A preparation system and method for building recycled materials

A preparation system and construction technology, applied in the direction of climate sustainability, sustainable waste treatment, grain treatment, etc., can solve the problem of fine grinding of buildings that cannot be abandoned, and achieve the effect of expanding the grinding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

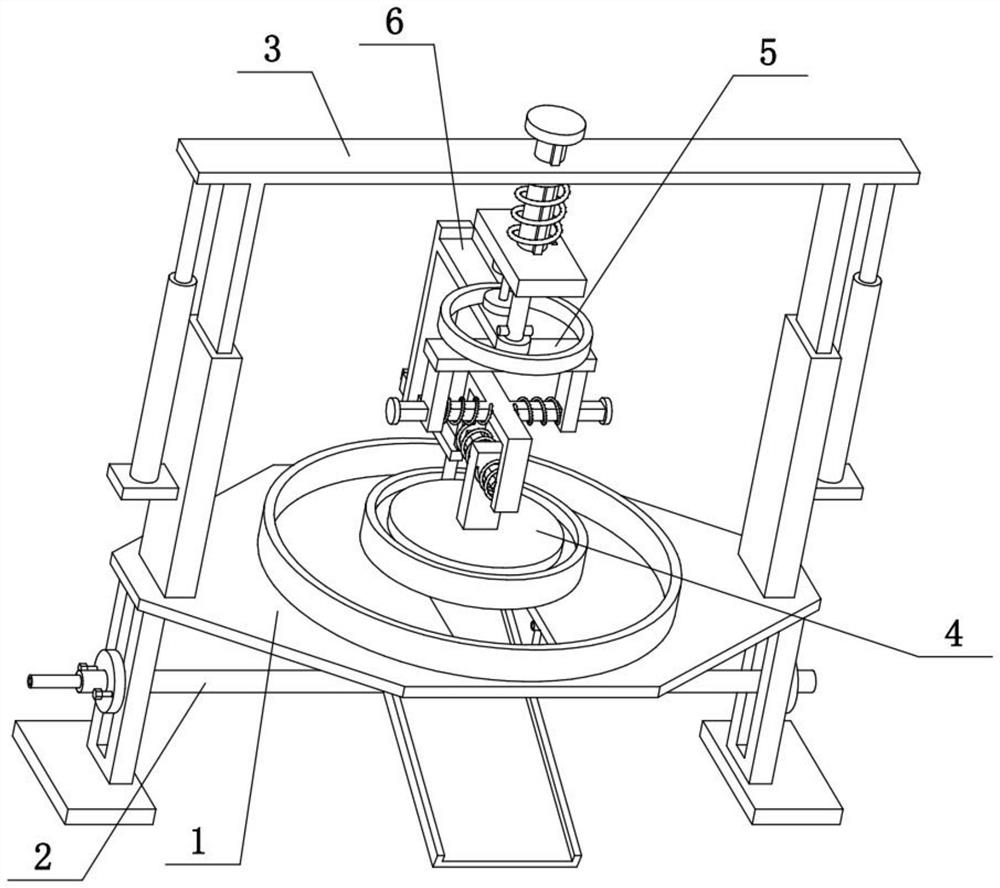

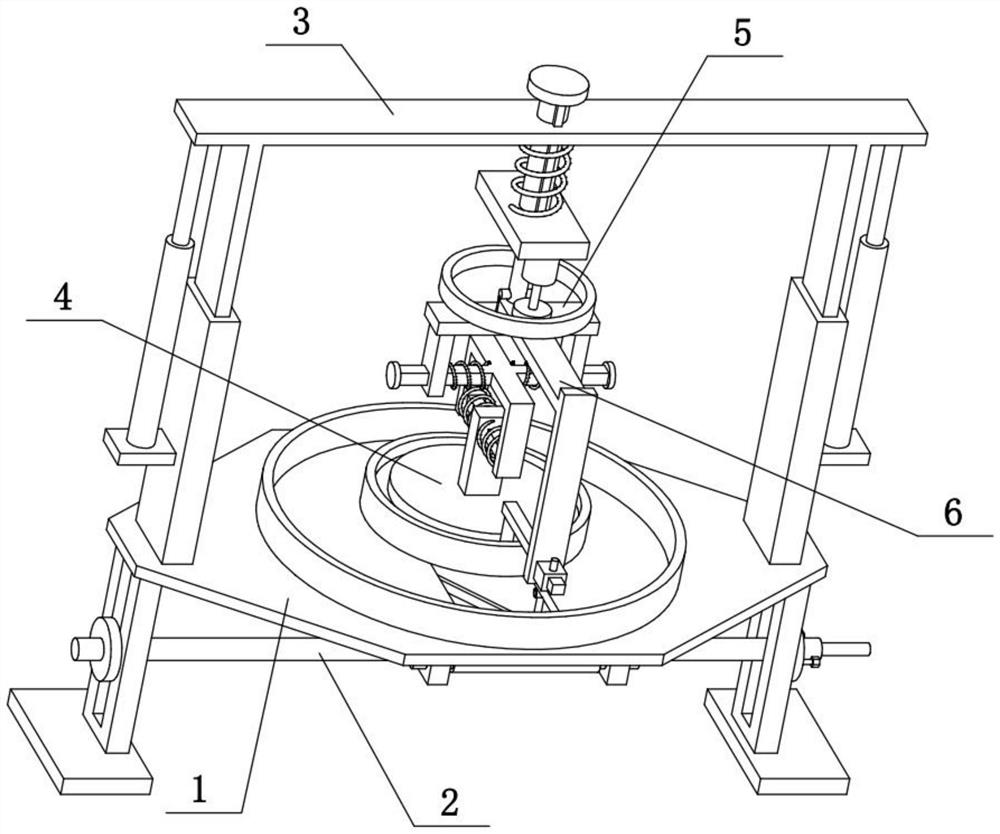

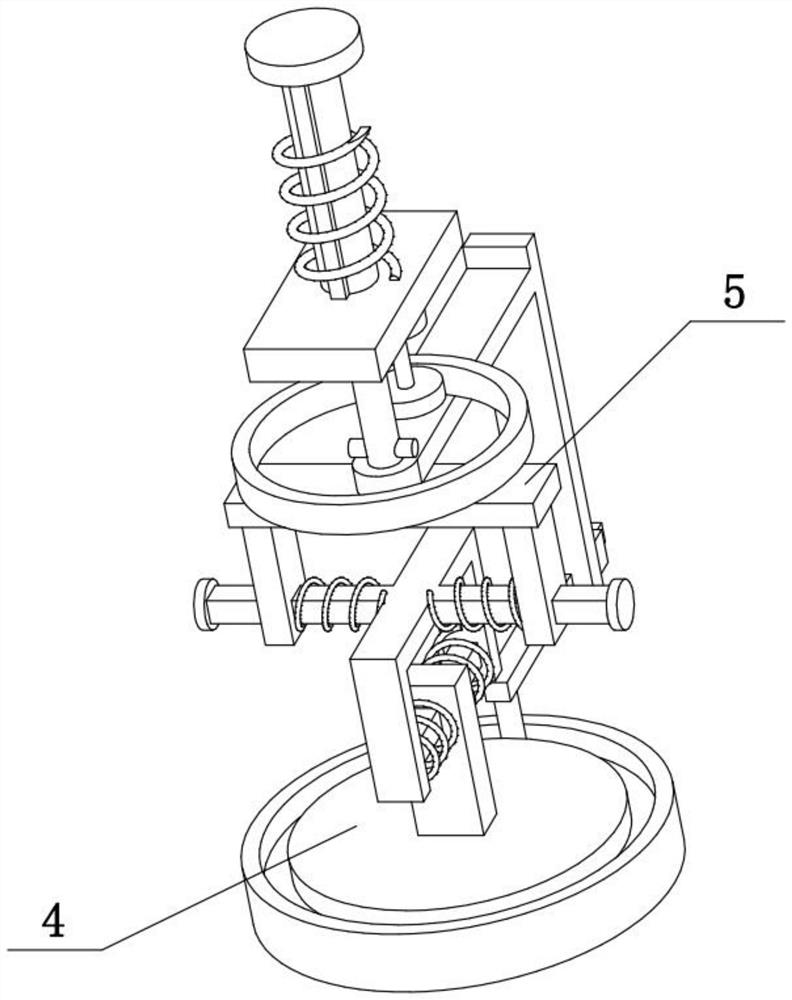

[0034] Combine below Figure 1-9 To illustrate this embodiment, the present invention relates to the field of building recycled materials, more specifically a system and method for preparing building recycled materials, including a flat plate 1, a pressure plate 4, an annular groove 401, a front and rear moving column 402, a stopper 403, Cross column 404, portal frame 405, upright column 406, strip seat 5, lower convex plate 501, fixed shaft 502, flat turning bar 6, vertical connecting bar 601, push-pull column 603 and inserting column 604, the present invention can make abandoned building Finely ground to form a building recycled material.

[0035] The pressure plate 4 is attached to the upper side of the flat plate 1, and the center of the upper side of the pressure plate 4 is fixedly connected with a column 406, and the column 406 is slidably connected with a front and rear moving column 402 in the front and rear direction. A compression spring 1 is socketed, and the two com...

specific Embodiment approach 2

