DRAM device and manufacturing method thereof

A device and storage device technology, applied in the field of DRAM devices and their formation, can solve the problems of poor compatibility, cost, complicated production process of eDRAM devices, etc., and achieve the effect of reducing the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

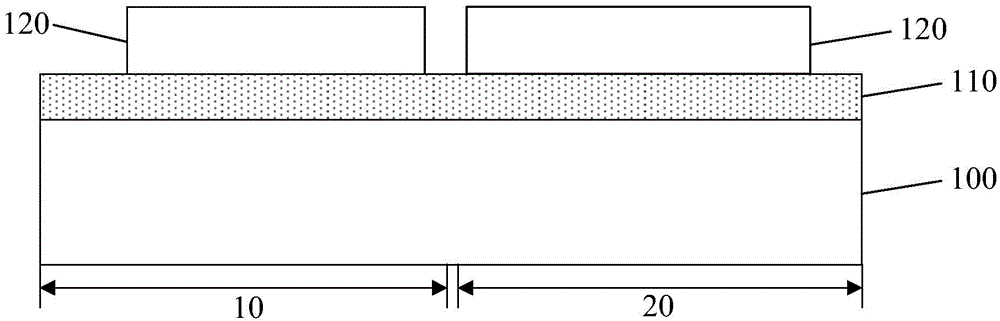

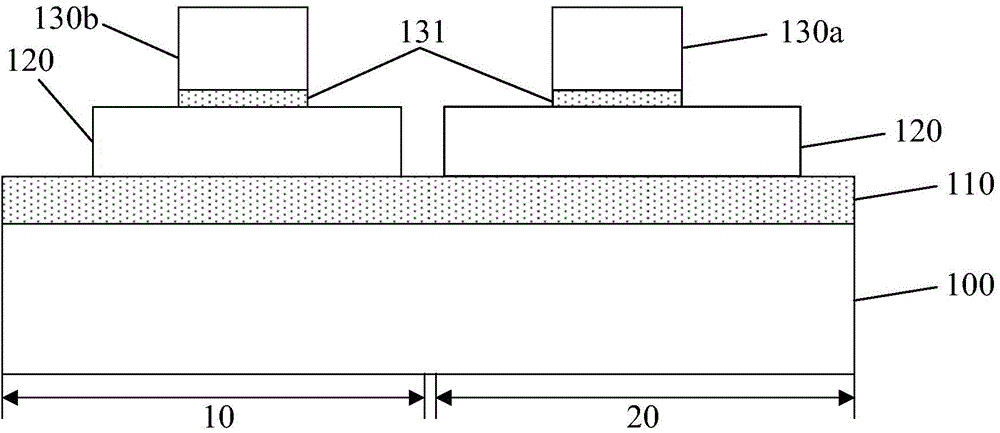

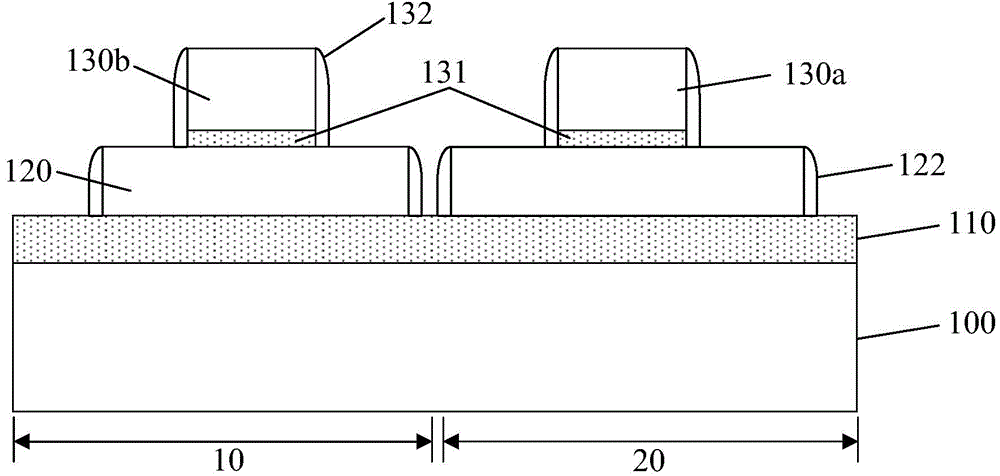

[0054] The process of making eDRAM devices in the prior art is cumbersome, one of the reasons is that the eDRAM devices need to add a capacitor structure in the transistor, and the method used in the prior art is to etch a substrate to form a deep trench (deeptrench ), and then sequentially form a semiconductor layer, a dielectric layer, and a semiconductor layer in the deep trench, so that the semiconductor layer, dielectric layer, and semiconductor layer form the capacitor; after the capacitor is formed, the logic part of the eDRAM device is formed And storage parts, such as gate, source and drain. However, this method is quite different from the current conventional process for manufacturing semiconductors, because the conventional process is generally carried out according to the main steps of substrate-gate-source-drain. After the bottom step, an additional process of forming a capacitor is added, that is to say, the existing process of forming an eDRAM device is not comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com