Method for detecting whether wafer position inclines during baking process

A wafer tilting technology, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, electrical components, etc. To solve problems such as the normal use of the station, achieve the effects of high accuracy, convenient detection, and small temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

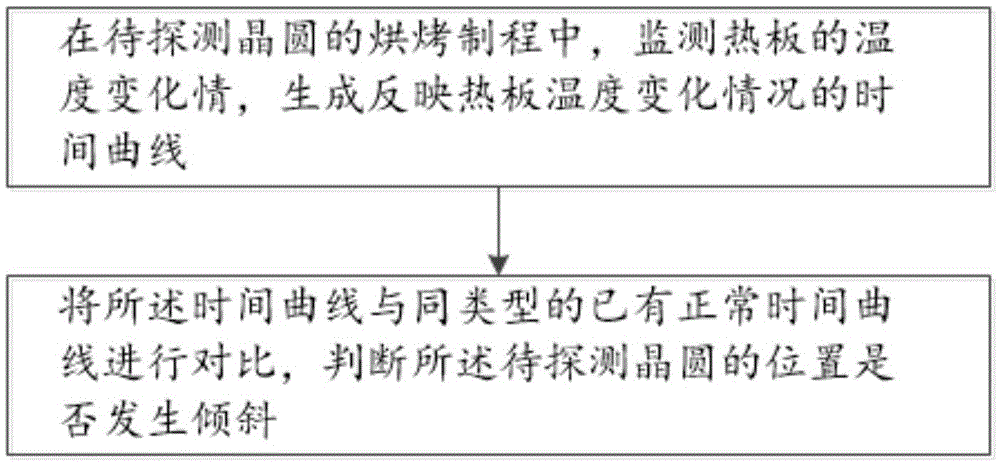

[0027] like figure 1 As shown, a method for detecting whether the wafer position is tilted in the baking process includes the following steps:

[0028] Step 1, during the baking process of the wafer to be detected, monitor the temperature change of the hot plate, and generate a time curve reflecting the temperature change of the hot plate;

[0029] Step 2, comparing the time curve with the existing normal time curve of the same type to determine whether the position of the wafer to be detected is tilted.

[0030] The existing normal time curve is statistically fitted from the time curves generated by a plurality of wafers of the same specification with the same specification as the wafer to be detected, and the bak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com