Filter with circulation filtering layer

A filter and filter layer technology, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of not being too strong, poor cleaning effect, low dirt interception ability and filtration precision, etc., and reach the service life Long, easy to replace, improve the effect of interception capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

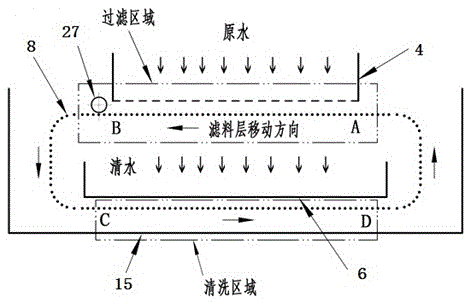

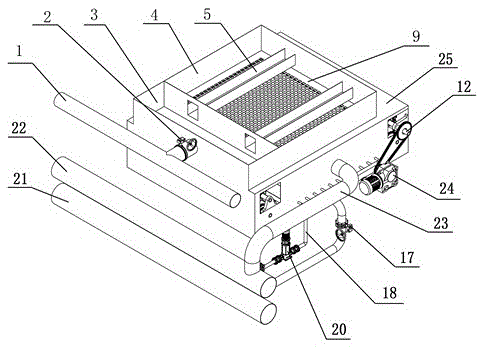

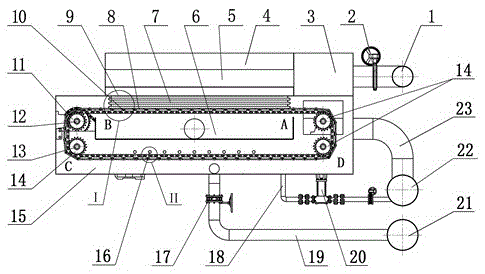

[0018] refer to Figure 1-Figure 5 , the circulating filter layer filter of the present invention comprises a housing 25, a water distribution tank 4 is provided on the top of the housing 25, a front water tank 3 is provided at the front of the water distribution tank 4, and a front water tank 3 is provided in the distribution tank 4. The connected water guide tank 5, the front water tank 3 is connected with the raw water pipe 1 through the water inlet valve 2, the bottom of the water distribution pool 4 has a water distribution orifice plate 9, and the water holes are uniformly arranged on the water distribution orifice plate 9, and the opening ratio is determined according to the amount of treated water. Calculate to ensure the uniformity of water distribution. The upper end of the sealing cover 7 is fixed on the lower end surface of the water distribution orifice 9, and the lower end of the sealing cover 7 is in contact with the upper layer of the circulating filter layer 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com