[0036] Combine below Figure 1-9 To illustrate this embodiment, the building regeneration material preparation system also includes a fastening screw II605, the push-pull column 603 is slidably connected to the vertical connecting bar 601, the lower part of the vertical connecting bar 601 is threadedly connected with a fastening screw II605, and the fastening screw II605 The push-pull column 603 is fixed on the push-pull column 603 . The push-pull column 603 can slide on the vertical connecting bar 601, and then drive the insertion cylinder 604 to move, and then adjust the distance between the axis of the insertion cylinder 604 and the axis of the fixed shaft 502, the greater the distance between the axis of the insertion cylinder 604 and the axis of the fixed shaft 502 , the larger the coverage area of the platen 4 moving along a circular trajectory, the larger the abandoned buildings on the plate 1 can be ground.

specific Embodiment approach 3

[0037] Combine below Figure 1-9 To illustrate this embodiment, the building regeneration material preparation system also includes a flat seat 506, a motor 507, a gear 508, a stop pin 509 and a gear ring 602. 502 is set coaxially, the fixed shaft 502 is fixedly connected with a stop pin 509, the stop pin 509 is located on the upper side of the pan bar 6, the upper part of the fixed shaft 502 is fixedly connected with a flat seat 506, and the lower side of the flat seat 506 is fixedly connected with a motor 507 , a gear 508 is fixedly connected to the output shaft at the lower end of the motor 507 , and the gear 508 is meshed with the inner ring of the gear ring 602 for transmission. When the motor 507 rotates, it can drive the gear 508 to rotate. When the gear 508 rotates, it drives the gear ring 602 to rotate. Rotate, and then drive the platen 4 to translate along a circular track, and finely grind the construction waste on the plate 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com