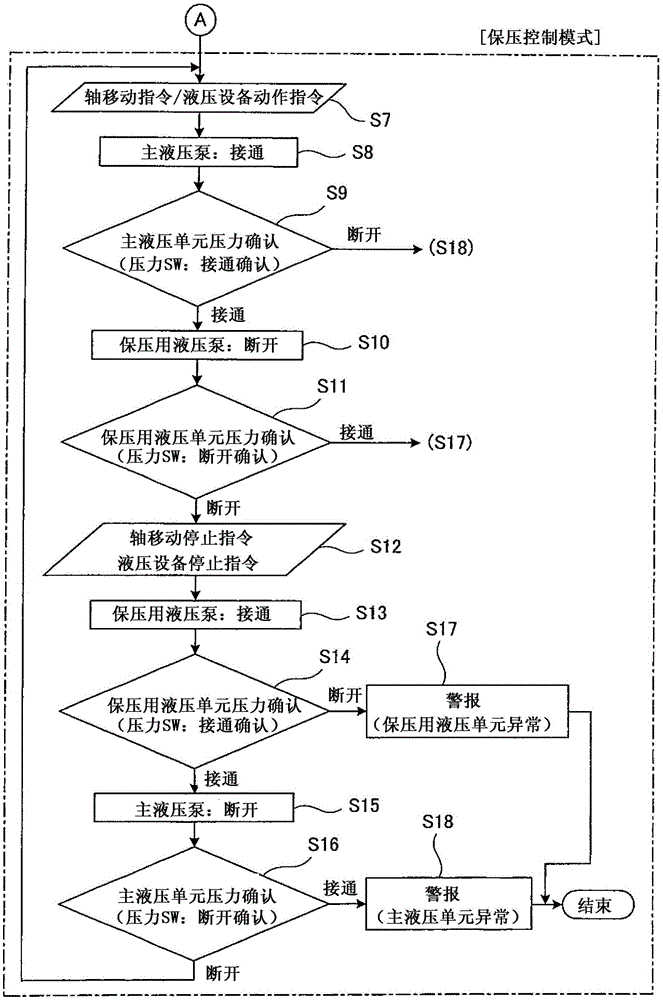

[0058] figure 1 It is a hydraulic system diagram showing the pressure maintaining device of this embodiment. in addition, Figure 2 ~ Figure 3 is true figure 1 The flow chart illustrating the operation of the pressure holding device shown in Figure 4 is true figure 1 A time chart illustrating the operation of the pressure holding device is shown.

[0059] The pressure maintaining hydraulic unit 40 (pressure maintaining device) of this embodiment is a structure that can be added to the existing main hydraulic unit 20 (main hydraulic device). Like the prior art, it can be adjusted through a pressure adjustment unit that balances the pressure. 30. Supply pressure oil to the hydraulic balance cylinders 18L, 18R of the machine tool 10.

[0060] refer to figure 1 The configuration of the main hydraulic unit 20 will be described. The main hydraulic unit 20 has: an oil tank 21 for storing oil; a filter 22 for removing solid content from the oil tank 21 to suck the oil; and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com