External wall insulation sandwiched casing mold fireproof wallboard for building wall

A technology for thermal insulation of external walls and building walls, which is applied in the field of thermal insulation materials for external walls of buildings. It can solve the problems that thermal insulation materials for external walls of walls cannot play a role in fire prevention, poor fixing strength of thermal insulation materials, and short service life. It achieves the effects of good flame-proof and fire-proof effect, guaranteed strength and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

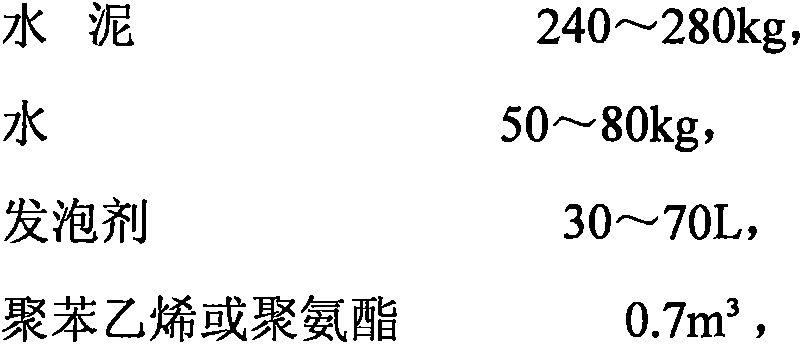

Embodiment 1

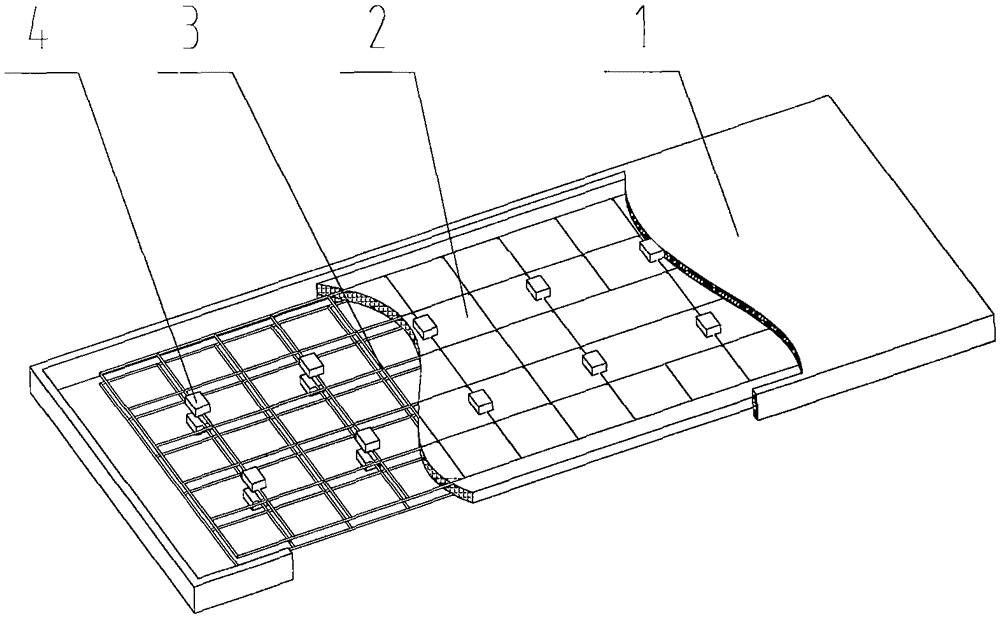

[0023] The reinforced steel mesh 3 is rectangular, and a rectangular middle insulation core 2 is arranged between the two layers of reinforced steel mesh 3, and a connecting steel wire is set through the middle insulation core 2 between the two layers of reinforced steel mesh 3 to make the two layers of reinforced steel mesh 3 and the middle insulation core 2 is connected as a whole plate-shaped inner skeleton, and at least four pairs of fixed support frames 4 are arranged symmetrically above and below the two-layer reinforced steel mesh 3;

[0024] The plate-shaped inner skeleton provided with the fixed support frame 4 is put into the middle part of the mold box with a cuboid cavity as a whole, and the upper plane of the fixed support frame 4 above the two-layer reinforced steel mesh 3 is closely attached to the inner upper surface of the mold box, and the two sides The lower plane of the fixed support frame 4 below the layer of reinforced steel mesh 3 is closely attached to t...

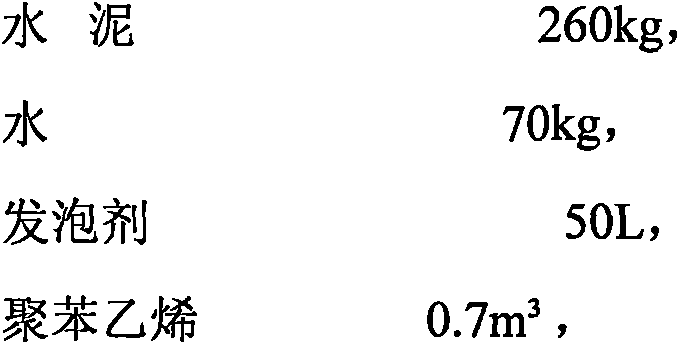

Embodiment 2

[0034] The reinforced steel mesh 3 is rectangular, and a rectangular middle insulation core 2 is arranged between the two layers of reinforced steel mesh 3, and a connecting steel wire is set through the middle insulation core 2 between the two layers of reinforced steel mesh 3 to make the two layers of reinforced steel mesh 3 and the middle insulation core 2 is connected as a whole plate-shaped inner skeleton, and at least four pairs of fixed support frames 4 are arranged symmetrically above and below the two-layer reinforced steel mesh 3;

[0035] The plate-shaped inner skeleton provided with the fixed support frame 4 is put into the middle part of the mold box with a cuboid cavity as a whole, and the upper plane of the fixed support frame 4 above the two-layer reinforced steel mesh 3 is closely attached to the inner upper surface of the mold box, and the two sides The lower plane of the fixed support frame 4 below the layer of reinforced steel mesh 3 is closely attached to t...

Embodiment 3

[0045] The reinforced steel mesh 3 is rectangular, and a rectangular middle insulation core 2 is arranged between the two layers of reinforced steel mesh 3, and a connecting steel wire is set through the middle insulation core 2 between the two layers of reinforced steel mesh 3 to make the two layers of reinforced steel mesh 3 and the middle insulation core 2 is connected as a whole plate-shaped inner skeleton, and at least four pairs of fixed support frames 4 are arranged symmetrically above and below the two-layer reinforced steel mesh 3;

[0046] The plate-shaped inner skeleton provided with the fixed support frame 4 is put into the middle part of the mold box with a cuboid cavity as a whole, and the upper plane of the fixed support frame 4 above the two-layer reinforced steel mesh 3 is closely attached to the inner upper surface of the mold box, and the two sides The lower plane of the fixed support frame 4 below the layer of reinforced steel mesh 3 is closely attached to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com