A horizontal fully automatic equal-diameter angular extrusion experimental device

A technology of equal angular extrusion and experimental equipment, which is applied in the direction of applying stable tension/pressure to test the strength of materials, which can solve the problems of difficult demoulding of samples, inconvenient experimental research, unfavorable experimental results, etc., to avoid temperature The effect of falling too fast, loading the sample quickly and conveniently, and reducing the technical level requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

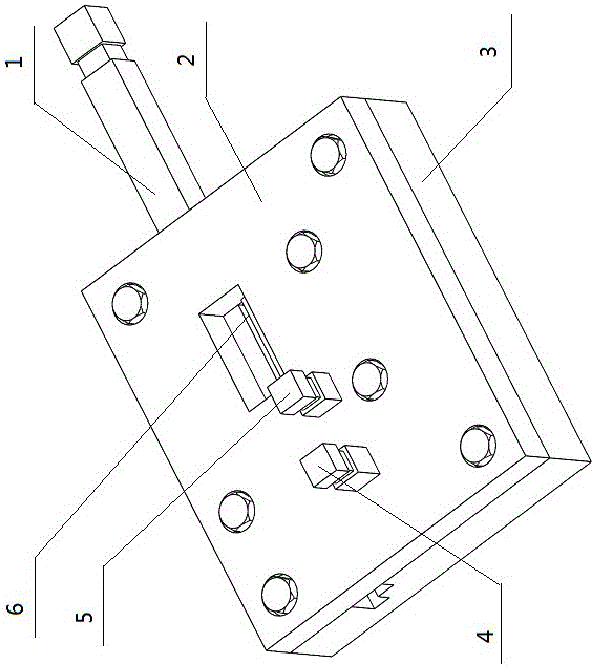

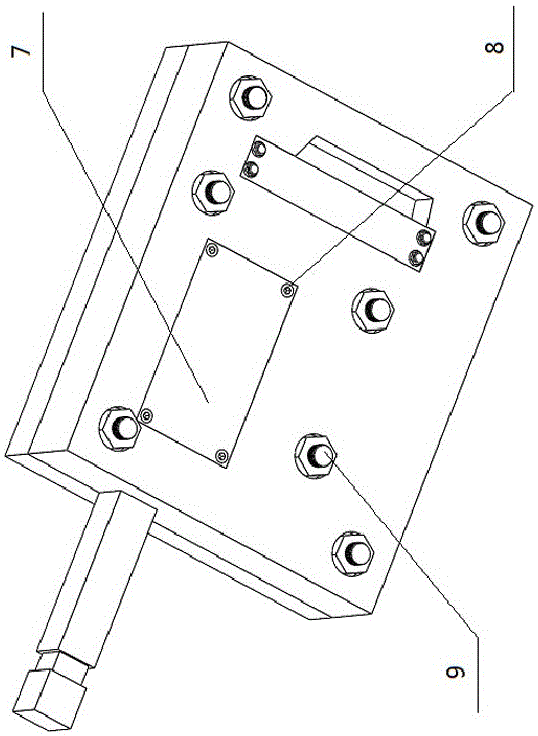

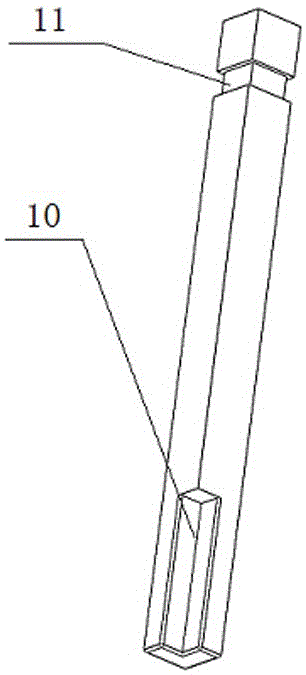

[0045] A horizontal full-automatic equal-diameter angular extrusion test device, including a push rod 1, an upper die 2, a lower die 3, a separation device 4, a pushing device 5, a filling device 6, a rear cover 7, and a rear cover lower die connecting bolt 8 , Connection bolts and nuts for upper and lower molds 9, sample chamber 10, connection groove a11, sample placement port 12, separation rod port 13, ejection rod port 14, upper film sink hole 15, through hole a16, ejection push block Boss 17, separation push block groove 18, spring hole a19, rear cover threaded hole 20, shaft groove 21, lower film sink hole 22, stud hole 23, equal-diameter angle channel 24, pushing out push block groove 25, loading support Groove 26, filling slider groove 27, extrusion channel 28, loading support 29, loading connecting rod 30, loading spring 31, loading slider 32, loading surface 33, rotating shaft 34, connecting rod shaft a35, slope 36, spring hole b37, connecting rod shaft b38, upper se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com