Carbon nanostructured composite polyurethane foam and its preparation method and use

A technology of carbon nanostructure and composite polyurethane, which is applied in the field of carbon nanostructure composite polyurethane foam, preparation and application, and can solve problems such as harsh process conditions, complicated pretreatment, and materials without far-infrared functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Embodiment 1 provides a kind of preparation method of composite polyurethane foam, and specific condition is:

[0083] In step (2), the second catalyst is ferrous chloride; the mixing mass ratio of porous cellulose and the second catalyst is 1:0.1; the catalytic treatment temperature is 150°C, and the time is 4h; the moisture content in the precursor is 10wt %;

[0084] The process of obtaining the crude product is as follows: heat up to 280°C at a rate of 3°C / min, hold for 2 hours, then heat up to 950°C at a rate of 15°C / min, and hold for 3 hours;

[0085] The pickling temperature is 55°C, and the concentration of hydrochloric acid used in pickling is 4wt%;

[0086] The carbon nanostructure compound obtained in step (2) mainly contains P, Si, Ca, Al, Na, Fe, Mg elements; and the Raman spectrum shows that the peak height ratio of G peak and D peak is 7; there is 2D peak;

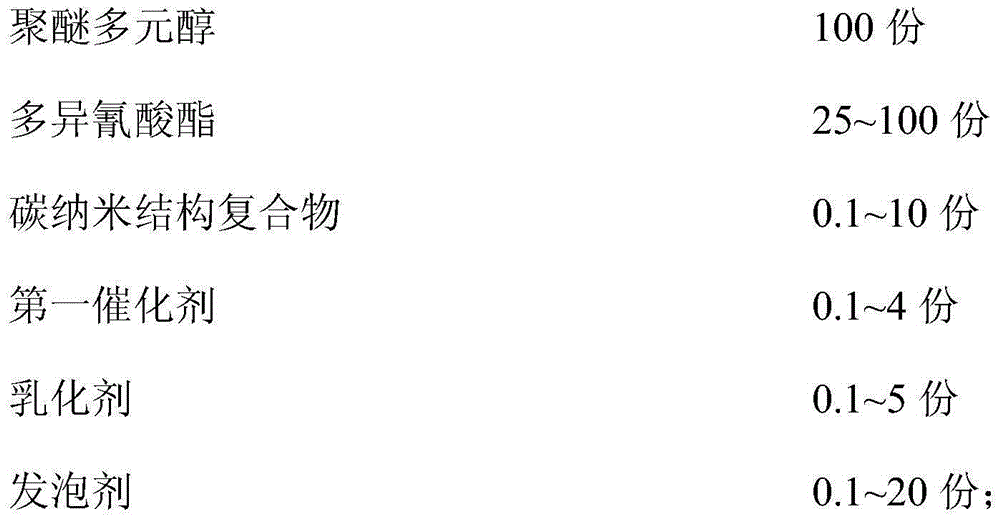

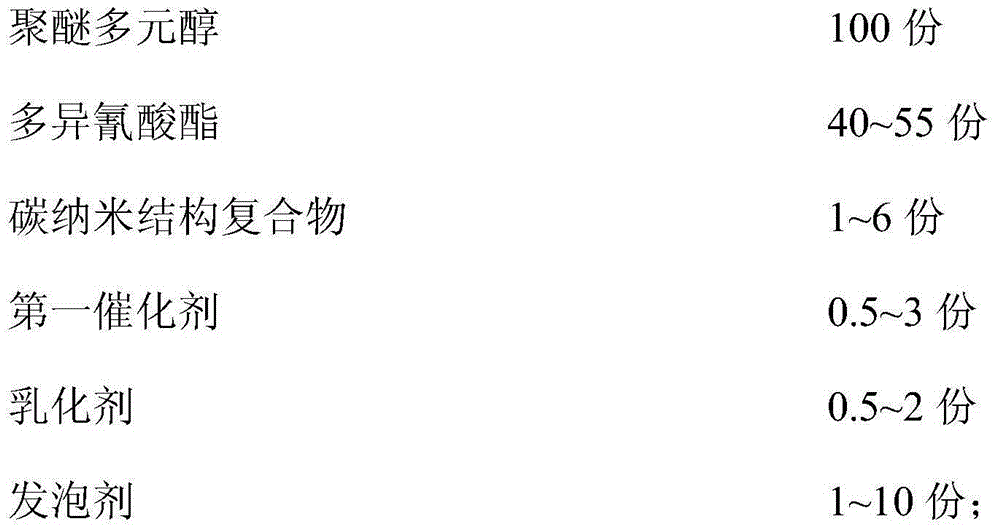

[0087] In the step (3), the raw material composition used comprises the following components in...

Embodiment 2

[0090] Embodiment 2 provides a kind of preparation method of complex polyurethane foam, and specific conditions are compared with embodiment 1, and difference only is that in step (3), the addition amount of the carbon nanostructure composite of raw material composition used is 0.1 weight part.

Embodiment 3

[0091] Embodiment 3 provides a kind of preparation method of composite polyurethane foam, and specific conditions are compared with embodiment 1, and difference is only in step (3), the addition amount of the carbon nanostructure composite of raw material composition used is 10 parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com