High pressure injected air oxidation heat effect detecting and tracking experimental device and method

A detection tracking and experimental device technology, applied in measurement devices, material inspection products, instruments, etc., can solve problems such as low degree of automation, inability to reflect changes in thermal effects, and inability to realize research on thermal effects of crude oil oxidation, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

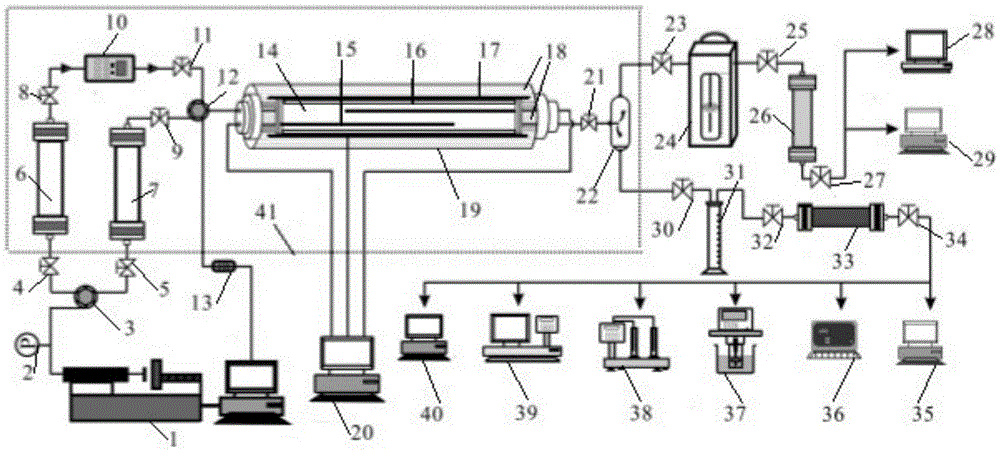

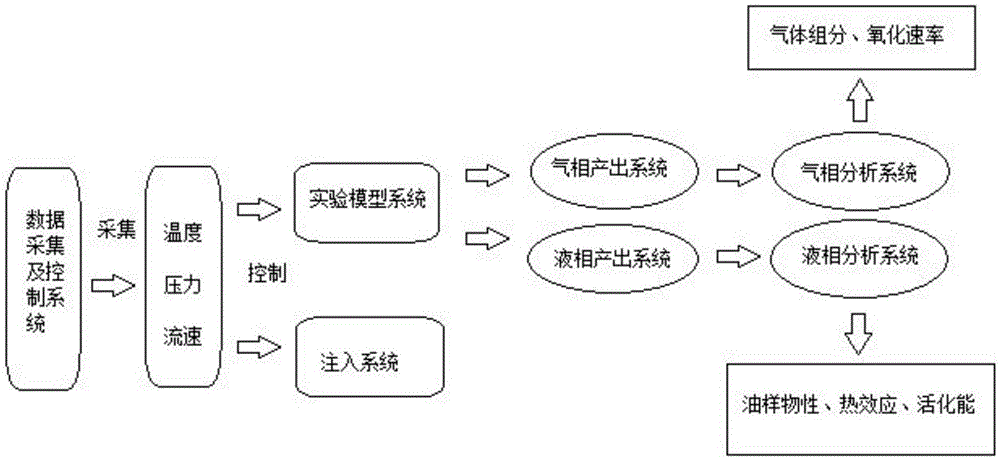

Method used

Image

Examples

Embodiment 1

[0045] A specific example 1 is given below to describe the experimental process of this experimental method.

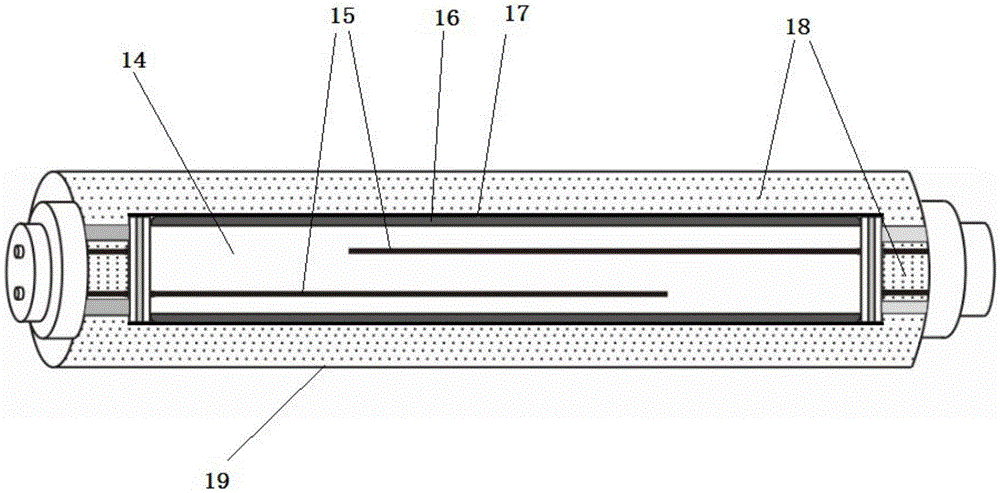

[0046] In this example, the constant temperature reaction mode is used to study the thermal effect of oxidation of crude oil and high-pressure air in the model system. Adjust the temperature of the heating belt 16 in the constant temperature oven 41 and the thermal effect tracker 19 to the experimental temperature of 120°C, keep the temperature for more than 2 hours, and start the sample injection process after the detection record of the temperature detection and control device 20 shows that the temperature is stable.

[0047] Fully heat the gas sample cylinder 6 and oil sample cylinder 7 in the oven at 120°C; when injecting samples, first open the six-way valve 1 3, valve 5 5, valve 9 9 and six-way valve 2 12, and control the pump 1 row Empty the air in the oil sample cylinder 7, and then set the multi-function control pump 1 to pump 50 mL of high-temperature oil sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com