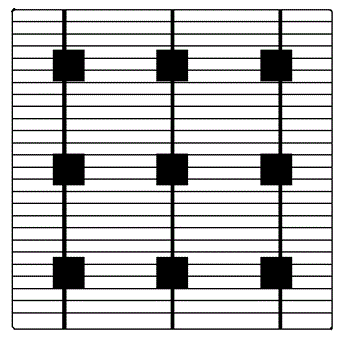

Net plate used for testing sheet resistance after wet etching operation

A wet etching and screen technology, applied in screen printing machines, rotary printing machines, printing and other directions, can solve the problems of unclear imprints, inaccurate square resistance, and differences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Attached below figure 1 The technical solution provided by the present invention is described in further detail.

[0008] In this specific embodiment, taking three busbars as an example, 9 square hollowed-out parts are set on the busbars, and photosensitive glue is coated to prevent wax from passing through the screen; 3 squares are set on each busbar, And the distance between two adjacent squares is equal, so that there are both positive electrode patterns and bare silicon wafers on the printed silicon wafer, so that the square resistance after etching can be accurately tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com