Wear-resistant high-precision self-centering chuck

A self-centering chuck, high-precision technology, applied to chucks, turning equipment, tool holder accessories, etc., can solve the problems of incomplete sealing, small number of teeth, and difficult clamping of disc parts, so as to prolong the service life , The effect of extending the distance of the wire teeth and increasing the number of wire teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

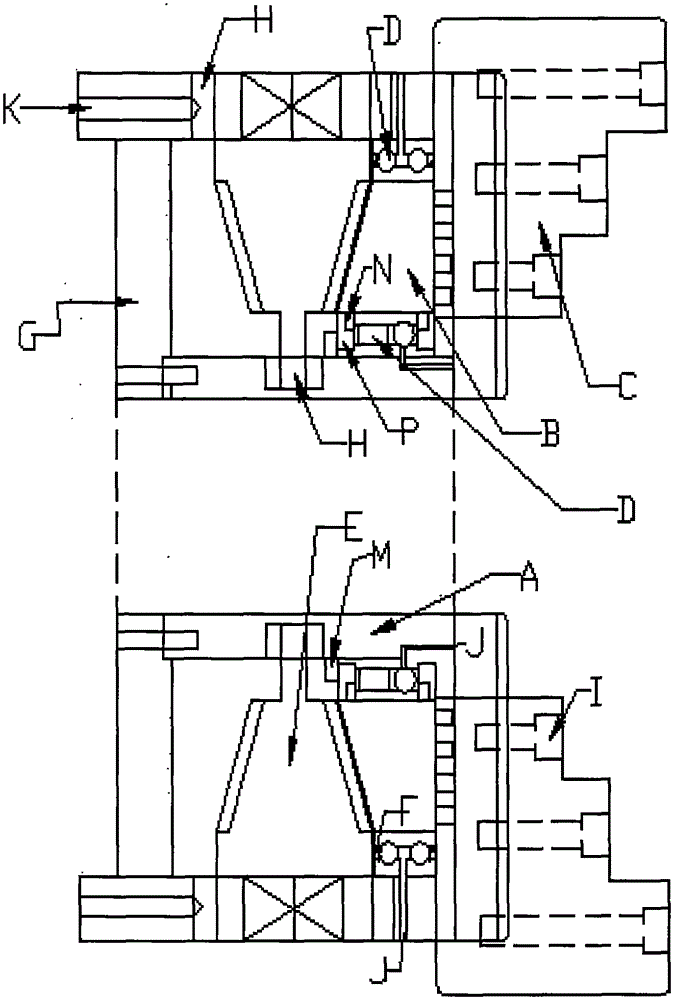

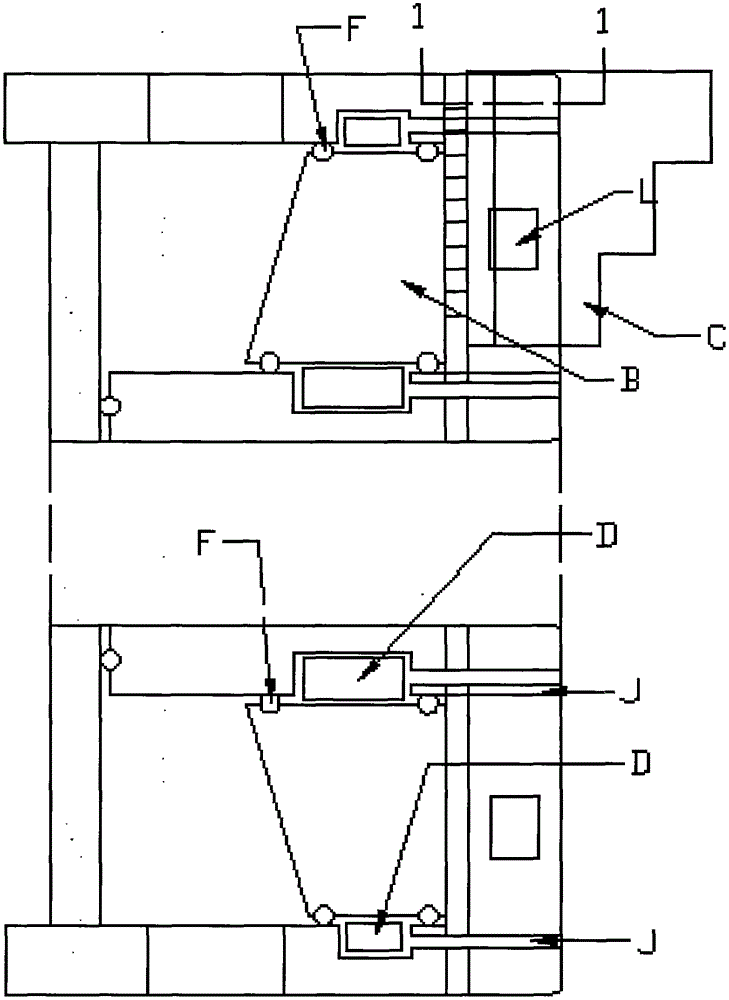

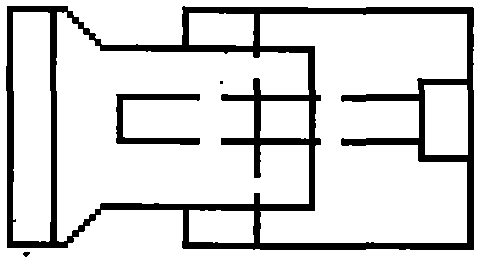

[0019] Below in conjunction with accompanying drawing, this design is described in detail.

[0020] Such as Figure 1 to Figure 23 Shown; a wear-resistant high-precision self-centering chuck. It consists of a chuck body, a coil body, claws, rolling guides, bevel gears, sealing rings or sealing tapes or sealing rings, side seals, garbage baffles, balls or bearings or bushings, claw fastening screws , lubricating oil circuit, anti-out pin, oil storage block, cylindrical pins or conical pins or ball pins or oval pins, fastening ring or circlip, outer ring of magnetic block, cast iron block, copper sheet, permanent magnet and other components. The chuck body is a sunken cavity formed between the outer convex and the inner boss, and a bevel gear is installed in the sunken cavity. The bevel gear can be a traditional bevel gear or a new bevel gear as shown in the figure. Bevel gear, the two ends of the bevel gear are equipped with marbles or bushings or bearings, which are tightly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com