Composite heat storage body

A regenerative body and composite technology, which is applied in the direction of gas fuel burners, lighting and heating equipment, combustion methods, etc., can solve the problems of increased operating costs, high prices, and high cost of regenerative bodies, so as to improve heating uniformity , Increase heat content, shorten heat storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The compound heat accumulator of the present invention will be further described in detail through specific examples below.

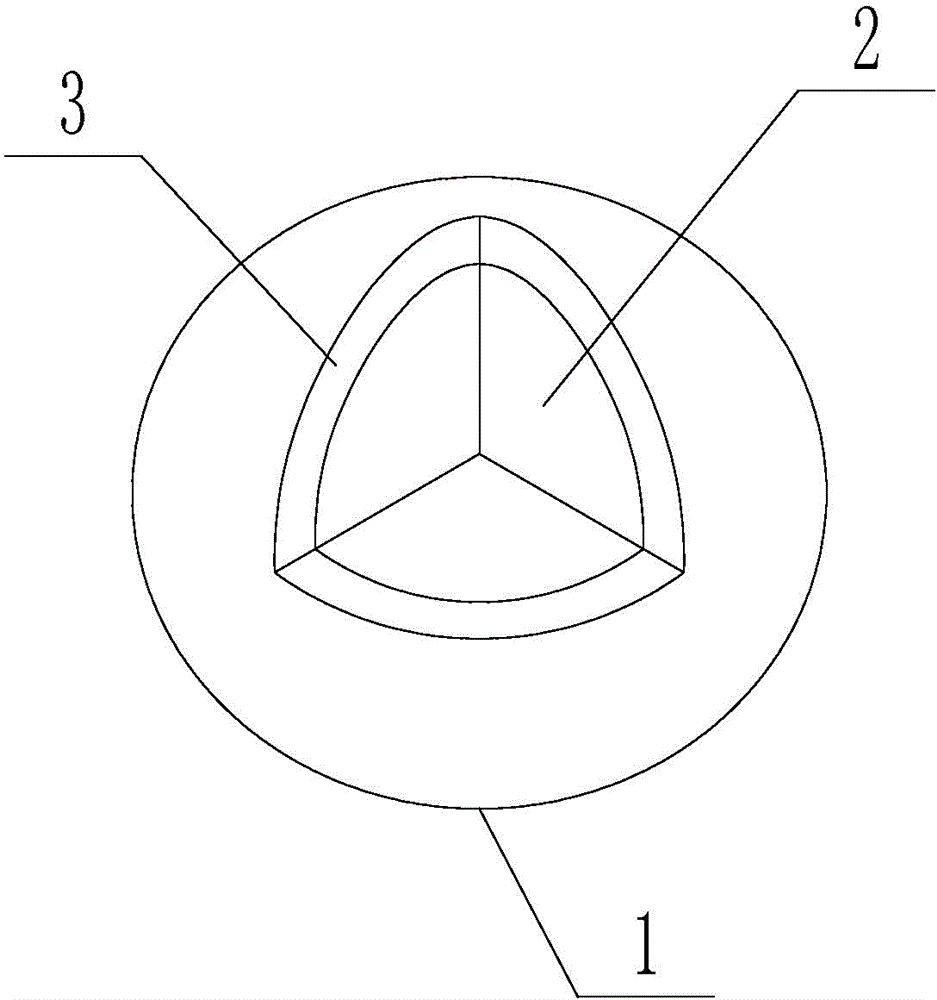

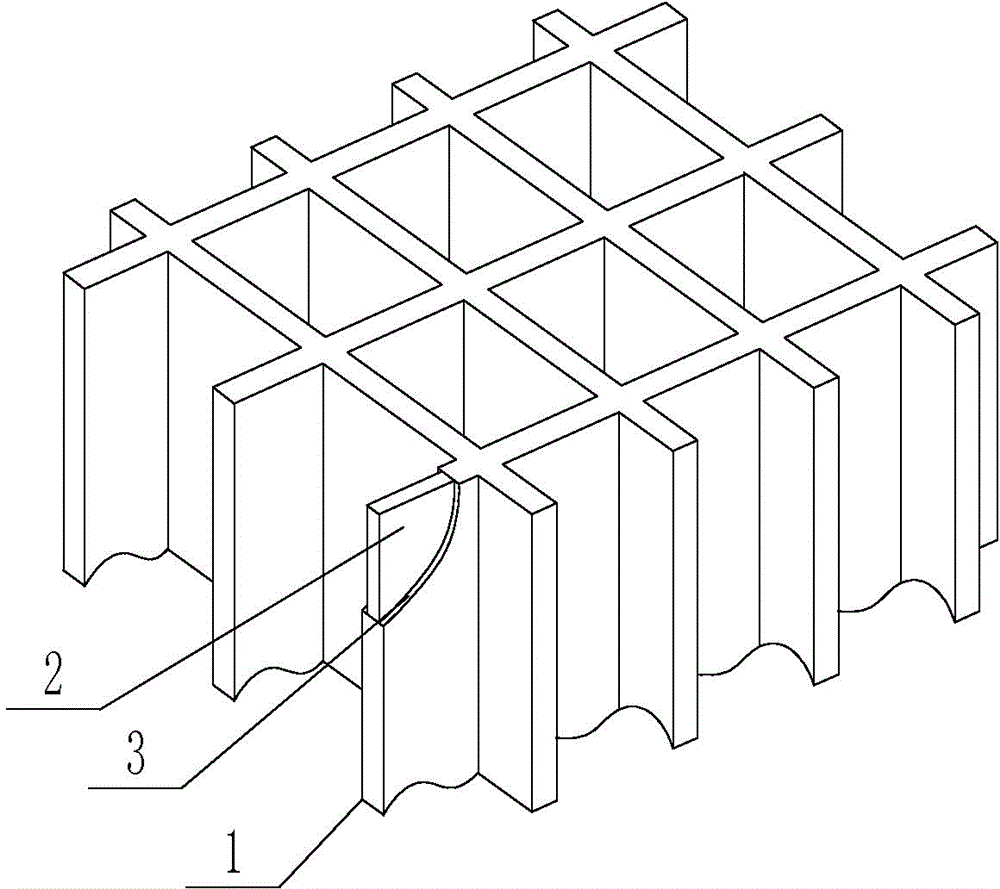

[0021] The composite regenerator includes a regenerator body 1, the cross section of which is a double-layer structure, the inner layer is steel alloy 2, and the outer layer is high alumina 3 (ceramic). Such as figure 1 As shown, the heat storage body body 1 is spherical. The thickness of the outer layer of the regenerator body 1 is greater than 1 mm, and the thickness of the outer layer is between 5% and 30% of the radius of the sphere. Such as figure 2 As shown, the heat storage body body 1 is in the shape of a grid. The thickness of the outer layer of the heat storage body 1 is greater than 1 mm, and the thickness of the outer layer is not higher than 150% of the thickness of the inner layer.

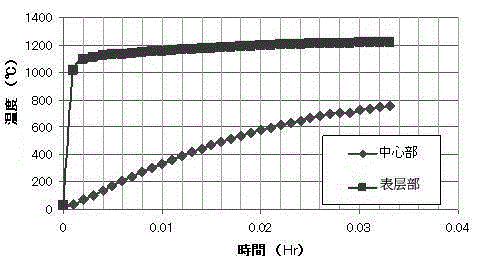

[0022] When the heat storage body is spherical:

[0023] When the regenerative burner adopts a spherical composite regenerator, the appropriate d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com