Treatment method of H acid production wastewater and equipment for implementing the method

A technology for the production of wastewater and treatment methods, which is applied in water/sewage treatment equipment, textile industry wastewater treatment, multi-stage water treatment, etc., can solve the problems of high cost of membrane separation technology and insufficient wastewater treatment, and achieve the goal of reducing COD value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

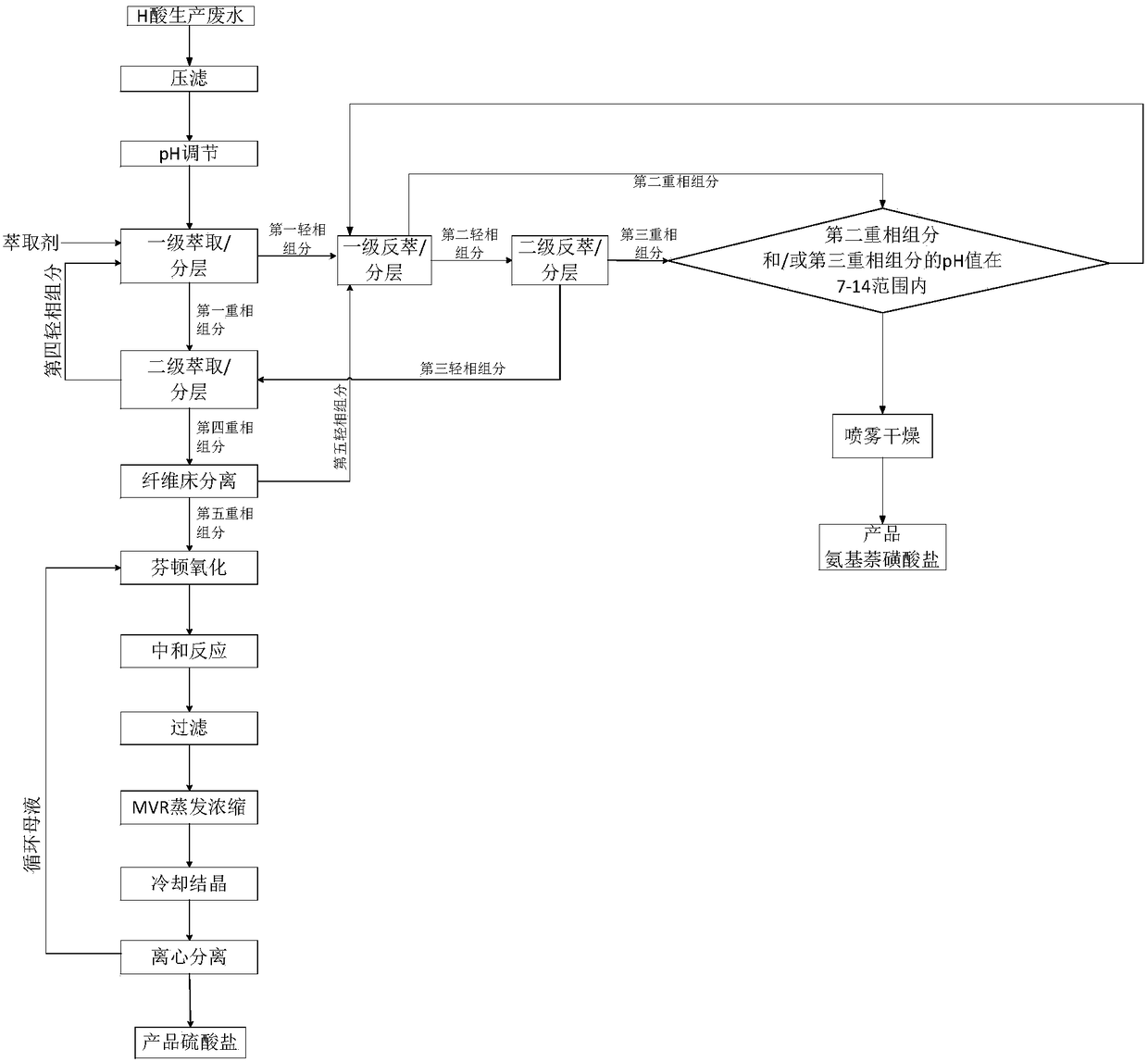

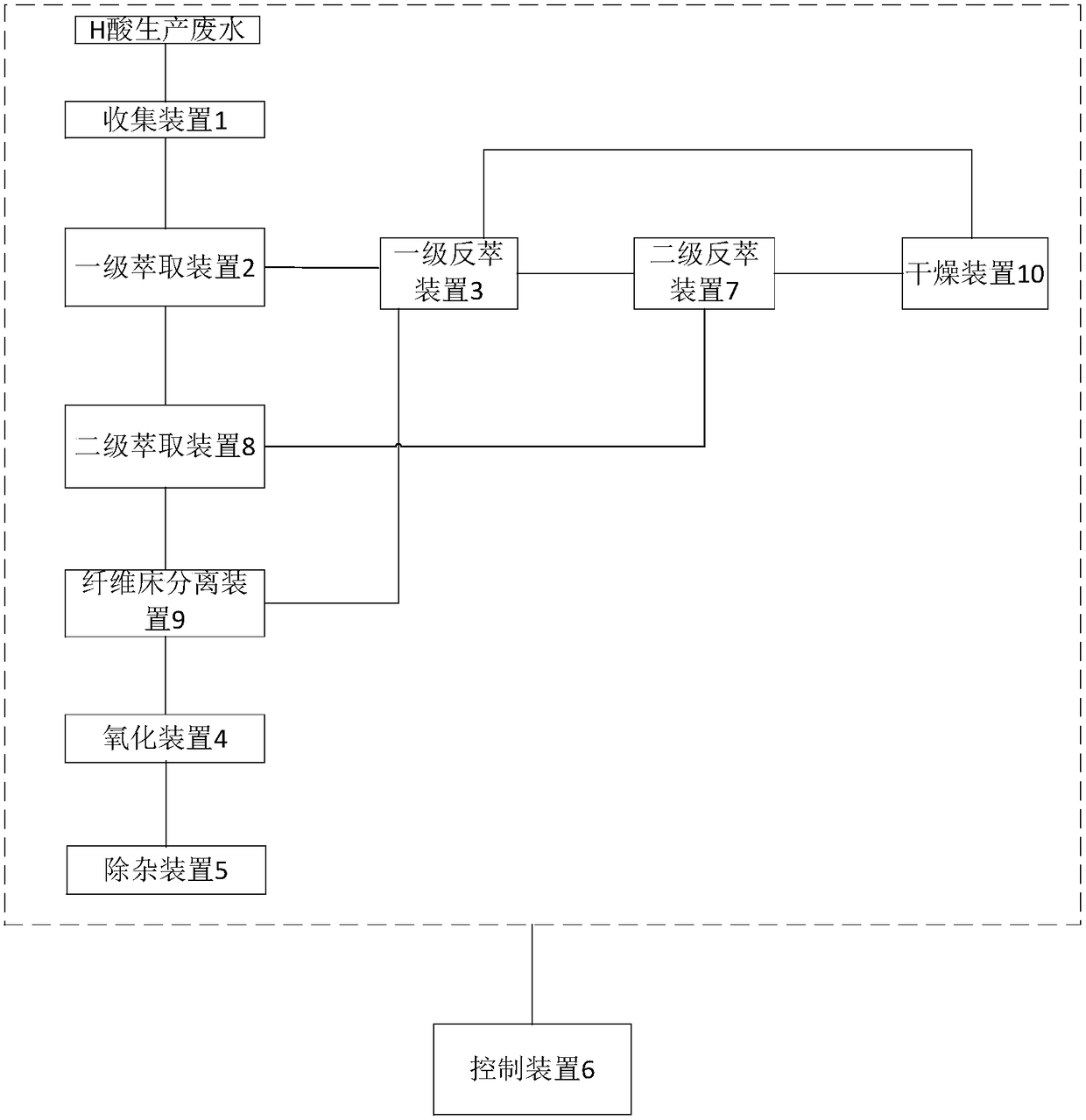

[0086] figure 1 A process flow diagram of a treatment method for H acid production wastewater according to an embodiment of the present invention is shown. Such as figure 1 As shown, collect 500mL of H-acid production wastewater (the H-acid production wastewater adopted in this embodiment is the T-acid wastewater in the production process), and after removing the insoluble matter in the T-acid wastewater, adjust the temperature to 60°C. The pH value was adjusted to 1.5 to obtain the first mixed solution. The first mixed solution is mixed with 1000mL of extractant, wherein, in the extractant, trioctylamine:n-octanol:sulfonated kerosene is 18.2:9.1:72.7; at a temperature of 60°C, extraction and separation are carried out to obtain A first light phase component and a first heavy phase component.

[0087] The first light phase component is mixed with 1500mL of 30% NaOH solution by mass percentage, and back-extracted and separated at a temperature of 60° C. to obtain the secon...

Embodiment 2

