A high-precision CNC forming machine tool for spinning traveler

A high-precision, steel traveler technology, applied in the field of textile machinery, can solve the problems that the feeding mechanism does not have automatic feeding, cannot stop feeding in time, and the feeding accuracy is poor, so as to reduce labor costs, simple structure, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

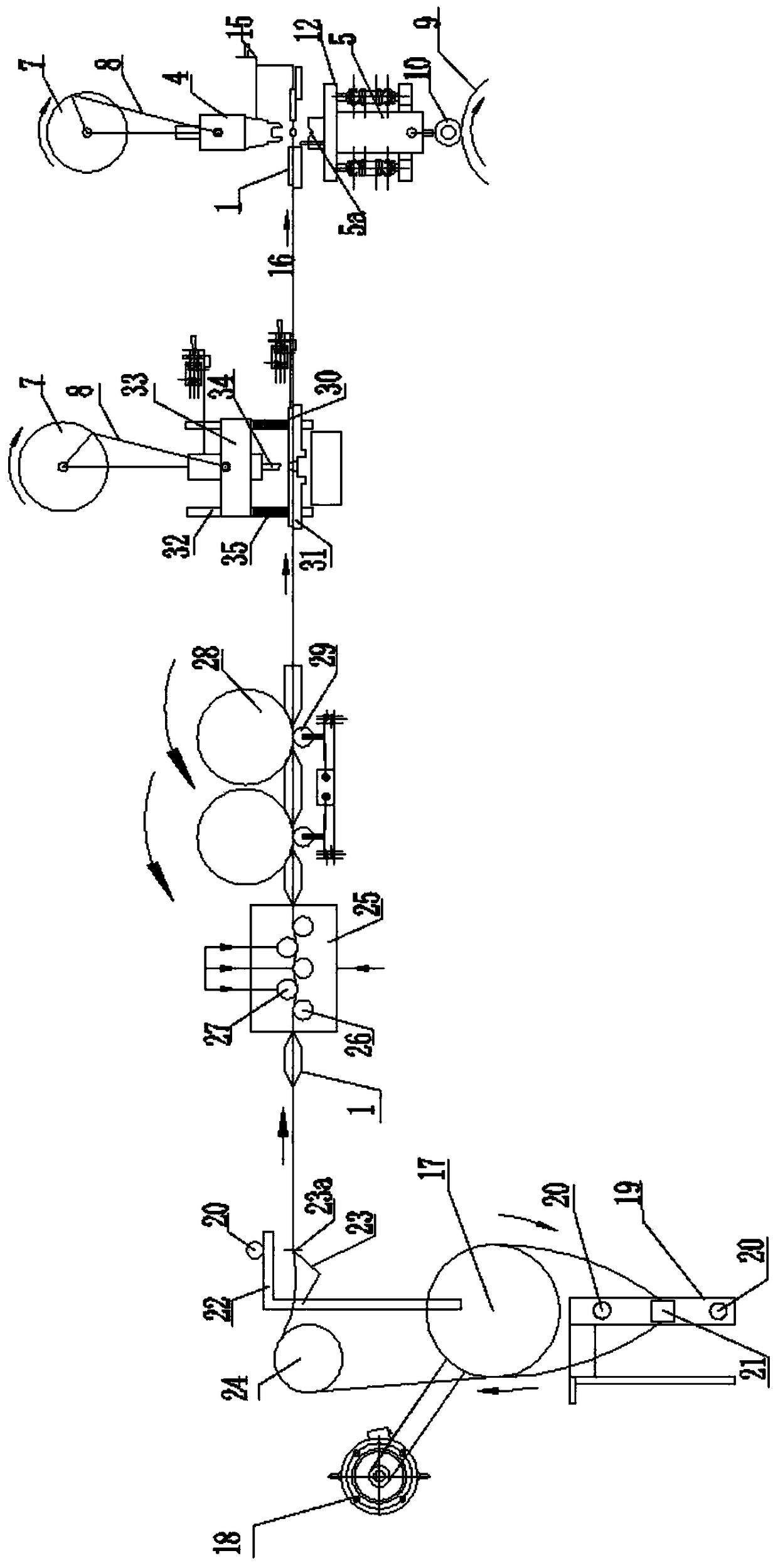

[0032] Example 1, such as Figure 1-7 Shown: the high-precision numerical control forming machine tool for spinning traveler of the present invention is successively made up of blank feeding mechanism, leveling mechanism, blank traction mechanism, punching mechanism and forming mechanism.

