A composite polyurethane foam containing graphene, its preparation method and use

A technology of polyurethane foam and graphene, applied in the direction of graphene, nano-carbon, etc., can solve the problems of complex pretreatment, harsh process conditions, and materials without far-infrared function, and achieve simple process, obvious antibacterial performance, and obvious far-infrared function performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

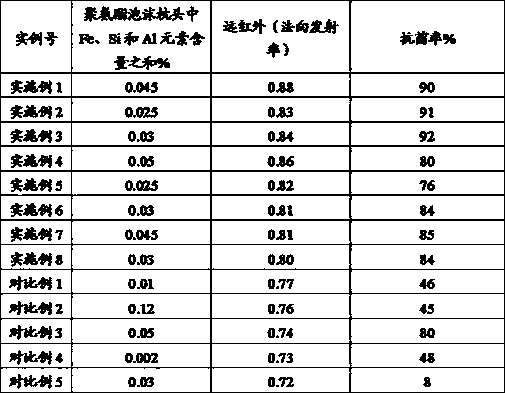

Examples

preparation example Construction

[0104] The invention provides the preparation method of the polyurethane foam containing graphene structure, comprises the steps:

[0105] A substance containing a graphene structure and non-carbon, non-oxygen, and non-hydrogen elements is introduced into the polyether polyol to prepare a polyurethane foam containing a carbon nanostructure.

[0106] The graphene structure of the present invention is preferably introduced in the form of a mixture, which preferably includes non-graphene structure components, such as amorphous carbon components.

[0107] The present invention provides a product, containing the polyurethane foam described in any one of the above technical solutions, or the polyurethane foam prepared by the preparation method described in any one of the above technical solutions; the product preferably includes pillows, mattresses, cushions, Cushions, sofas, waist supports, insoles, bras, car seats, toilet seats or hand warmers.

[0108] The polyurethane foam prov...

Embodiment 1

[0115] A compound containing carbon nanostructure obtained by the following method:

[0116] (1) Mix corn cob cellulose and ferrous chloride at a mass ratio of 1:1, stir at 150°C for 4 hours, and dry until the moisture content of the precursor is 10wt%, to obtain the precursor;

[0117] (2) In a protective atmosphere, raise the temperature of the precursor to 170°C at a rate of 3°C / min, hold for 2 hours, then program the temperature to 400°C, hold for 3 hours, then raise the temperature to 1200°C, hold for 3 hours to obtain the crude product; the procedure The heating rate is 15°C / min;

[0118](3) At 55-65°C, the crude product was pickled with 10% sodium hydroxide solution and 4wt% hydrochloric acid, and then washed with water to obtain a composite containing carbon nanostructures.

[0119] The composite of the carbon nanostructure prepared in Example 1 was subjected to Raman spectrum detection, and the results showed that the peak height ratio of the G peak and the D peak wa...

Embodiment 2

[0122] The corn cob cellulose in Example 1 is replaced by reed cellulose.

[0123] The composite of carbon nanostructures prepared in Example 2 was detected by Raman spectroscopy, and the results showed that the G peak and D peak height ratios were 4.8;

[0124] The first non-carbon, non-oxygen, and non-hydrogen element content determination method is used to detect that the composite containing carbon nanostructures mainly contains Si, Ca, Al, Fe, Mg, and S elements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com