[0092] Collect 500mL of H-acid production wastewater (the H-acid production wastewater used in this embodiment is the H-acid wastewater in the production process), remove the insoluble matter in the H-acid wastewater, adjust the temperature to 60°C, and adjust the pH to 1.5 to obtain the first mixed solution. The first mixed solution is mixed with the extractant of 1000mL, wherein the extractant includes: complexing agent, cosolvent and diluent, wherein, the trioctylamine: n-octanol: sulfonated kerosene is 18.2:9.1: 72.7; at a temperature of 60° C., extract and separate to obtain the first light phase component and the first heavy phase component.

[0093] Mix the first light phase component with 30% 1500mL NaOH solution, and carry out back extraction and separation at a temperature of 60° C. to obtain the second light phase component and the second heavy phase component; The second light phase component was mixed with 150 mL of 30% NaOH solution by mass percentage, and back-...

Embodiment 3

[0098] Collect 500mL of H-acid production wastewater (the H-acid production wastewater used in this example is the T-acid wastewater in the production process), remove the insoluble matter in the T-acid wastewater, adjust the temperature to 60°C, and adjust the pH to 1.5 to obtain the first mixed solution. The first mixed solution is mixed with the extractant of 500mL, wherein, the extractant includes: complexing agent, cosolvent and diluent, wherein, the trioctylamine: n-octanol: sulfonated kerosene is 18.2:9.1: 72.7; at a temperature of 60° C., extract and separate to obtain the first light phase component and the first heavy phase component.

[0099] The first light phase component is mixed with 1000mL of 30% NaOH solution by mass percentage, and stripped and separated at a temperature of 60° C. to obtain the second light phase component and the second heavy phase component; The second light phase component was mixed with 100 mL of 30% by mass NaOH solution, and stripped a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com