A kind of tea circulating frying and drying machine

A technology for frying and drying tea leaves, which is applied in dryers, non-progressive dryers, drying, etc., and can solve problems such as the inability to clean tea residue, reduce the friction effect of friction wheels, and reduce the pass rate of finished tea products. Achieve the effect of simple structure, reduce breakage rate and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

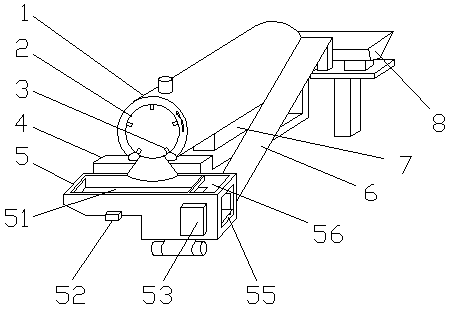

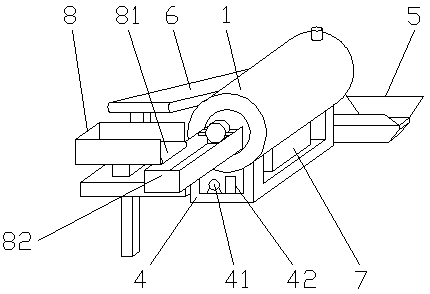

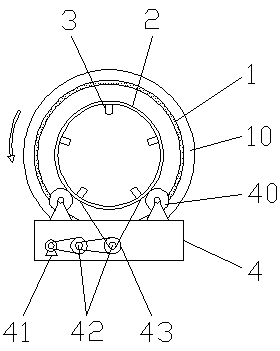

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] As shown in the figure, the technical solution adopted by the present invention to solve its technical problems is: a tea circulation drying machine, including a support frame 4, a circulation transmission device, a heating device 7, a power device, an inner cylinder 2, an outer shell 1, and A number of vane guides 3 spirally arranged in the inner cylinder 2, wherein the section of the vane guides 3 is inverted "V" shape, the purpose is to reduce the impact of the tea leaves on the vane guides 3 during stir-frying The strength makes it easier for the tea to roll after hitting the guide vane plate 3, so that the curling effect of the tea is more perfect.

[0023] A shaping plate 32 is arranged between adjacent vane guide plates 3, and the rotation direction of the shaping plate 32 is opposite to that of the vane guide plate 3, the purpose of this design is to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com