Support structure part and spring leg bushing for connecting spring leg to vehicle body

A supporting structure and spring leg technology, which is applied to vehicle parts, superstructures, superstructure sub-assemblies, etc., can solve the problems of limited design space, automobile production progress, manufacturing cost and repair friendliness, and achieve durable and firm fixation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

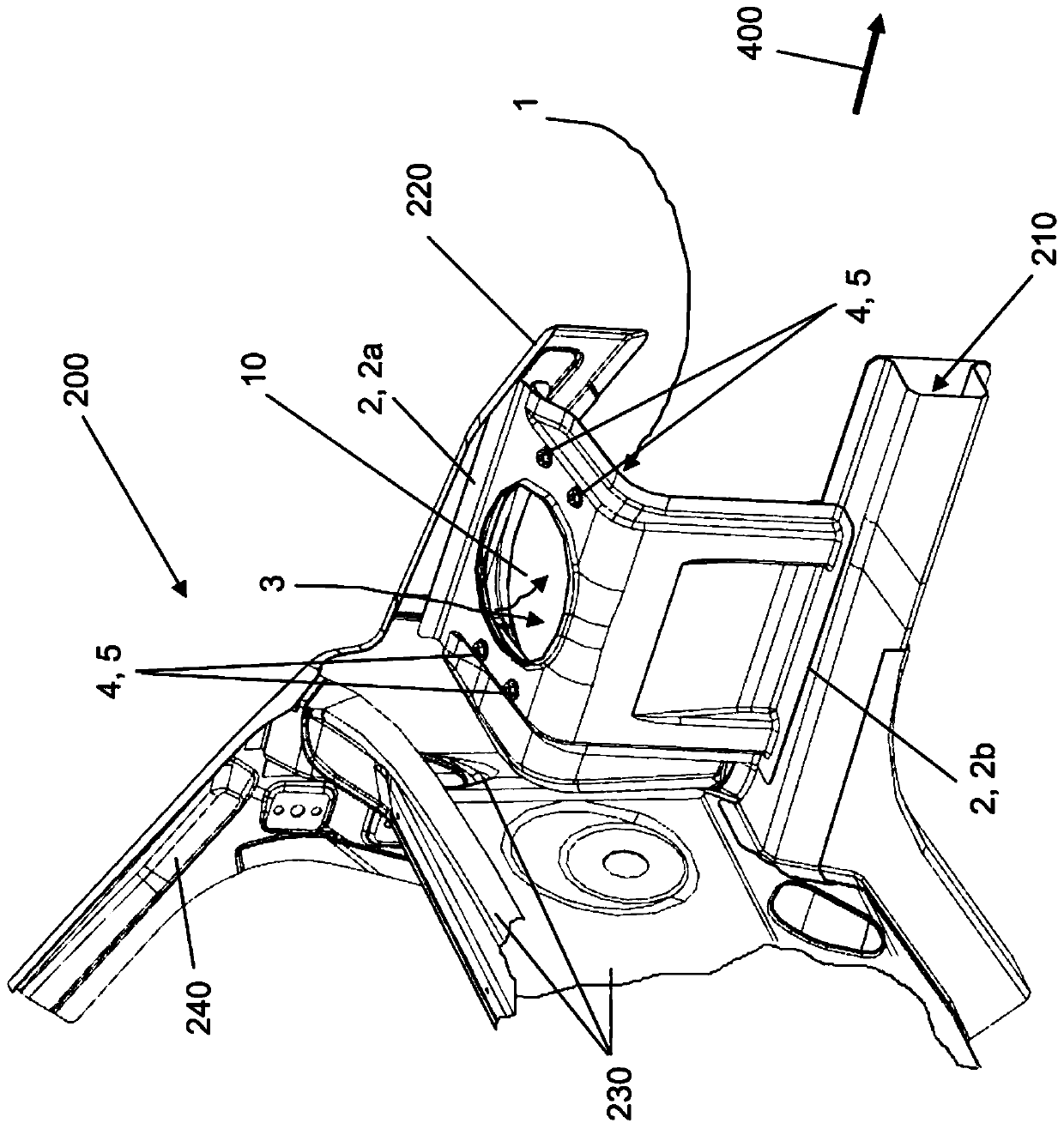

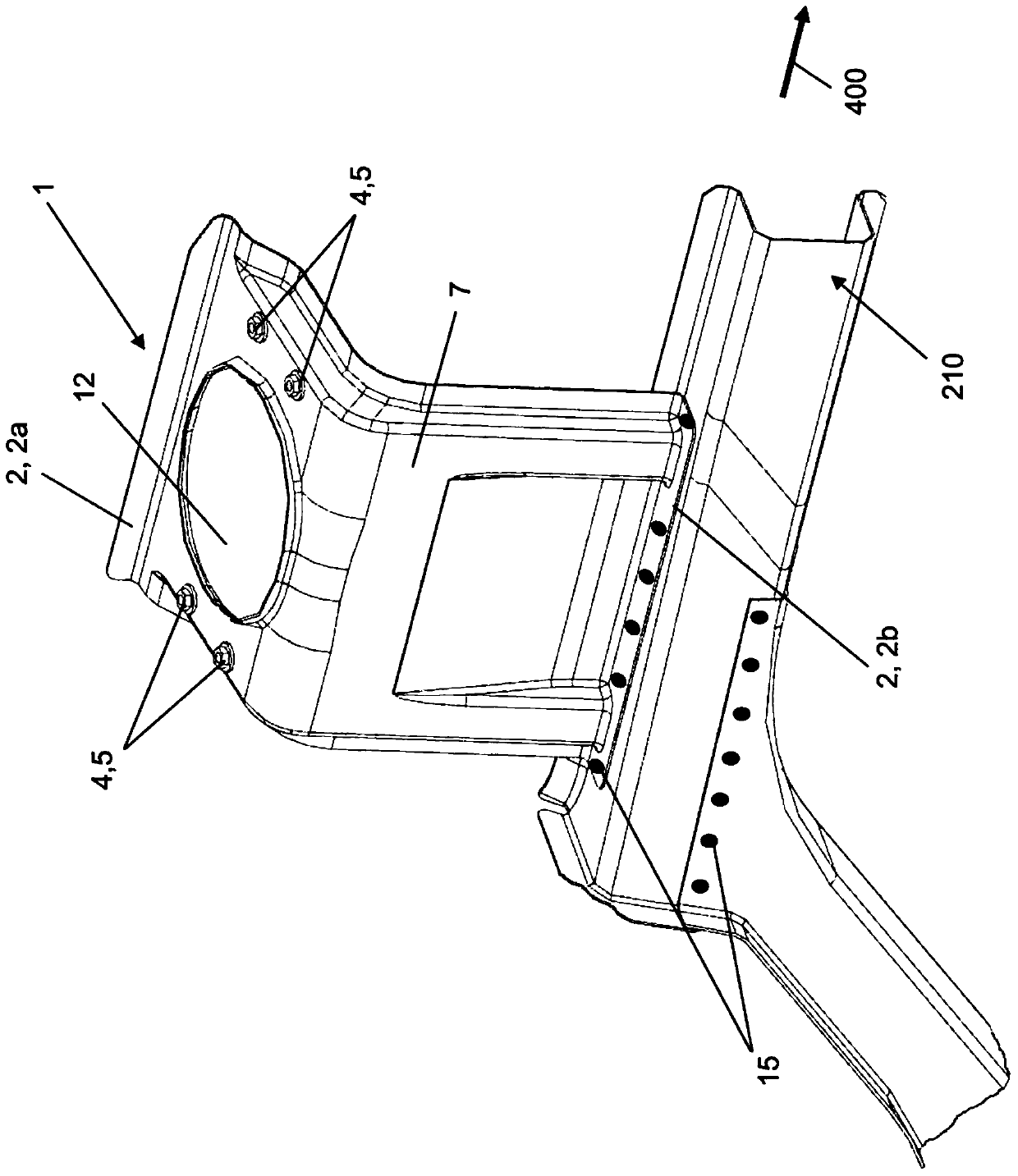

