Numerically-controlled part adding tool and rapid assembling method thereof

An assembly method and tooling technology, which is applied in the field of mechanical processing, can solve the problems of tooling manufacturing, long turnover period, low work efficiency, and large task load, and achieve the effects of high manufacturing and assembly precision, intuitive detection, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

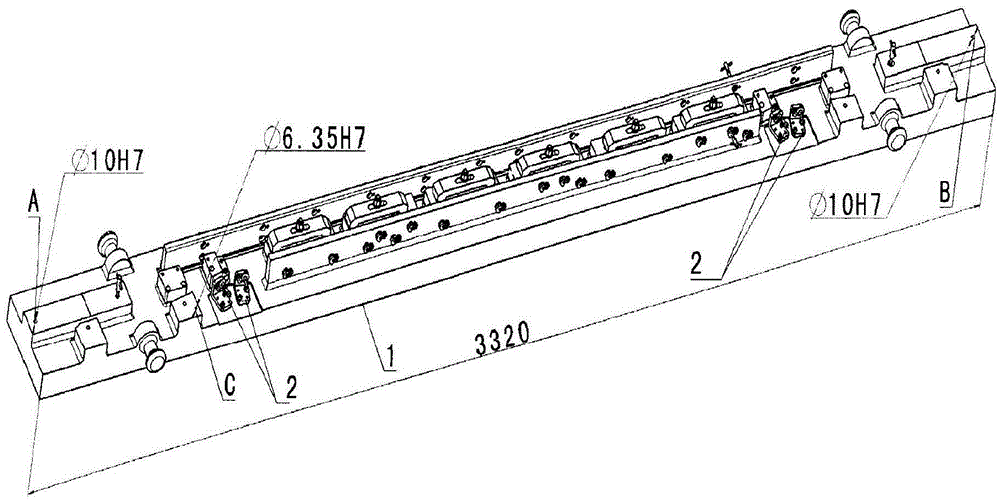

[0025] Such as figure 1 The structure diagram of a CNC add-on tooling is shown, which has a tooling base body 1. The tooling base body 1 has a reference hole AΦ10H7 and a reference hole BΦ10H7. The tooling base body 1 also has a processed surface. It is necessary to add 4 A drill template2.

[0026] A rapid assembly method for numerically controlled add-on tooling, specifically comprising the following steps:

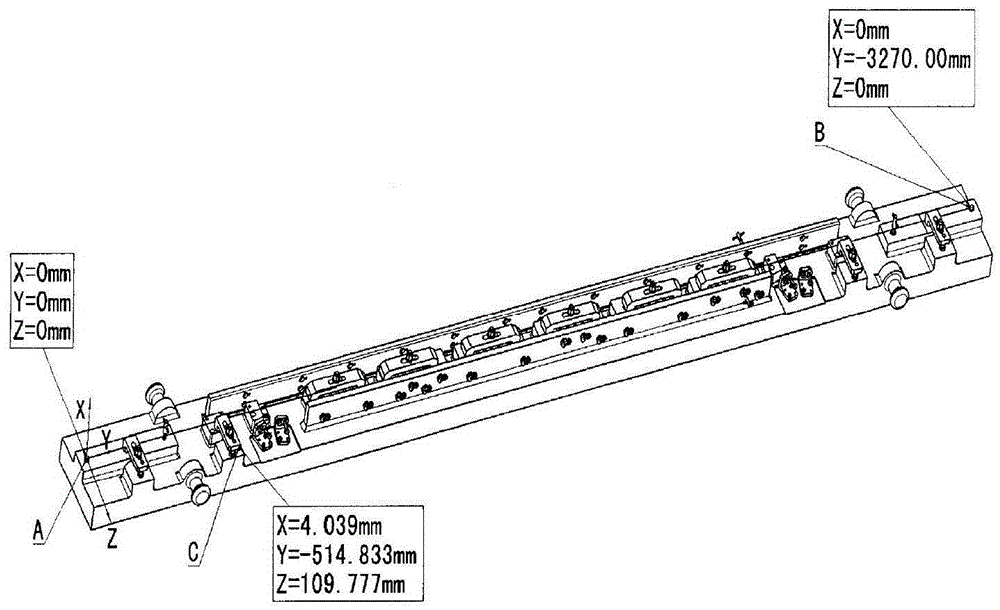

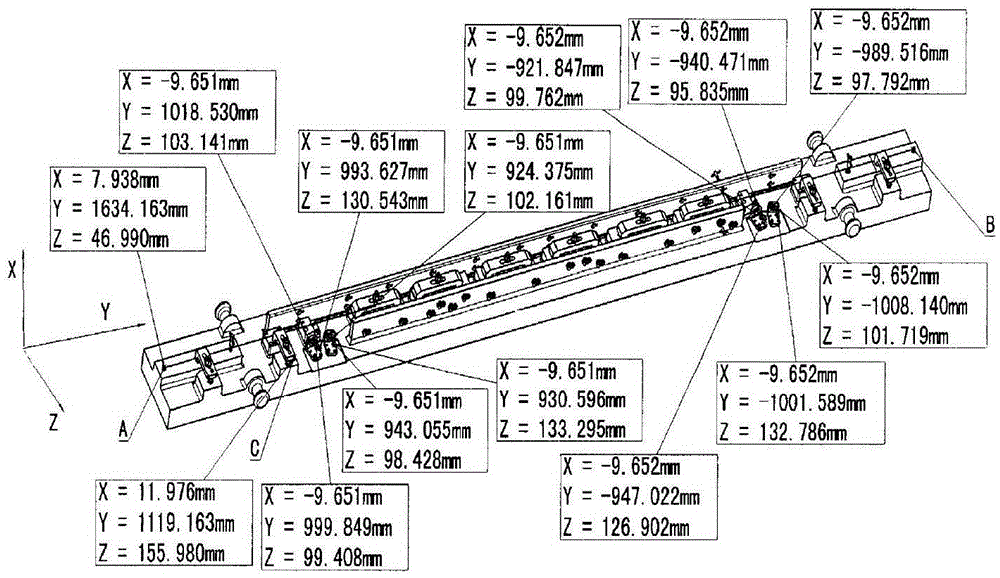

[0027] 1) Add auxiliary reference hole C on the tooling base 1: Drill a Φ6.35H7 hole at any position on the processed surface of the tooling base 1 (this hole is consistent with the diameter of the tool ball target ball base of the laser tracker), as an auxiliary Reference hole C. Using the original reference hole AΦ10H7 and reference hole BΦ10H7 can complete the indirect use of three points by the laser tracker, and then use the instrument to establish an axis-aligned coordinate system to measure the relative position of the three points, as shown in figure 2 shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com