Frequency conversion dust-free screening and crushing integrated machine

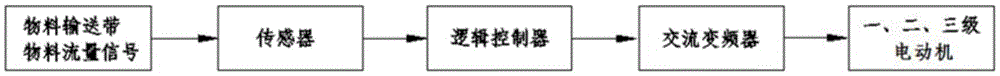

An all-in-one machine and AC frequency conversion technology, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc., can solve the problem of idling or overloading of the three-stage rotor, adjust the rotation of the three-stage crushing roller, increase the consumption of active power, etc. problems, to achieve the effect of easy maintenance, small footprint, and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

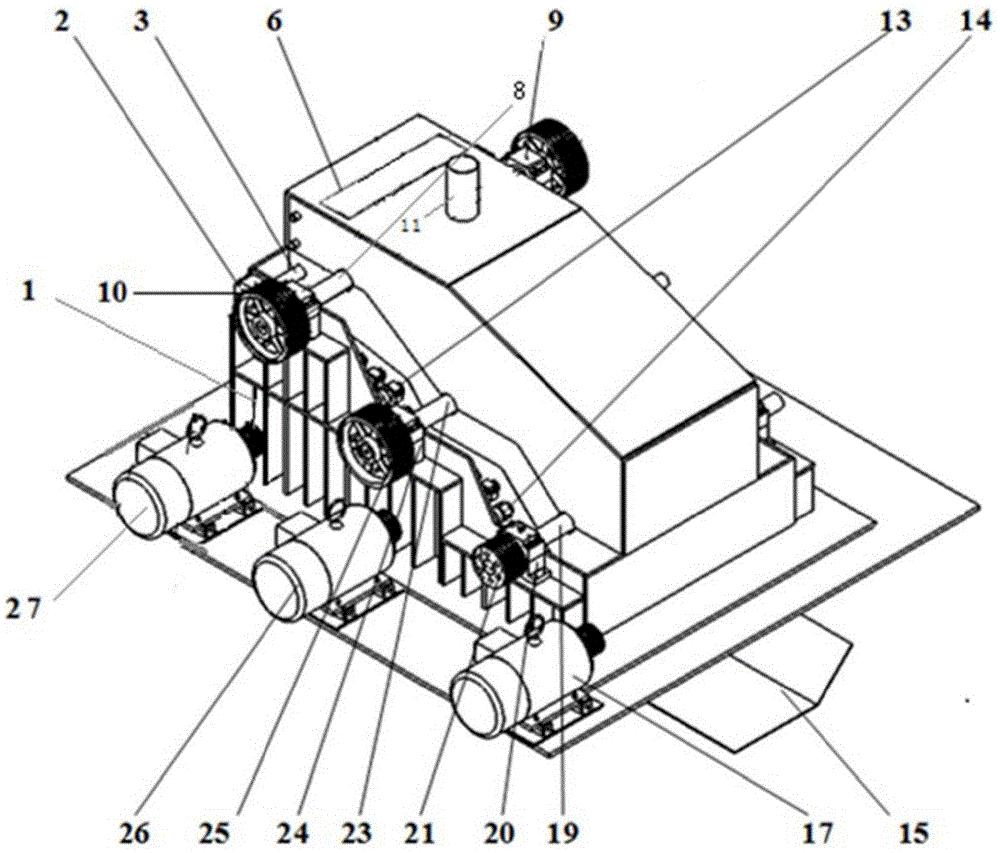

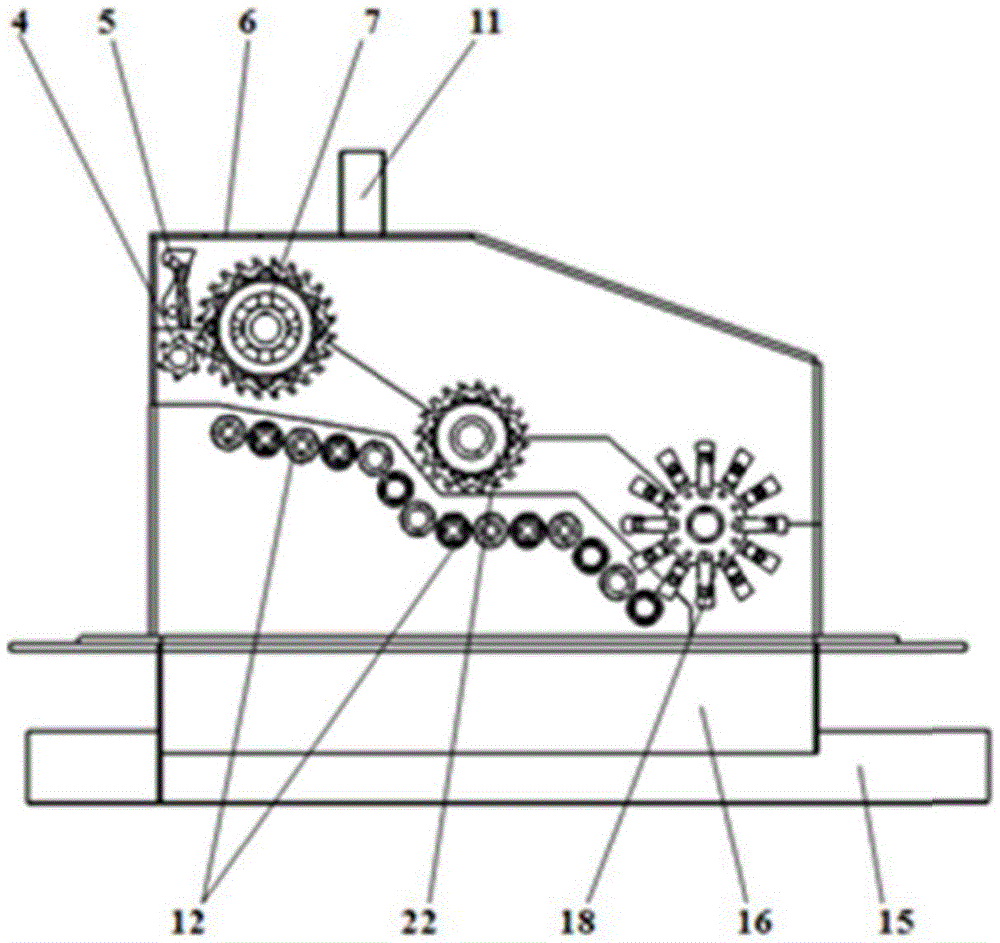

[0036] Such as figure 1 As shown, a frequency conversion dust-free screening and crushing integrated machine includes:

[0037] Frame 1, the frame 1 is stepped, and the upper two sides of the frame 1 are respectively fixed with a first-stage impact roller bearing seat 2, a first-stage roller bearing seat 9, a second-stage roller bearing seat 24, and a third-stage roller bearing. The seat 20 and the sieve roll bearing seat 14; wherein the sieve roll bearing seat 14 is fixed on both sides of the inner side of the frame 1 respectively.

[0038] The primary impact roller 4 is fixed on the primary imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com