Crankshaft starter generator

A technology for starters and generators, which is applied in the directions of engine components, engine starting, machine/engine, etc., and can solve problems such as obstacles to starting operations and complicated starter crown gears.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

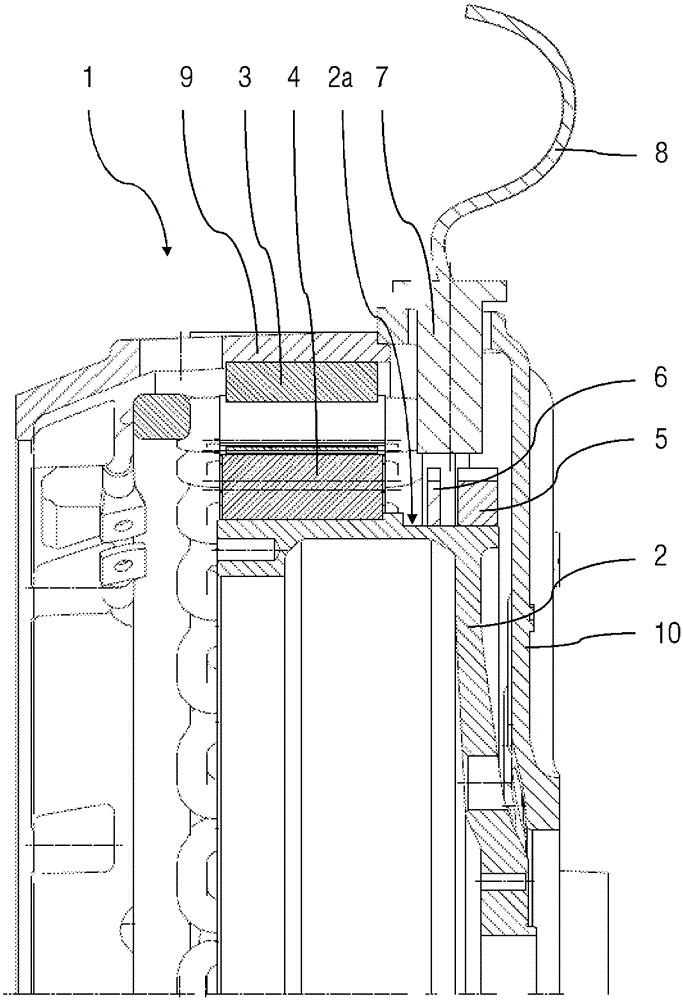

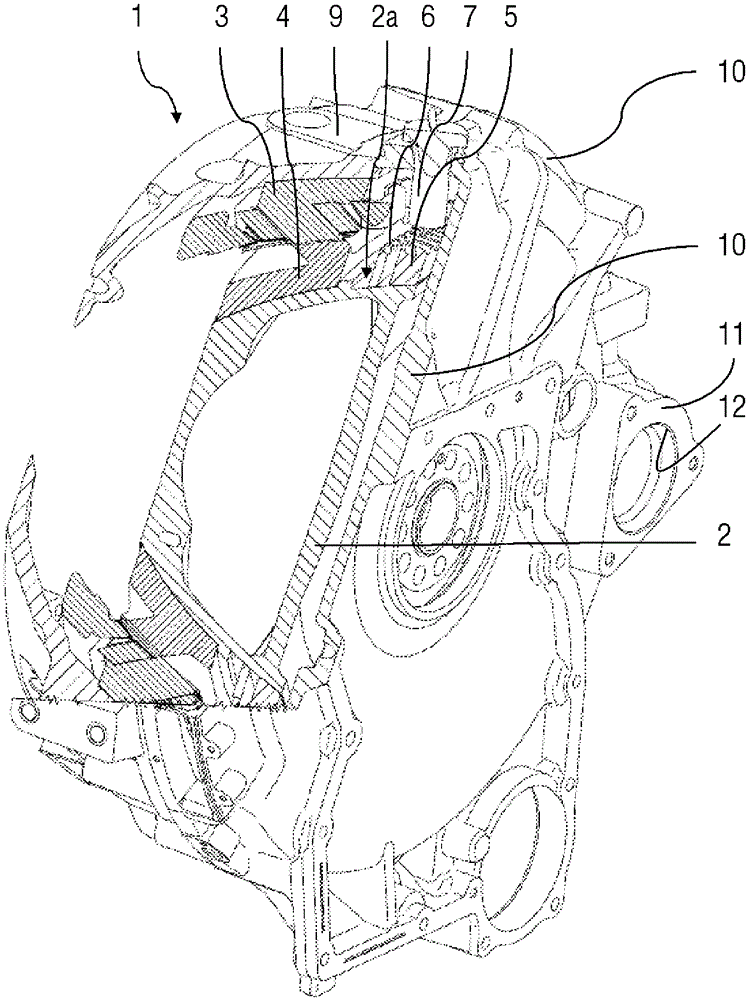

[0018] figure 1 A cross-sectional view of the upper half of a crank starter generator according to one embodiment of the invention is shown. A crank starter generator 1 is positioned between a gearbox and an internal combustion engine (not shown here) in the drive train of a motor vehicle. The crank starter generator includes a CSG housing 9 which may have a splittable configuration. The stator 3 is fixed on the inner periphery of the CSG case 9 . The stator is formed of magnetic steel plates and windings of the stator, the magnetic steel plates are joined to each other and welded to each other, and the windings of the stator are housed inside. Furthermore, the crank starter generator 1 includes a rotor 4 which is fixedly arranged on the cylindrical peripheral surface 2 a of the rotor bracket 2 to rotate therewith. The rotor carrier is part of flywheel 2. A cylindrical peripheral surface 2 a extending in the axial direction is integrally formed on the outer peripheral regi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com