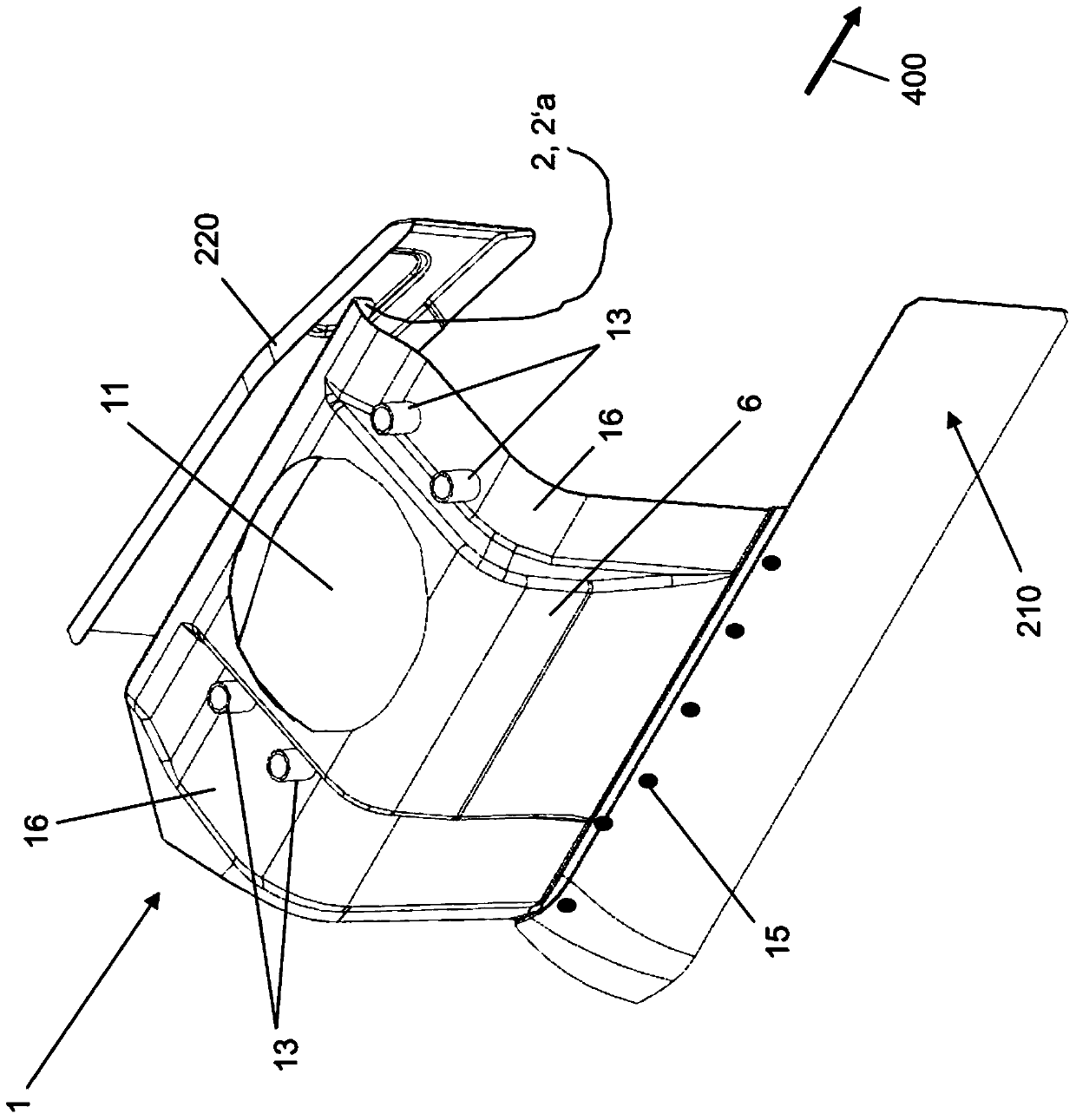

[0039] figure 1 A possible embodiment of a vehicle body 200 is shown schematically, for example showing the left-hand region of its front. Depend on figure 1 A side member 210 of the vehicle body 200 and a longitudinal structure 220 extending at a distance from the side member are shown. The longitudinal structure 220 may be a wheel mounting support. In addition, by figure 1 A dash panel 230 is also shown at least partially, which extends perpendicularly to the side members 210 and the longitudinal structure 220 and which can transition on the outside into a side dash panel 240 .

[0040] Viewed in forward direction of travel 400 , side member 210 and longitudinal structure 220 form a receiving space for vehicle wheels in a region in front of bulkhead 230 . In order to be able to place ( figure 1 The spring legs (not shown) are mounted on the vehicle body 200 and a supporting structural part 1 is provided which is connected to the vehicle body 200 by means of at least one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com