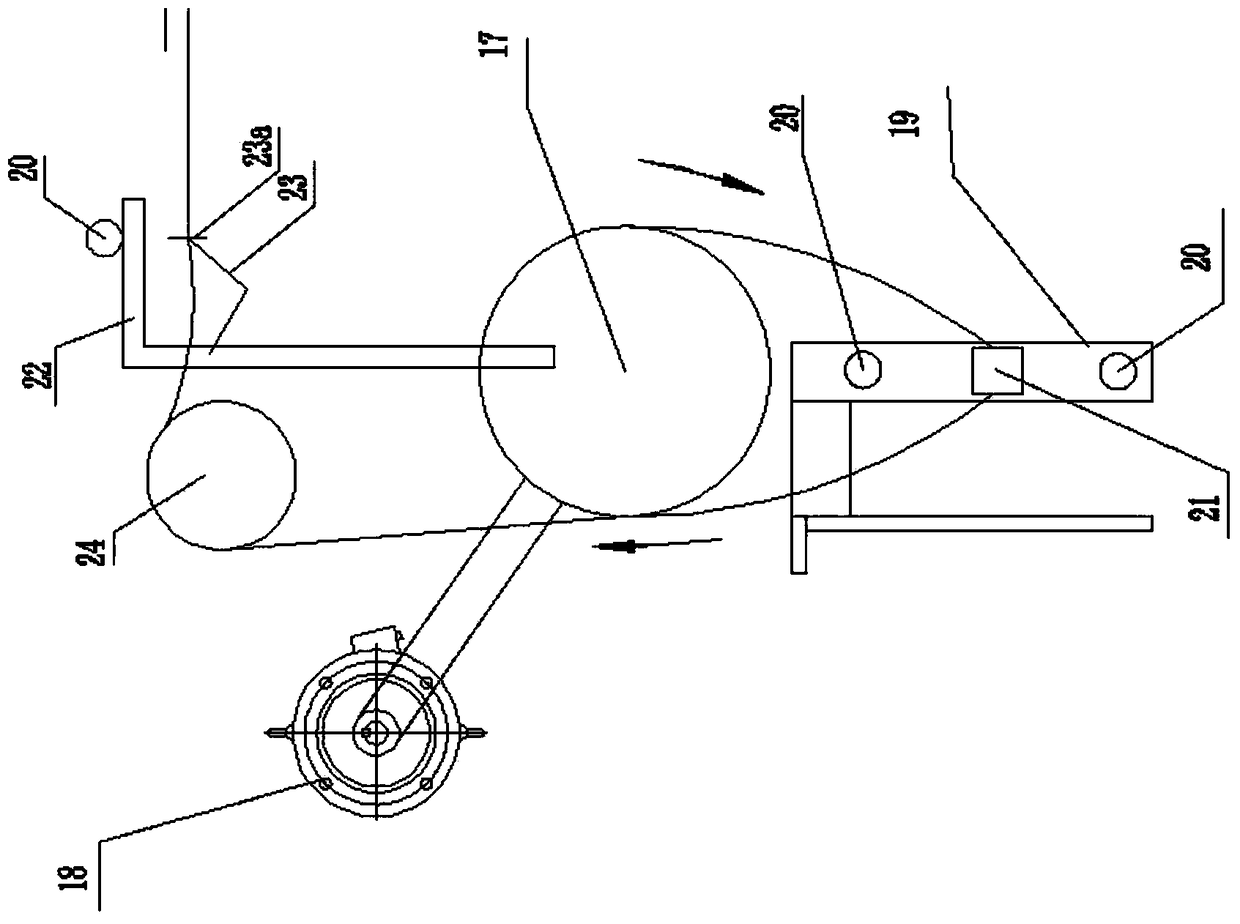

[0033] The discharge mechanism comprises a discharge pan 17 and a motor 18, a pulley is set on the central axis of the discharge pan 17, and a pulley is also set on the output shaft of the reducer of the motor 18, and the belt pulley on the discharge pan 17 and the motor 18 The belt pulley on the speed reducer is connected by a belt, and an upper sheet sensing device and a lower sheet sensing device are respectively arranged below and above the discharging tray 17.

[0034] Wherein the lower sheet sensing device comprises a frame frame 19, and the frame frame 19 includes an upper beam, a lower beam and a longitudinal beam connecting the upper and lower beams, and an inductor 20 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com